Hardware Manual - phyBOARD-Nunki i.MX 6 (L-852e.A3)

Table of Contents

Copyrighted products are not explicitly indicated in this manual. The absence of the trademark (™ or ®) and copyright (©) symbols does not imply that a product is not protected. Additionally, registered patents and trademarks are similarly not expressly indicated in this manual.

The information in this document has been carefully checked and is considered to be entirely reliable. However, PHYTEC Messtechnik GmbH assumes no responsibility for any inaccuracies. PHYTEC Messtechnik GmbH neither gives any guarantee nor accepts any liability whatsoever for consequential damages resulting from the use of this manual or its associated product. PHYTEC Messtechnik GmbH reserves the right to alter the information contained herein without prior notification and accepts no responsibility for any damages that might result.

Additionally, PHYTEC Messtechnik GmbH offers no guarantee nor accepts any liability for damages arising from the improper usage or improper installation of the hardware or software. PHYTEC Messtechnik GmbH further reserves the right to alter the layout and/or design of the hardware without prior notification and accepts no liability for doing so.

@ Copyright 2020 PHYTEC Messtechnik GmbH, D-55129 Mainz.

Rights - including those of translation, reprint, broadcast, photomechanical or similar reproduction and storage or processing in computer systems, in whole or in part - are reserved. No reproduction may occur without the express written consent from PHYTEC Messtechnik GmbH.

| EUROPE | NORTH AMERICA | FRANCE | INDIA | CHINA |

Address: | PHYTEC Messtechnik GmbH | PHYTEC America LLC | PHYTEC France | PHYTEC Embedded Pvt. Ltd | PHYTEC Information Technology (Shenzhen) Co. Ltd. |

Ordering Information: | +49 6131 9221-32 | +1 800 278-9913 | +33 2 43 29 22 33 | +91-80-4086 7046/48 sales@phytec.in | +86-755-3395-5875 sales@phytec.cn |

Technical Support: | +49 6131 9221-31 | +1 206 780-9047 | +91-80-4086 7047 support@phytec.in | support@phytec.cn | |

Fax: | +49 6131 9221-33 | +1 206 780-9135 | +33 2 43 29 22 34 | +86-755-3395-5999 | |

Web Site: | http://phytec.in | http://www.phytec.cn |

Conversions, Abbreviations, and Acronyms

This hardware manual describes the PB-02013-XXX Single Board Computer (SBC), henceforth referred to as phyBOARD‑Nunki i.MX 6. This manual specifies the phyBOARD‑Nunki i.MX 6's design and function. Precise specifications for the NXP® Semiconductor i.MX 6 microcontrollers can be found in the NXP® Semiconductor’s i.MX 6 Data Sheet and Technical Reference Manual.

Conventions

The conventions used in this manual are as follows:

- Signals that are preceded by an "n", "/", or “#”character (e.g.: nRD, /RD, or #RD), or that have a dash on top of the signal name (e.g.: RD) are designated as active low signals. That is, their active state is when they are driven low, or are driving low.

- A "0" indicates a logic zero or low-level signal, while a "1" represents a logic one or high-level signal.

- The hex-numbers given for addresses of I2C devices always represent the 7 MSB of the address byte. The correct value of the LSB which depends on the desired command (read (1), or write (0)) must be added to get the complete address byte. E.g. given address in this manual 0x41 => complete address byte = 0x83 to read from the device and 0x82 to write to the device.

- Tables which describe jumper settings show the default position in bold,bluetext.

- Text in blue indicates a hyperlink within, or external to the document. Click these links to quickly jump to the applicable URL, part, chapter, table, or figure.

- Text in bold italic indicates an interaction by the user, which is defined on the screen.

- Text in italic indicates proper names of development tools and corresponding controls (windows, tabs, commands etc.) used within the development tool, no interaction takes place.

Types of Signals

Different types of signals are brought out at the phyCORE-Connector. Refer to the SOM manual for pin muxing options.

Signal Type | Description | Abbr. |

Power Input | Supply voltage input | PWR_I |

Power Output | Supply voltage output for external devices | PWR_O |

Ref-Voltage | Reference voltage output | REF_O |

Input | Digital input | I |

Output | Digital output | O |

Input / output | Bidirectional input/output | I/O |

OD-Bidir PU | Open drain input/output with pull‑up resistor | OD-BI |

LVDS Output | Differential line pairs 100 Ohm LVDS level output | LVDS_O |

LVDS Input | Differential line pairs 100 Ohm LVDS level input | LVDS_I |

USB-Power | USB voltage | USB |

USB IO | Differential line pairs 90 Ohm USB level bidirectional input/output | USB_I/O |

Ethernet IO | Differential line pairs 100 Ohm Ethernet level bidirectional input/output | ETH_I/O |

Analog | Analog input or output | Analog |

Signal Types used in this Manual

Abbreviations and Acronyms

Many acronyms and abbreviations are used throughout this manual.

Abbreviation | Definition |

A/V | Audio/Video |

BSP | Board Support Package (Software delivered with the Development Kit including an operating system (Windows, or Linux) pre-installed on the module and Development Tools) |

CB | Carrier Board, used in reference to the phyBOARD‑Nunki Development Kit Carrier Board |

DFF | D flip-flop |

DSC | Direct Solder Connect |

EMB | External memory bus |

EMI | Electromagnetic Interference |

GPIO | General purpose input and output |

GPO | General purpose output |

J | Solder jumper, these types of jumpers require solder equipment to remove and place |

JP | Solderless jumper, these types of jumpers can be removed and placed by hand with no special tools |

NC | Not Connected |

NM | Not Mounted |

NS | Not Specified |

PCB | Printed circuit board |

UDI | Universal Display Interface, defined to connect custom display adapters with or without touch screen |

PEB | PHYTEC Expansion Board |

POR | Power-on reset |

RTC | Real-time clock |

SBC | Single Board Computer, used in reference to the PBA-CD-10 / phyBOARD‑Nunki i.MX 6 |

SMT | Surface mount technology |

SOM | System on Module, used in reference to the PCL-063 / phyCORE‑i.MX 6 module |

Sx | User button Sx (e.g. S1, S2) used in reference to the available user buttons, or DIP switches on the CB |

Sx_y | Switch y of DIP switch Sx, used in reference to the DIP switch on the carrier board |

Abbreviations and Acronyms used in this Manual

Tip

The BSP is configured according to the hardware configuration including the expansion board optionally delivered with the kit. Some functions of the phyBOARD-Nunki°i.MX 6 might not be available at the corresponding pins and drivers are needed to support an expansion board. If the expansion board is removed or exchanged, the BSP must be exchanged as well.

Preface

As a member of PHYTEC's phyBOARD® product family, the phyBOARD‑Nunki i.MX 6 is one of a series of PHYTEC System on Modules (SBCs) that offer off-the-shelf solutions for a huge variety of industrial applications. The new phyBOARD® product family consists of a series of extremely compact embedded control engines featuring various processing performance classes. All phyBOARDs are rated for industry, cost optimized, and offer long-term availability. The phyBOARD‑Nunki i.MX 6 is one of currently six industrial-grade carrier boards which are suitable for series production and that has been realized in accordance with PHYTEC's new SBCplus concept. It is an excellent example of this concept.

SBC plus Concept

The SBCplus concept was developed to meet various differences in customer requirements with little development effort. This greatly reduces the time-to-market.

The core of the SBCplus concept is the SBC design library (a kind of construction set) that consists of a large number of function blocks (so-called "building blocks") which are constantly being refined. The recombination of these function blocks allows PHYTEC to develop a customer specific SBC within a short time. PHYTEC is able to deliver production-ready custom Single Board Computers within a few weeks at very low costs.

Existing SBCs, such as the phyBOARD‑Nunki i.MX 6, each represent an intersection of different customer wishes. Due to this, all necessary interfaces are available on the standard versions, allowing them to be integrated in a large number of applications without modification. For any specific adjustments that are needed, extension connectors are available to add a wide variety of functions.

Customized Expandability from PHYTEC

Common interface signals route to standard connector interfaces on the carrier board such as Ethernet, CAN, RS-232, and audio. Due to the easily modifiable phyBOARD design approach (see "SBCplus concept"), these plug-and-play interfaces can be readily adapted into customer-specific variants according to end system requirements.

Some signals from the processor populating the SOM also extend to the expansion and A/V connectors of the phyBOARD‑Nunki i.MX 6. This provides customized expandability according to end user requirements. Expandability is made easy by available plug-and-play expansion modules (for example Parallel Displays) from PHYTEC.

The default orientation of the expansion bus connectors is parallel and on the top side of the carrier board PCB. However, in custom configurations, the connectors can be mounted on the PCB's underside. Connectors in perpendicular orientation can also populate the top or underside of the PCB. This enables maximum flexibility for the orientation of expansion modules on the phyBOARD‑Nunki i.MX 6, as well as easily integrating the system into a variety of end application physical envelopes and form factors.

Easy Integration of Displays and Touchscreens

The phyBOARD and its expansion modules enable easy connection of parallel or LVDS based displays, as well as resistive or capacitive touchscreens.

OEM Implementation

Implementing an OEM-able SBC subassembly as the "core" of your embedded design allows for increased focus on hardware peripherals and firmware without expending resources to "re-invent" microcontroller circuitry. Furthermore, much of the value of the phyBOARD® SBC lies in its layout.

Software Support

Production-ready Board Support Packages (BSPs) and Design Services for PHYTEC hardware will further reduce development time and risk and allow for increased focus on the product expertise.

Ordering Information

| phyBOARD‑Nunki i.MX 6 Development Kit: | KPB-02301-xxx |

| phyBOARD‑Nunki i.MX 6 SBC: | PB-02301-xxx |

| phyCORE-i.MX 6 SOM: | PCM-058 |

Product Specific Information and Technical Support

In order to receive product specific information on all future changes and updates, we recommend registering at:

http://www.phytec.de/de/support/registrierung.html

or

http://www.phytec.eu/europe/support/registration.html

For technical support and additional information concerning your product, please visit the download section of our web site which provides product specific information such as errata sheets, application notes, FAQs, etc.

http://www.phytec.de/produkt/single-board-computer/phyboard-nunki-download/

or

http://www.phytec.eu/europe/support/faq/faq-phyBOARD-Nunki-i.MX6.html

Other Products and Development Support

Apart from the new phyBOARD® family, PHYTEC supports a variety of 8-/16- and 32-bit controllers in two ways:

(1) As the basis for Rapid Development Kits, which serve as a reference and evaluation platform

(2) As insert-ready, fully functional OEM modules which can be embedded directly into the user’s peripheral hardware design.

Take advantage of PHYTEC products to shorten time-to-market, reduce development costs, and avoid substantial design issues and risks. With this new innovative full system solution new ideas can be brought to market in the most timely and cost-efficient manner.

For more information, go to:

http://www.phytec.de/de/leistungen/entwicklungsunterstuetzung.html

or

http://www.phytec.eu/europe/oem-integration/evaluation-start-up.html

Declaration of Electromagnetic Conformity of the PHYTEC phyBOARD®‑Nunki i.MX 6

PHYTEC System on Module (henceforth products) are designed for installation in electrical appliances or as dedicated Evaluation Boards (i.e.: for use as a test and prototype platform for hardware/software development) in laboratory environments.

Warning

PHYTEC products lacking protective enclosures are subject to damage by ESD and, therefore, must be unpacked, handled, or operated in environments in which sufficient precautionary measures have been taken in respect to ESD dangers. Only appropriately trained personnel such as qualified electricians, technicians, and engineers should handle and/or operate these products. Moreover, PHYTEC products should not be operated without protection circuitry if connections to the product's pin header rows are longer than 3 m.

PHYTEC products fulfill the norms of the European Union’s Directive for Electromagnetic Conformity in accordance with the descriptions and rules of usage indicated in this hardware manual (particularly in respect to the pin header row connectors, power connector, and serial interface to a host PC).

Tip

Implementation of PHYTEC products into target devices, as well as user modifications and extensions of PHYTEC products, is subject to renewed establishment of conformity to and certification of Electromagnetic Directives. Users should ensure conformity following any modifications to a product as well as implementation of a product into target systems.

Product Change Management and Information Regarding Parts Populated on the SOM / SBC

With the purchase of a PHYTEC SOM / SBC you will, in addition to our hardware and software possibilities, receive free obsolescence maintenance service for the hardware we provide. Our PCM (Product Change Management) team of developers is continuously processing all incoming PCN's (Product Change Notifications) from vendors and distributors concerning parts which are used in our products. Possible impacts to the functionality of our products due to changes of functionality or obsolesce of certain parts are constantly being evaluated in order to take the right measures either in purchasing decisions or within our hardware / software design.

Our general philosophy here is: We will never discontinue a product as long as there is demand for it.

To fulfill this, we have established a set of methods to fulfill our philosophy:

Avoidance strategies:

- Avoid changes by evaluating longevity of parts during design-in phase.

- Ensure availability of equivalent second source parts.

- Stay in close contact with part vendors to keep up with roadmap strategies.

Change management in rare event of an obsolete and non-replaceable part:

- Ensure long term availability by stocking parts through last time buy management according to product forecasts.

- Offer long term frame contract to customers.

Change management in cases of functional changes:

- Avoid impacts on product functionality by choosing equivalent replacement parts.

- Avoid impacts on product functionality by compensating changes through hardware redesign or backward compatible software maintenance.

- Provide early change notifications concerning functional, relevant changes of our products.

We refrain from providing detailed part specific information within this manual, which can be subject to continuous changes, due to part maintenance for our products.

In order to receive reliable, up-to-date, and detailed information concerning parts used for our product, please contact our support team through the contact information given within this manual.

PHYTEC Documentation

PHYTEC will provide a variety of hardware and software documentation for all of our products. This includes any or all of the following:

- QS Guide: A short guide on how to set up and boot a phyCORE board along with brief information on building a BSP, the device tree, and accessing peripherals.

- Hardware Manual: A detailed description of the System on Module and accompanying carrier board.

- Yocto Guide: A comprehensive guide for the Yocto version the phyCORE uses. This guide contains an overview of Yocto; introducing, installing, and customizing the PHYTEC BSP; how to work with programs like Poky and Bitbake; and much more.

- BSP Manual: A manual specific to the BSP version of the phyCORE. Information such as how to build the BSP, booting, updating software, device tree, and accessing peripherals can be found here.

- Development Environment Guide: This guide shows how to work with the Virtual Machine (VM) Host PHYTEC has developed and prepared to run various Development Environments. There are detailed step-by-step instructions for Eclipse and Qt Creator, which are included in the VM. There are instructions for running demo projects for these progams on a phyCORE product as well. Information on how to build a Linux host PC yourself is also a part of this guide.

- Pin Muxing Table: phyCORE SOMs have an accompanying pin table (in Excel format). This table will show the complete default signal path, from processor to carrier board. The default device tree muxing option will also be included. This gives a developer all the information needed in one location to make muxing changes and design options when developing a specialized carrier board or adapting a PHYTEC phyCORE SOM to an applicaiton.

On top of these standard manuals and guides, PHYTEC will also provide Product Change Notifications, Application Notes, and Technical Notes. These will be done on a case by case basis. Most of the documentation can be found in the applicable download page of our products.

Introduction

Hardware Overview

The phyBOARD‑Nunki i.MX 6 for phyCORE-i.MX 6 modules is a low-cost, feature-rich software development platform supporting the NXP® Semiconductor i.MX 6 microcontroller. Moreover, due to the numerous standard interfaces, the phyBOARD‑Nunki i.MX 6 can serve as the foundation for any application. At the core of the phyBOARD‑Nunki is the PCM-058/phyCORE-i.MX 6 System On Module (SOM), containing the processor, DRAM, NAND Flash, power regulation, supervision, transceivers, and other core functions required to support the i.MX 6 processor. Surrounding the SOM is the PBA‑C‑11/ phyBOARD‑Nunki carrier board adding power input, buttons, connectors, signal breakout, and Ethernet connectivity among other peripherals.

Adding the phyCORE-i.MX 6 SOM into your own design is as simple as ordering the connectored version (PCM-058) and making use of our phyCORE Carrier Board reference schematics.

phyBOARD-Nunki i.MX 6 Features

The phyBOARD‑Nunki i.MX 6 supports the following features :

- Developed in accordance with PHYTEC's new SBCplus concept (Preface)

- PHYTEC’s phyCORE-i.MX 6 SOM featuring an ARM Cortex-A9 single, dual, or quad core operating at speeds up to 1.2 GHz

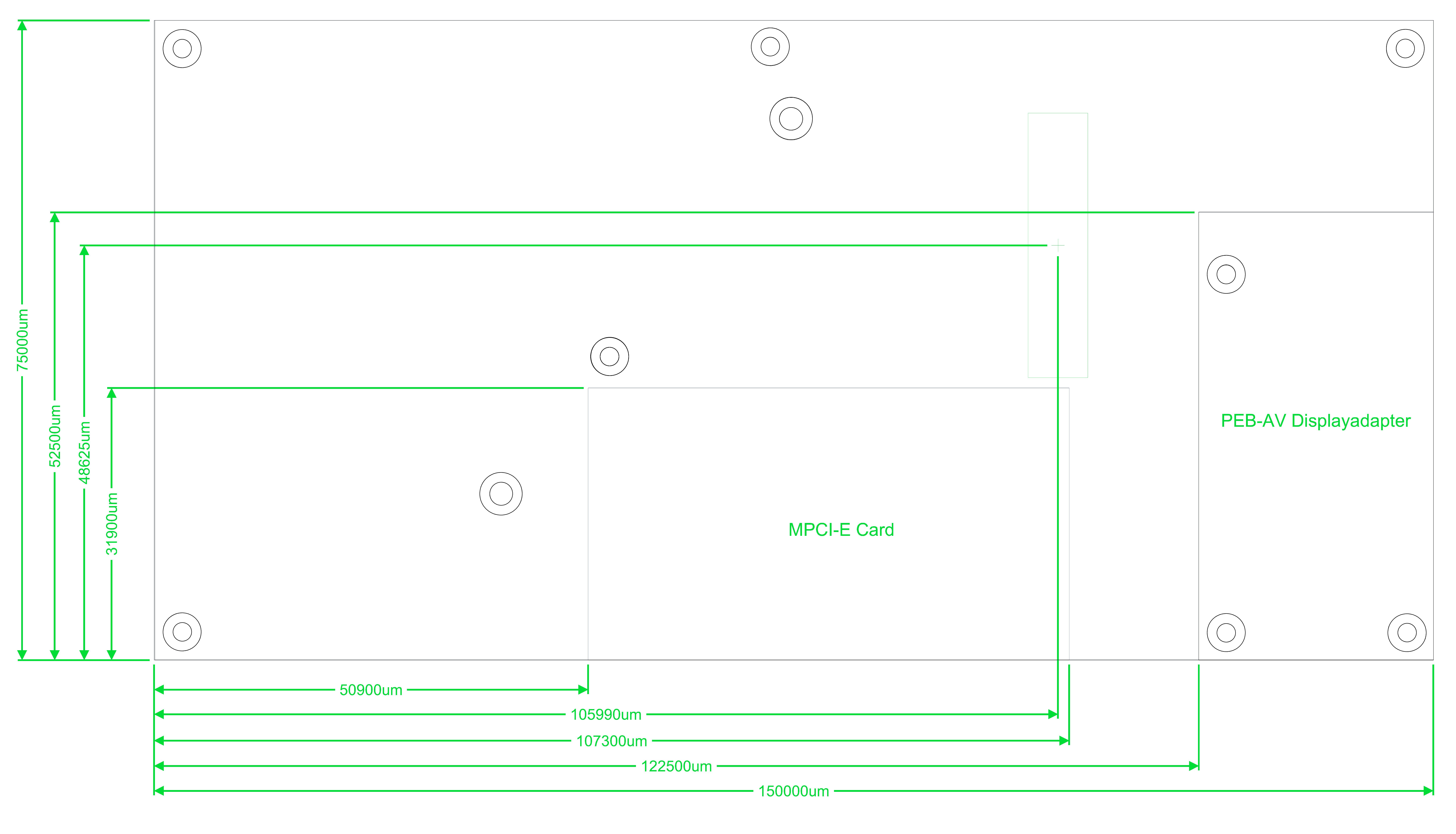

- 150 mm × 75 mm form factor

- Boot from SD card or NAND Flash

- Two different power supply options (10.8 V to 26.4 V) via Barrel Connector (2.0 mm/6.3 mm) or 2 pole Molex Micro-Fit 3.0™ Right Angle Header (optional)

- One RJ45 jack for 10/100/1000 Mbps Ethernet

- One USB host interface brought out to an upright USB Standard-A connector

- One USB OTG interface available at an USB Micro-AB connector

- One Secure Digital / Multi Media Memory Card interface brought out to a Micro-SD connector (found on the bottom of the phyBOARD)

- CAN interface at 2×5 pin header 2.54 mm

- Two camera interfaces, each compatible with the PHYTEC phyCAM‑P and phyCAM‑S+ standard

- One camera interface, compatible with the phyCAM-M standard (CSI-2 MIPI)

- Serial Debug Interface (UART2 over USB) at an USB Micro-AB connector

- Audio/Video (A/V) connectors (parallel, resistive touch screen, I2S, I²C, additional control signals)

- LVDS Display Connector (4 Lanes + Clock, USB, I²C, UART, power supply)

- Display Power Connector (VCC_IN, +5 V, +3V3, PWM, Display Enable)

- HDMI Connector

- Mini-PCIe Connector

- SATA Connector

- Reset-Button

- Multicolor-LED

- Expansion connector with different interfaces e.g. JTAG

- Additional gold cap buffered RTC

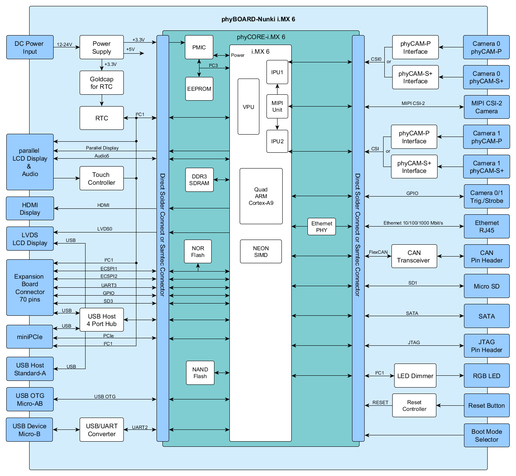

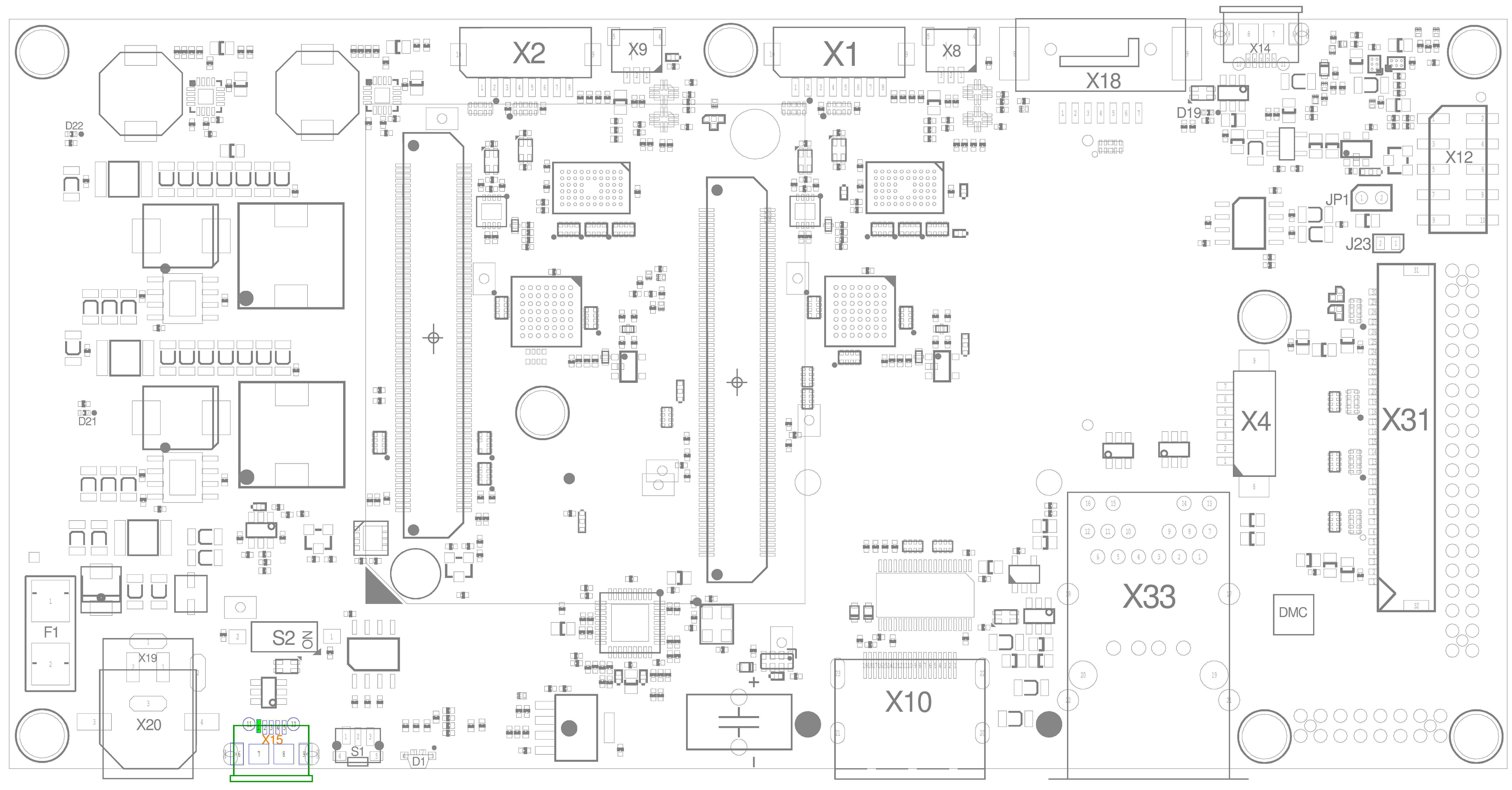

phyBOARD-Nunki i.MX 6 Block Diagram

phyBOARD-Nunki i.MX 6 Block Diagram

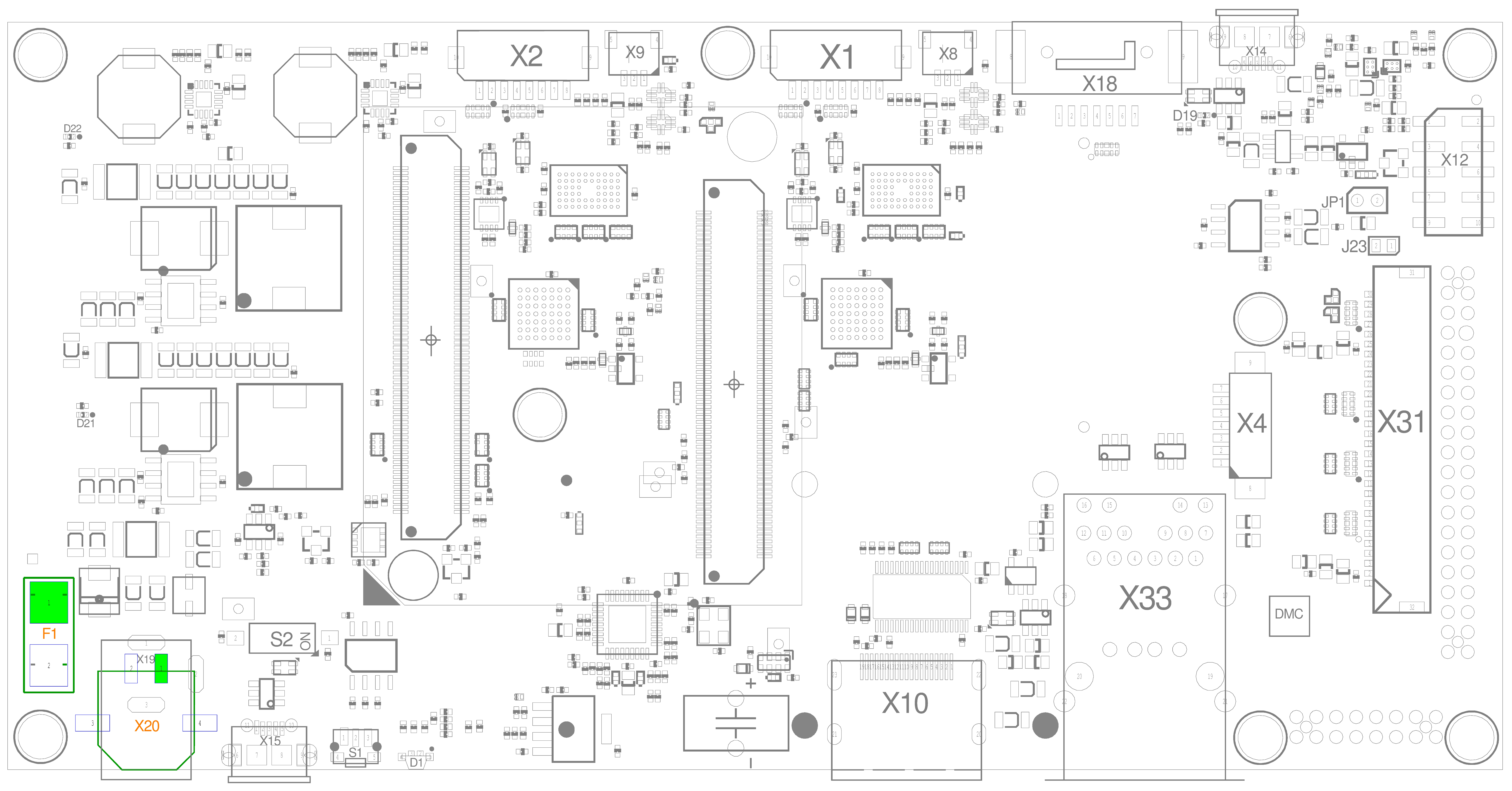

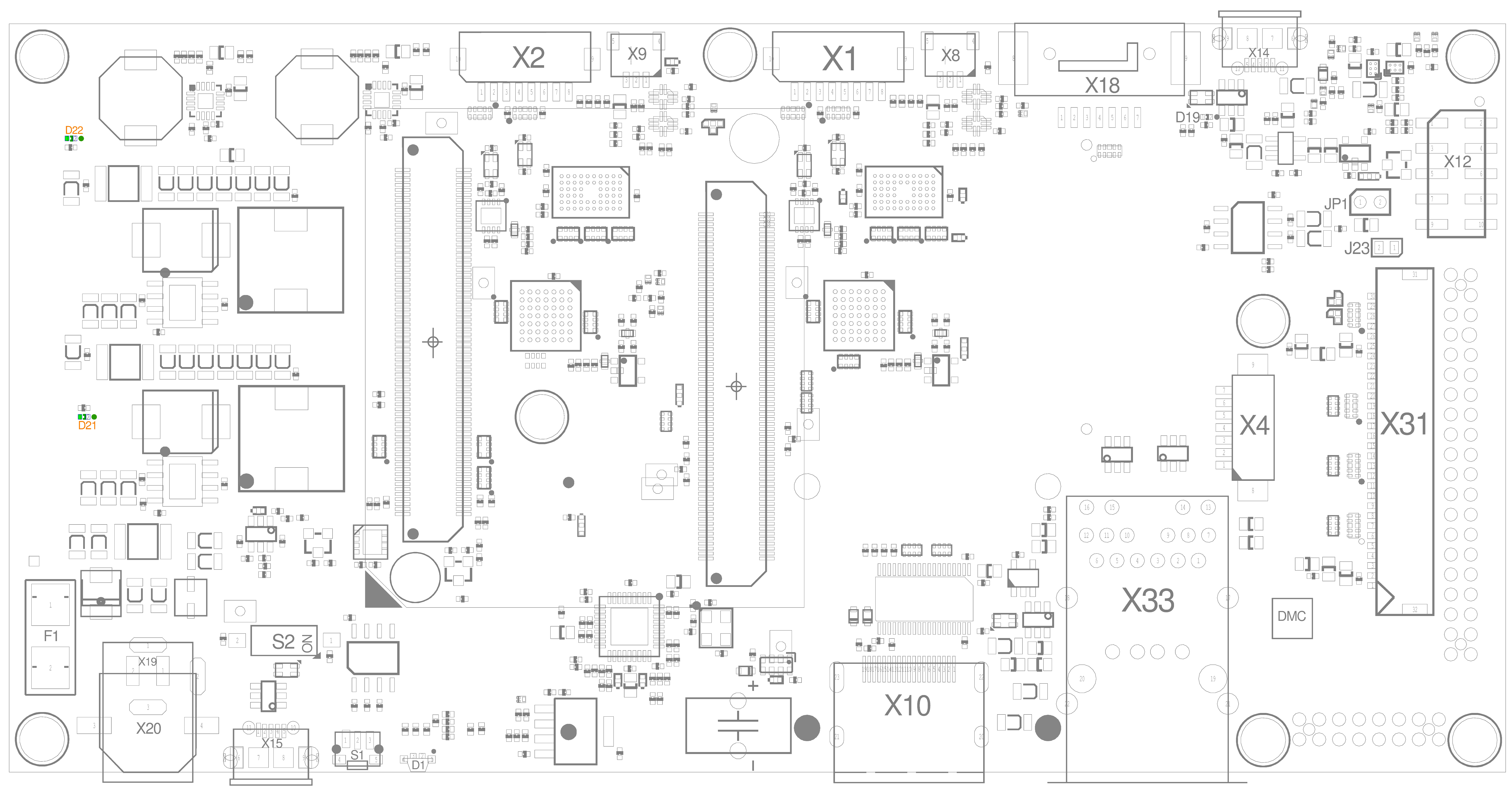

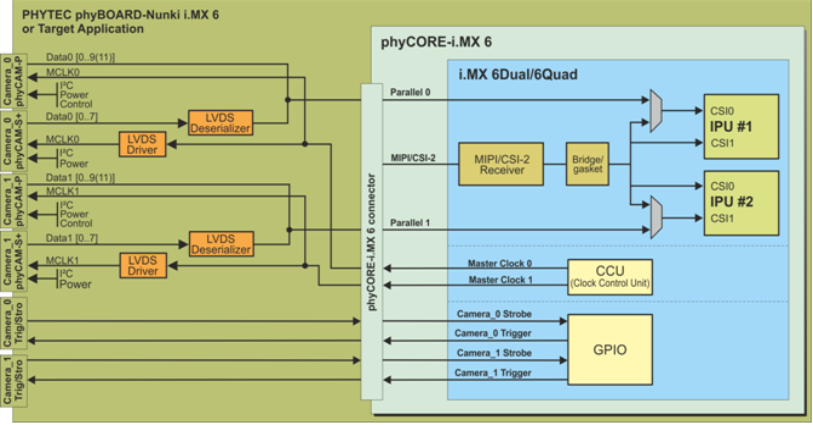

phyBOARD-Nunki Components

Tip

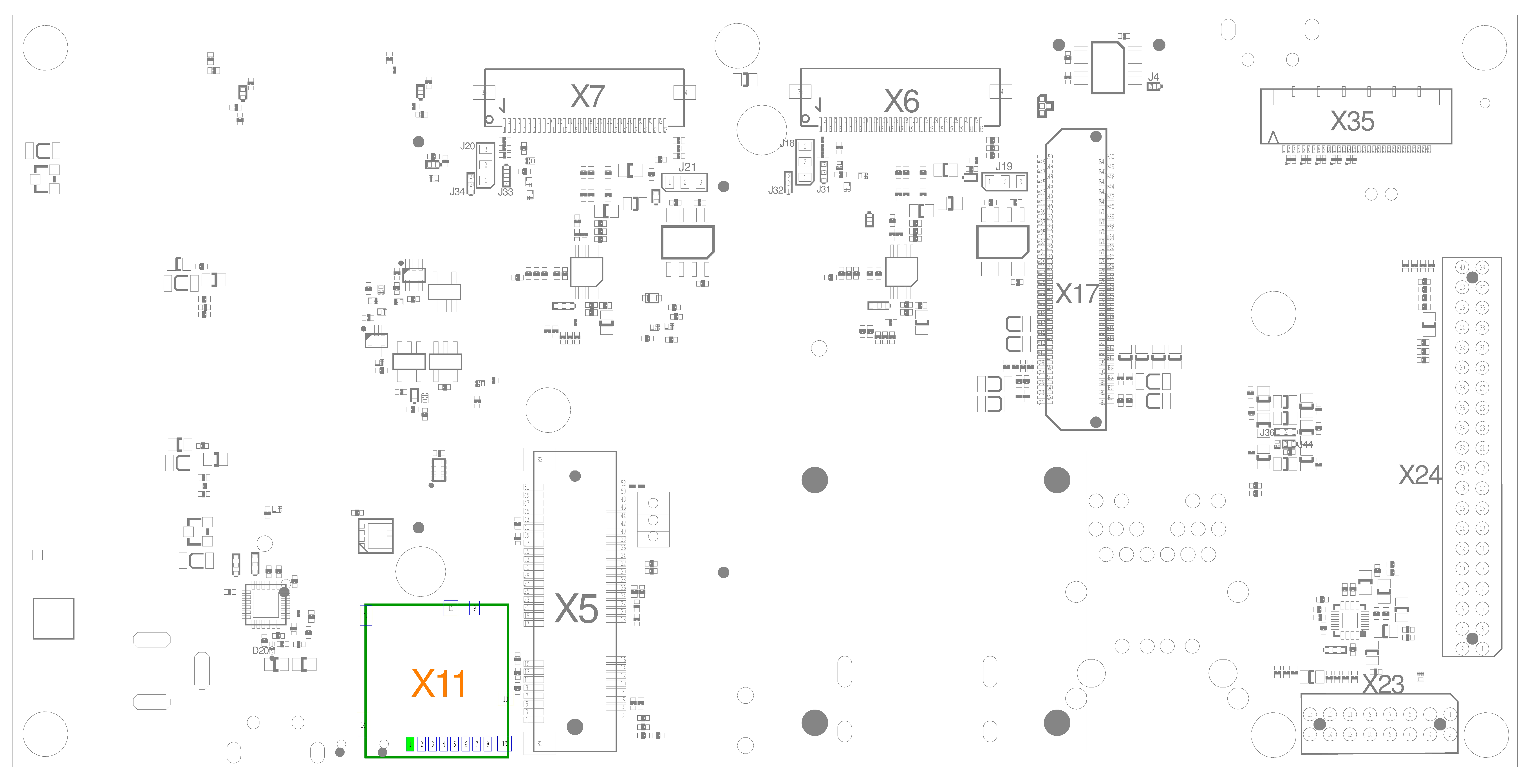

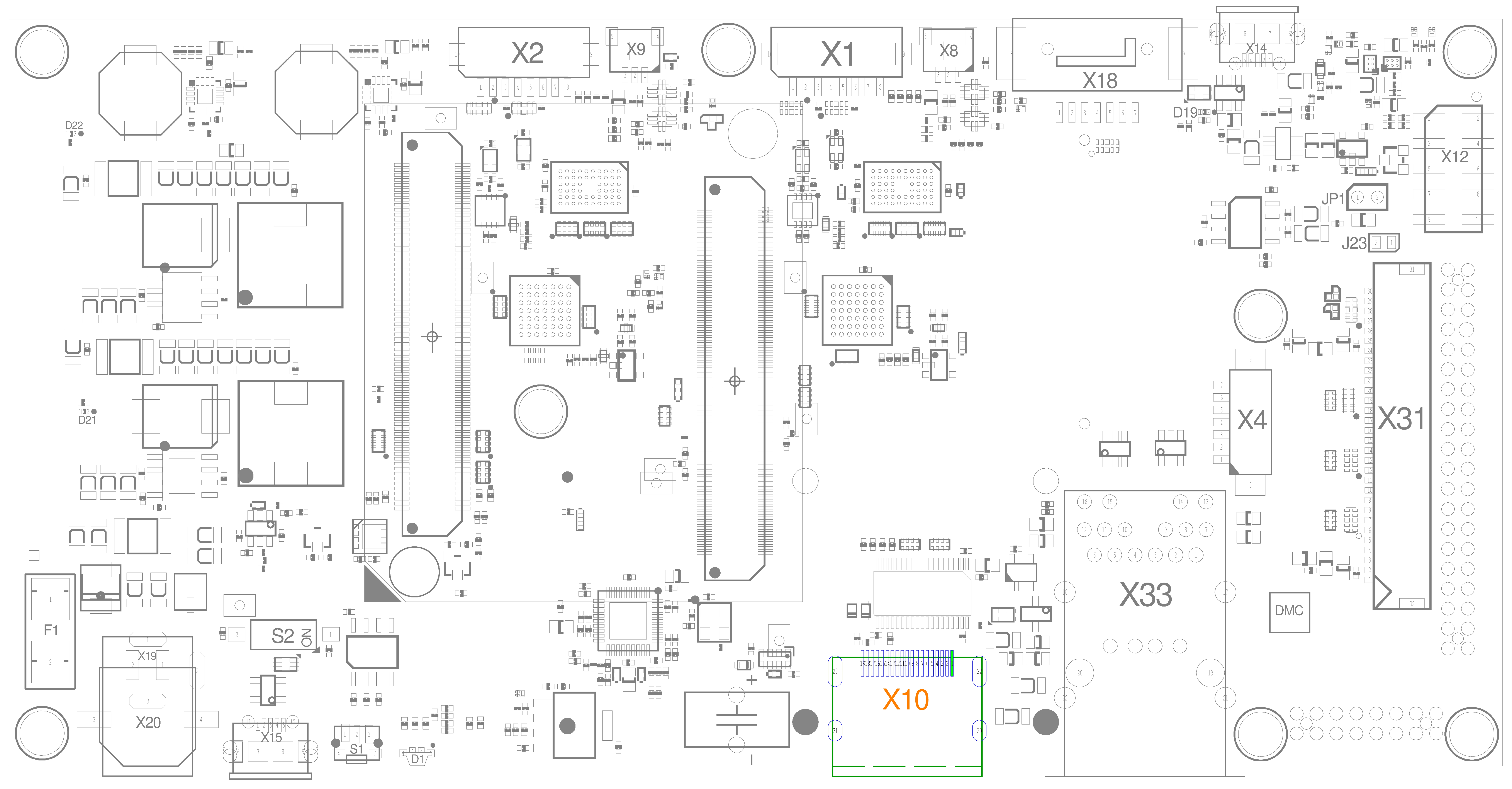

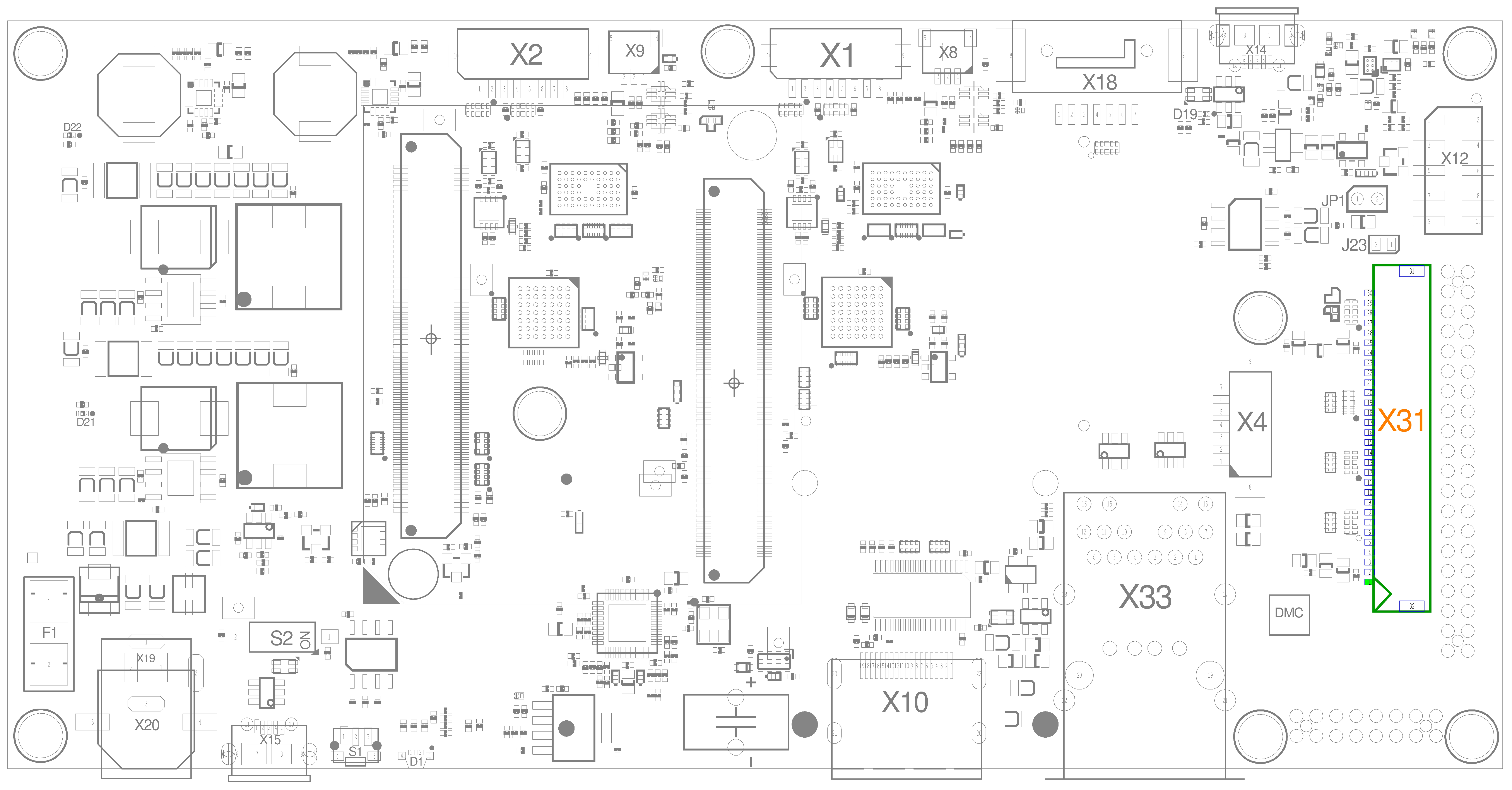

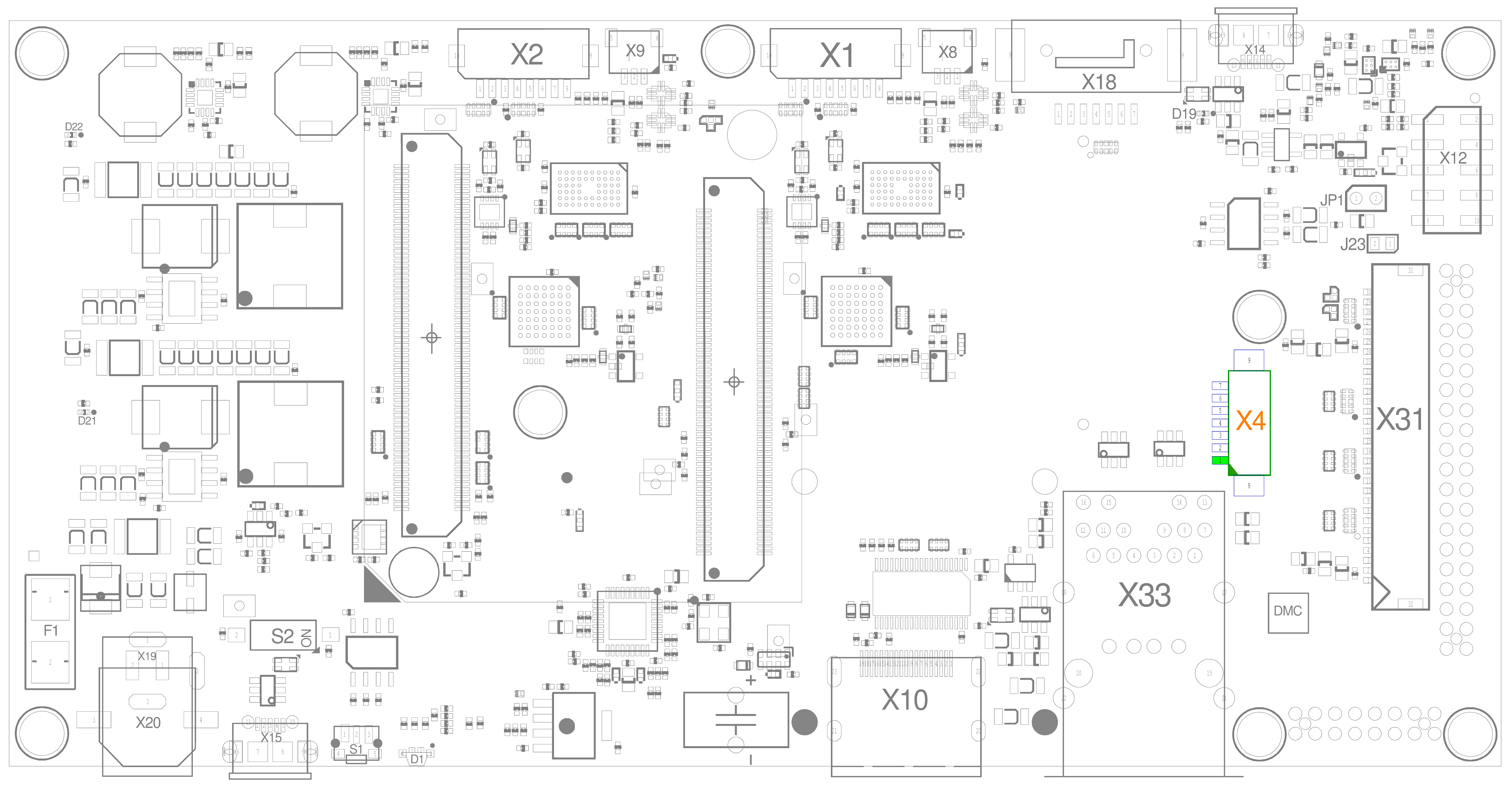

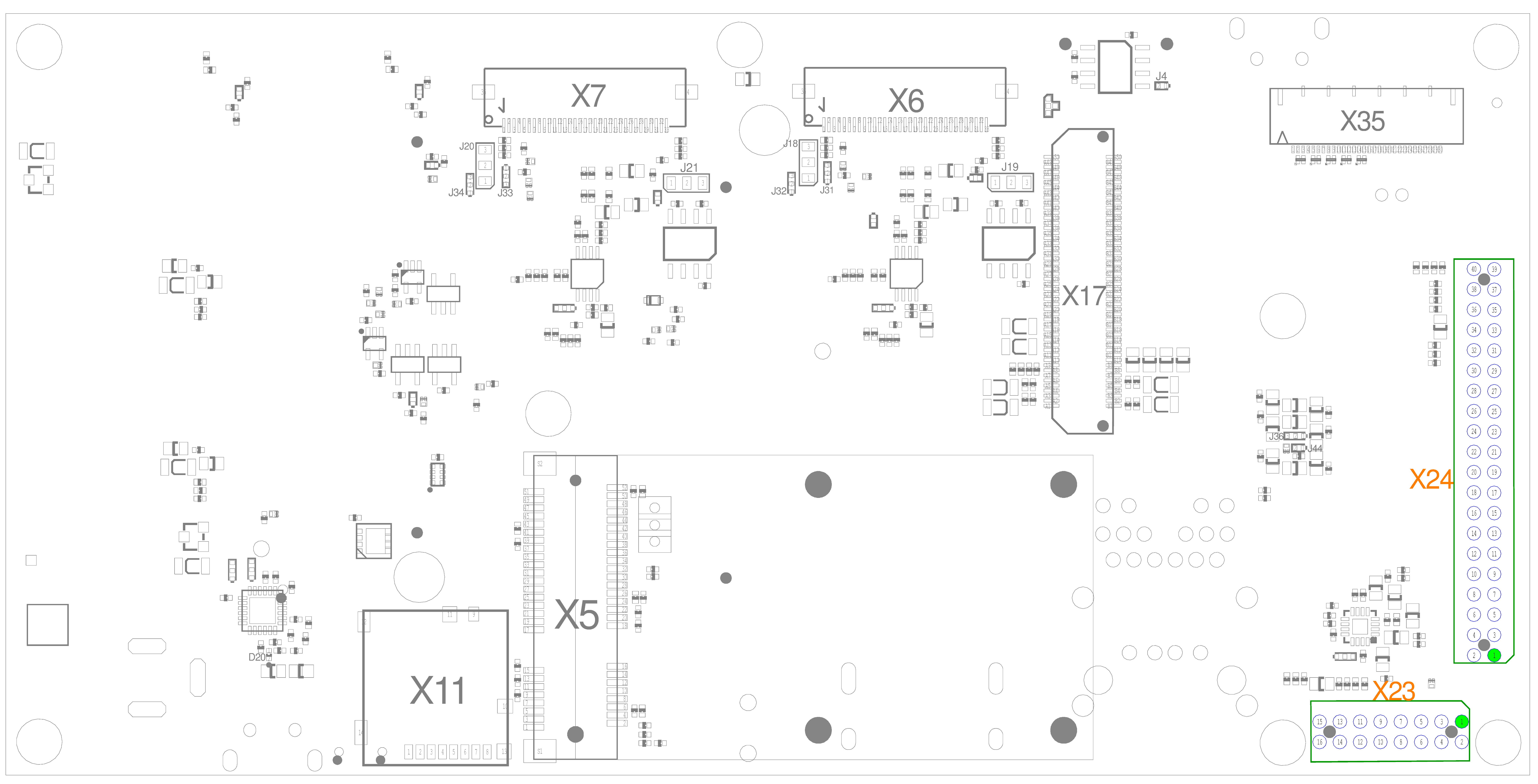

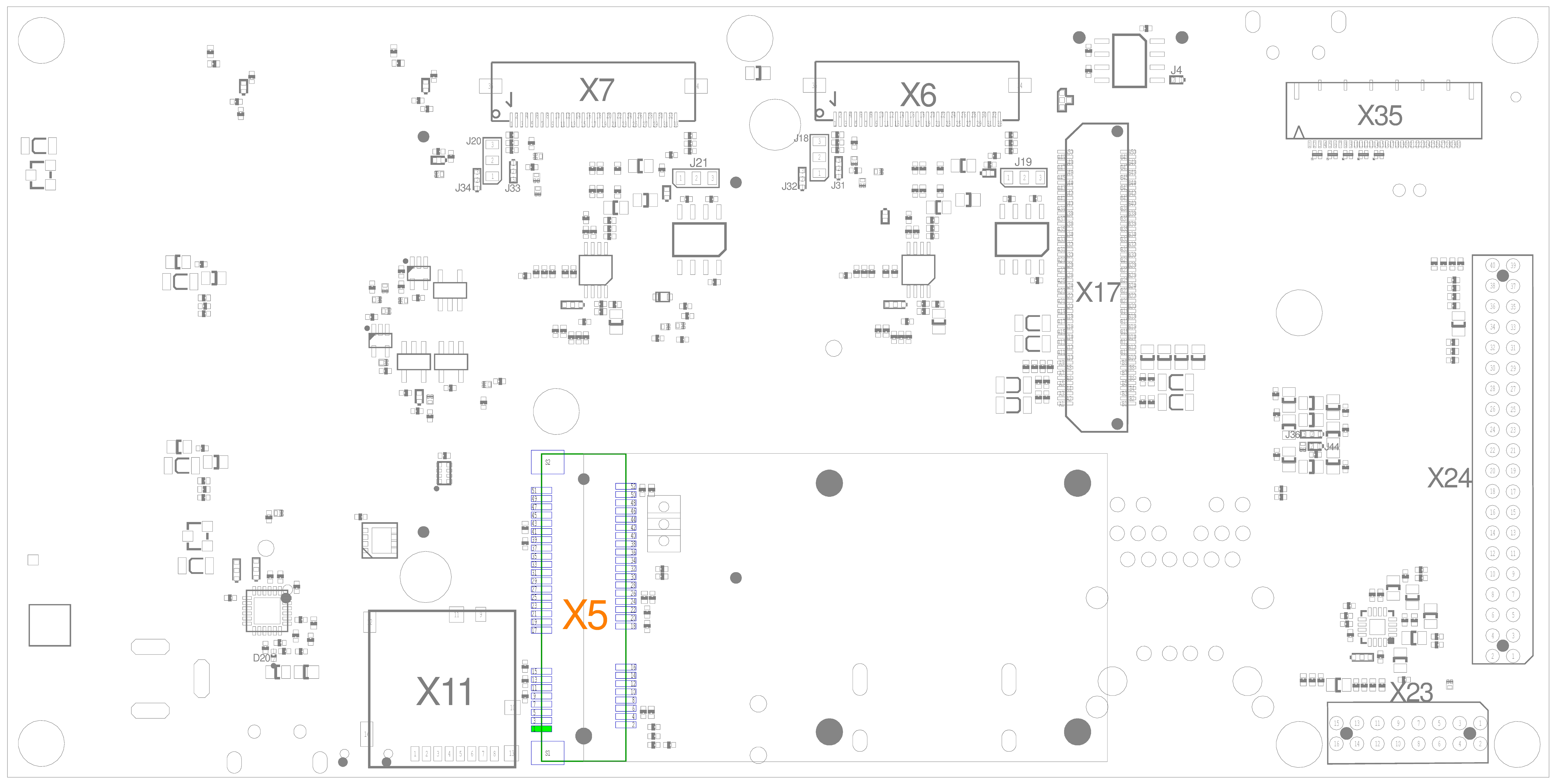

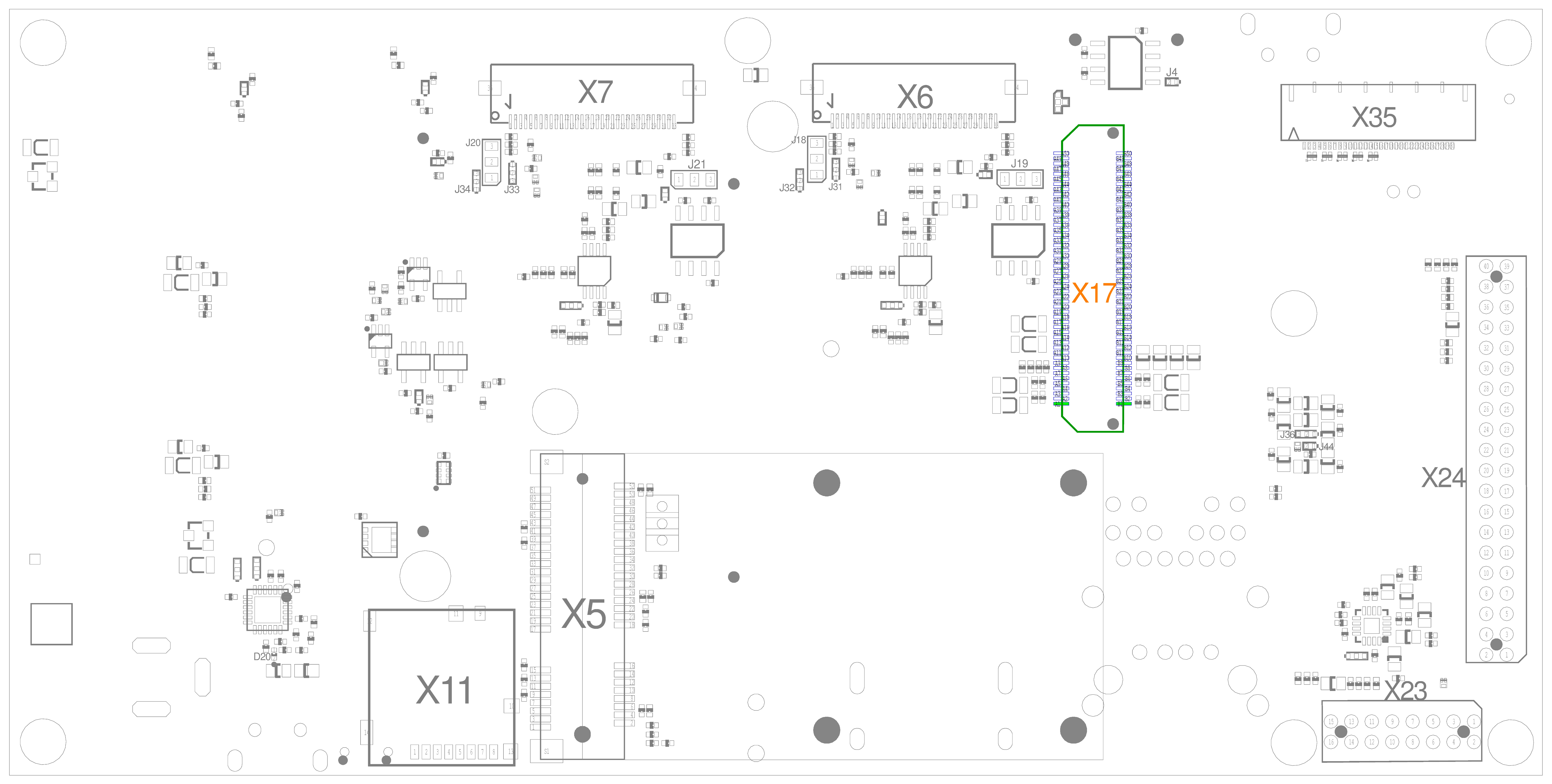

For easy reference, Pin 1 for each component has been highlighted.

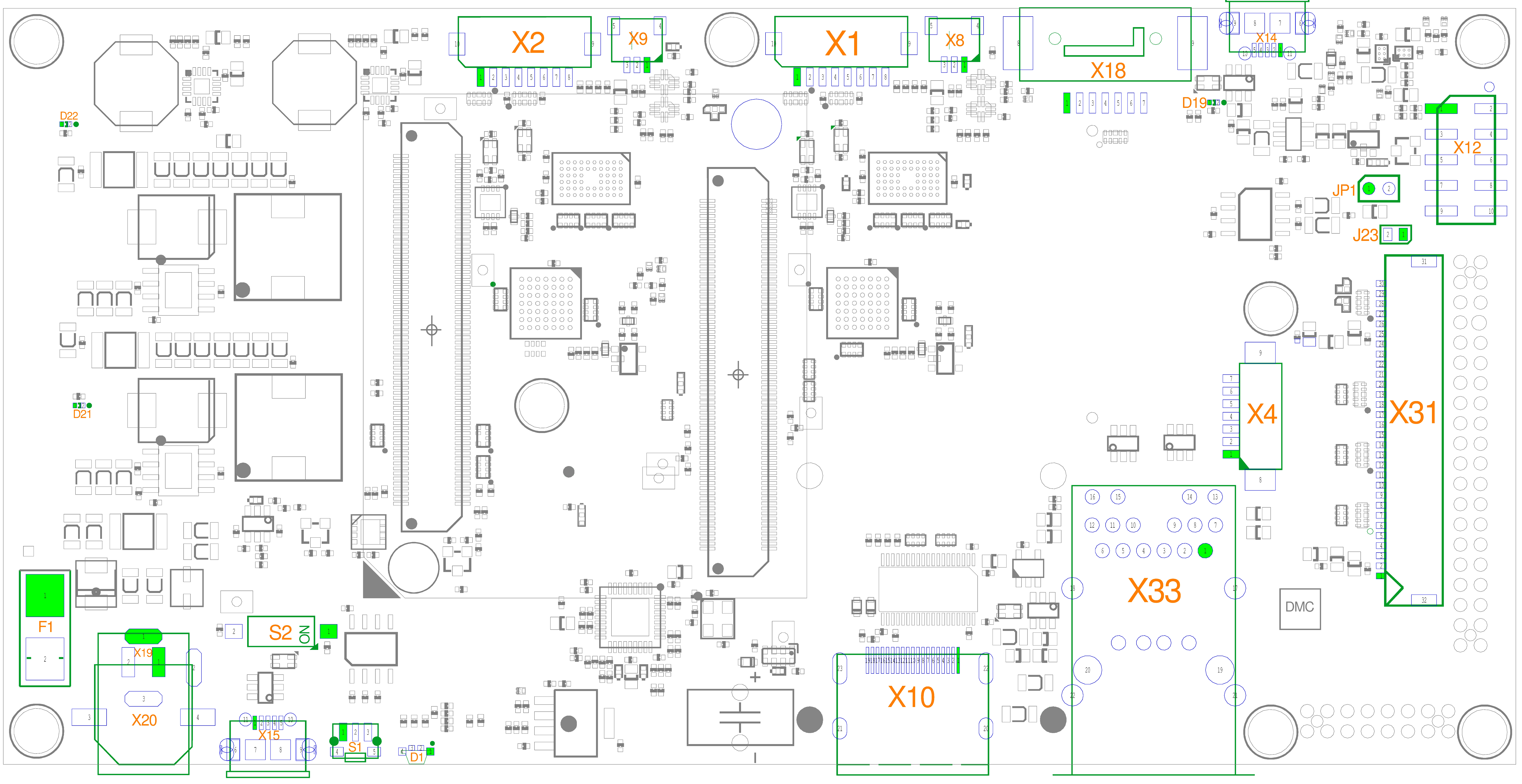

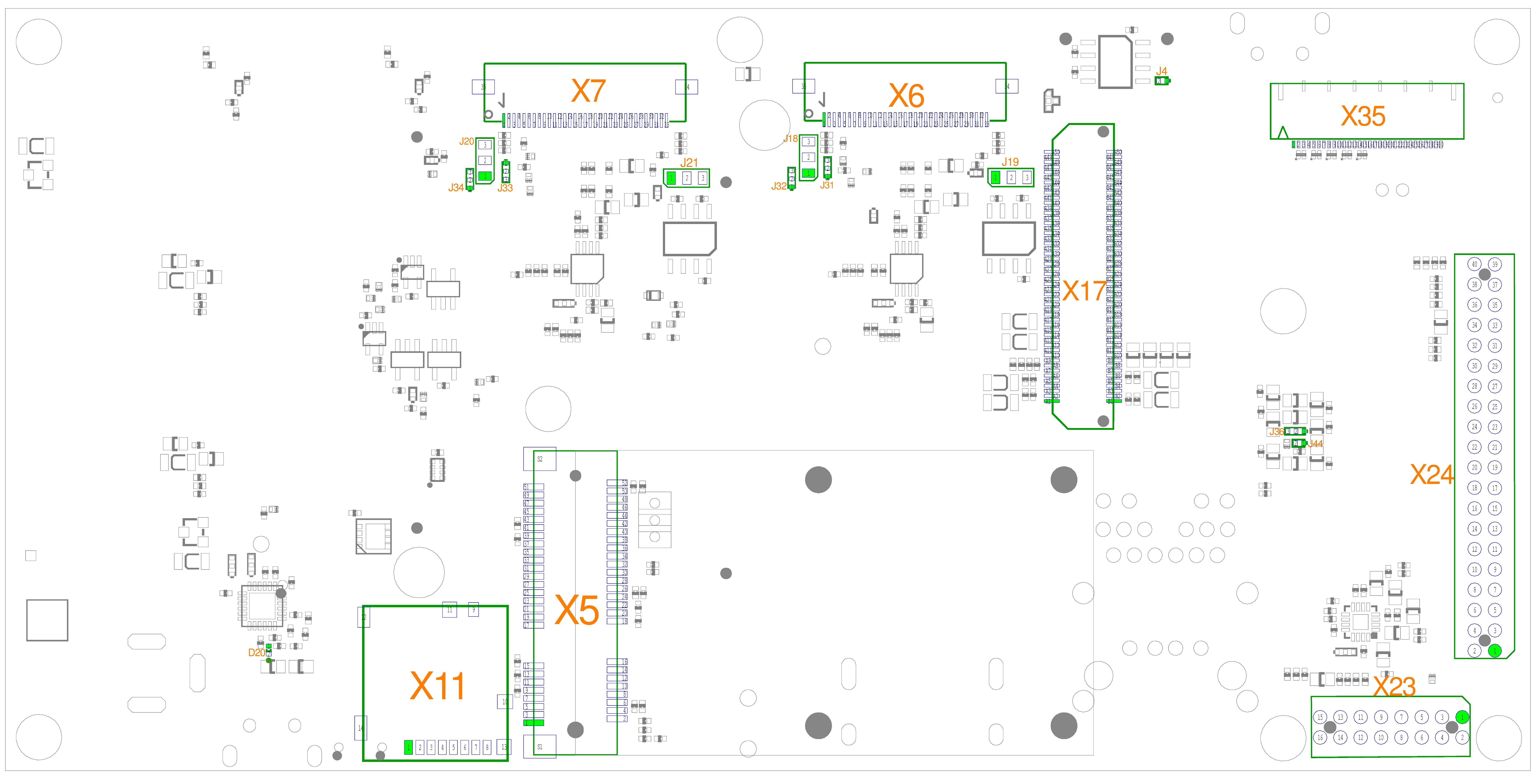

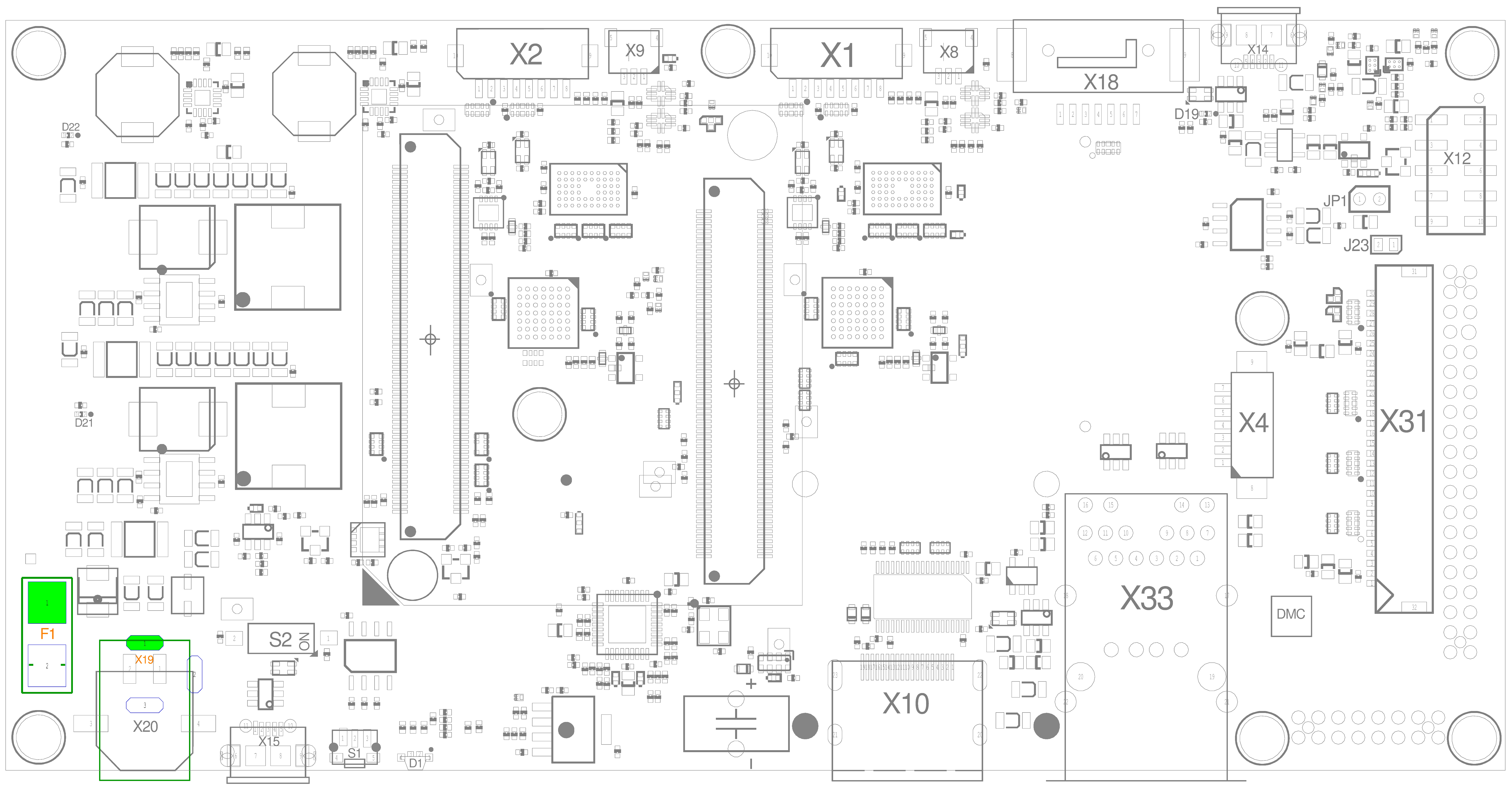

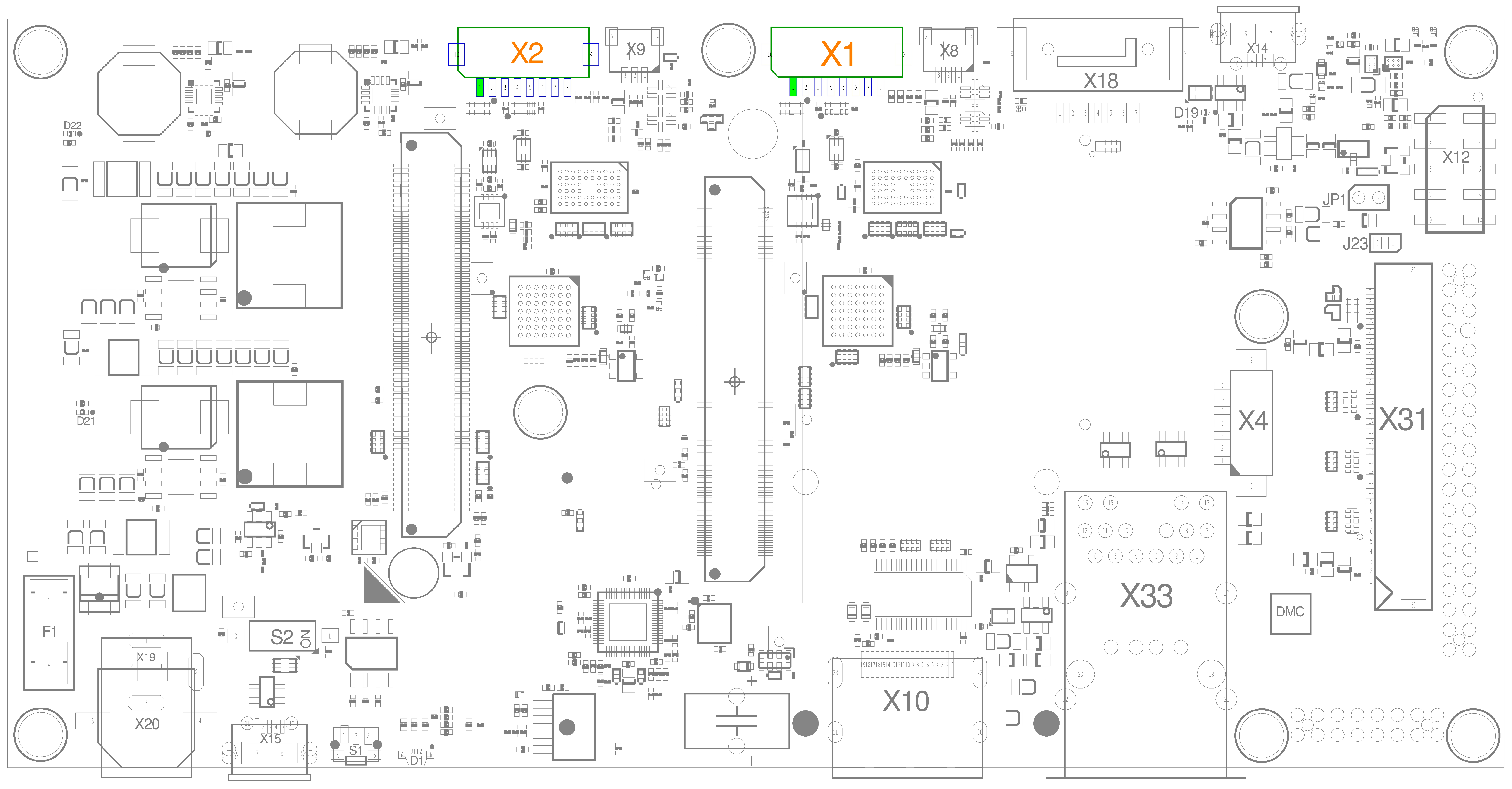

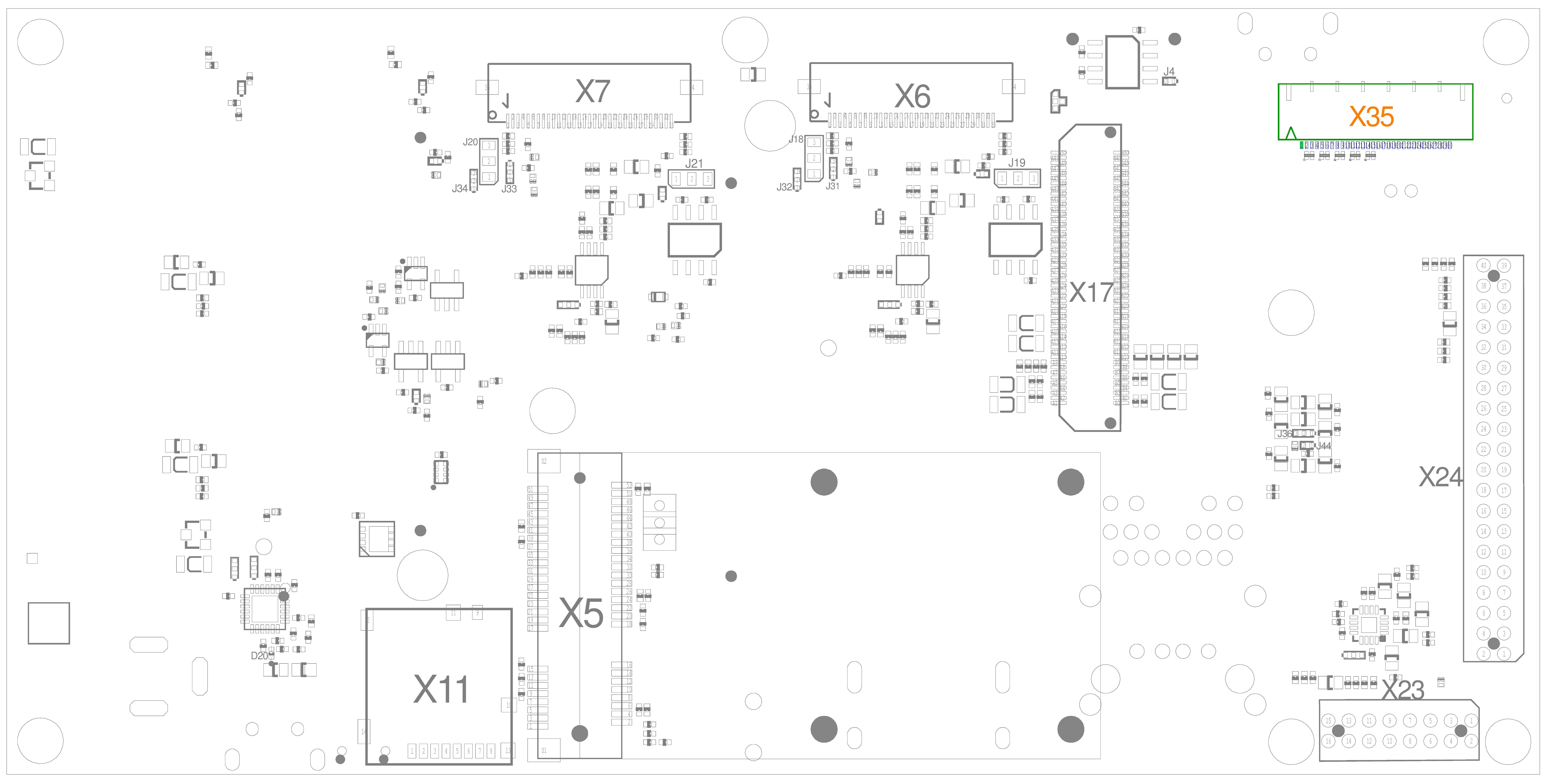

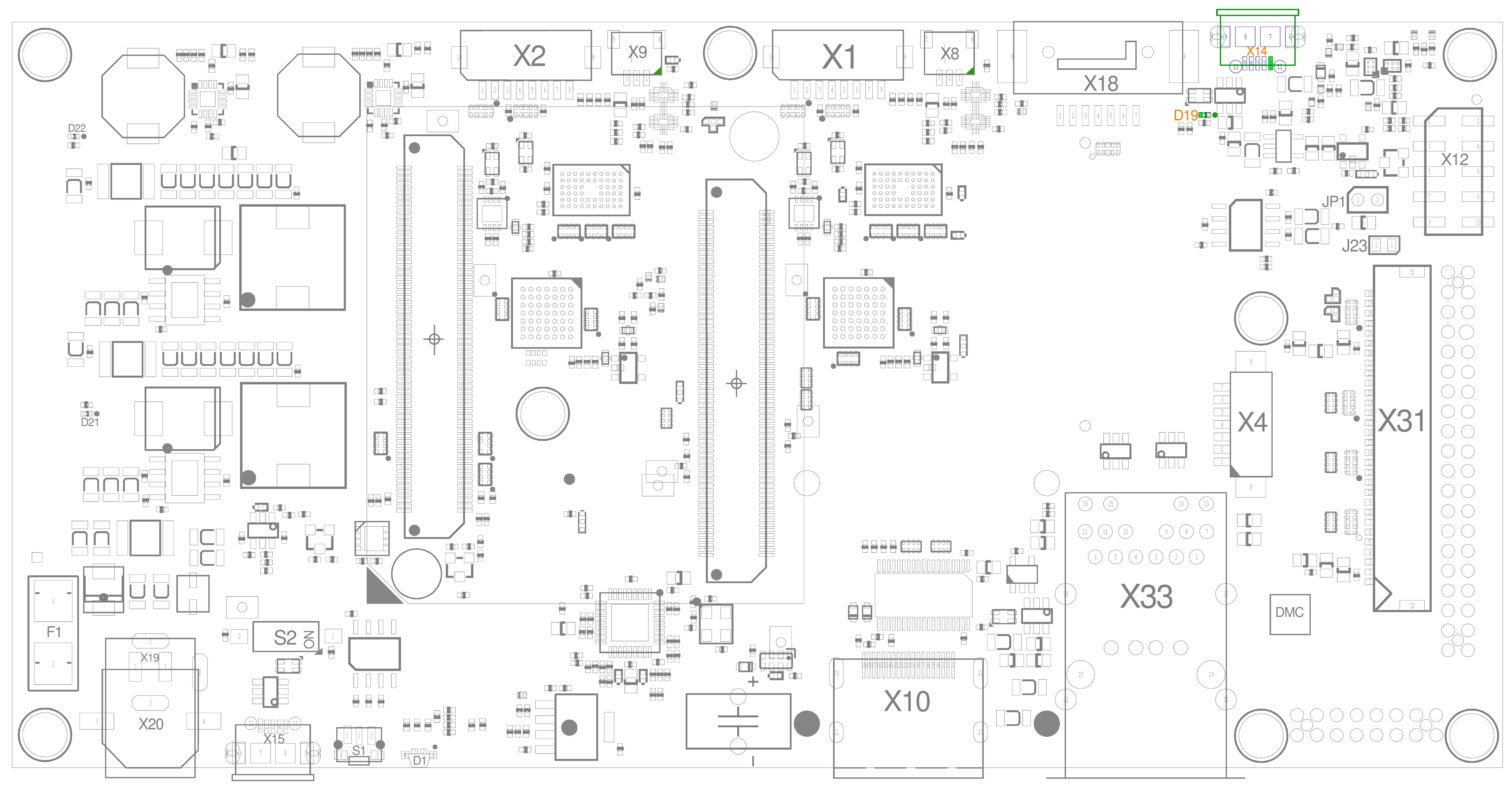

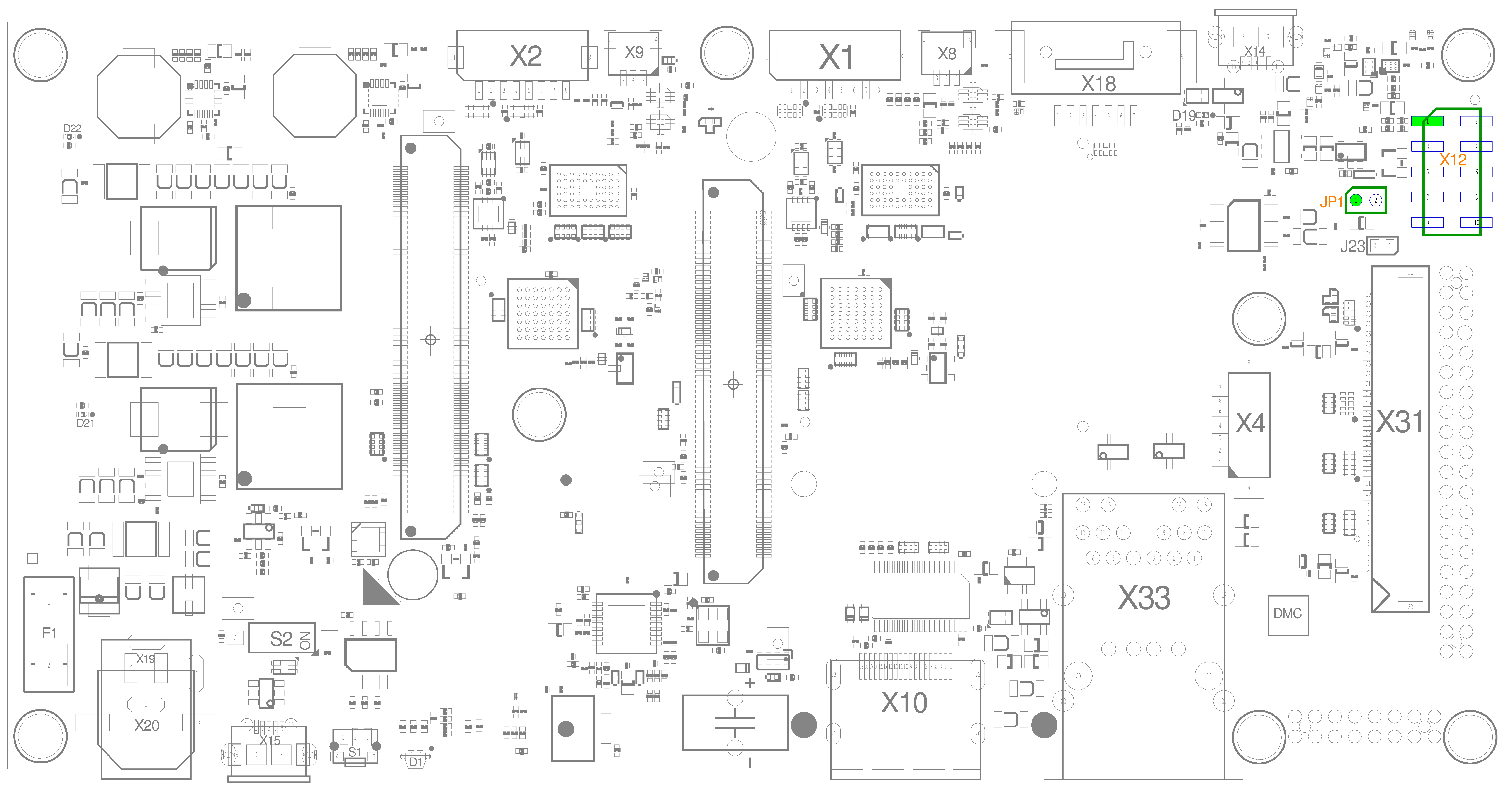

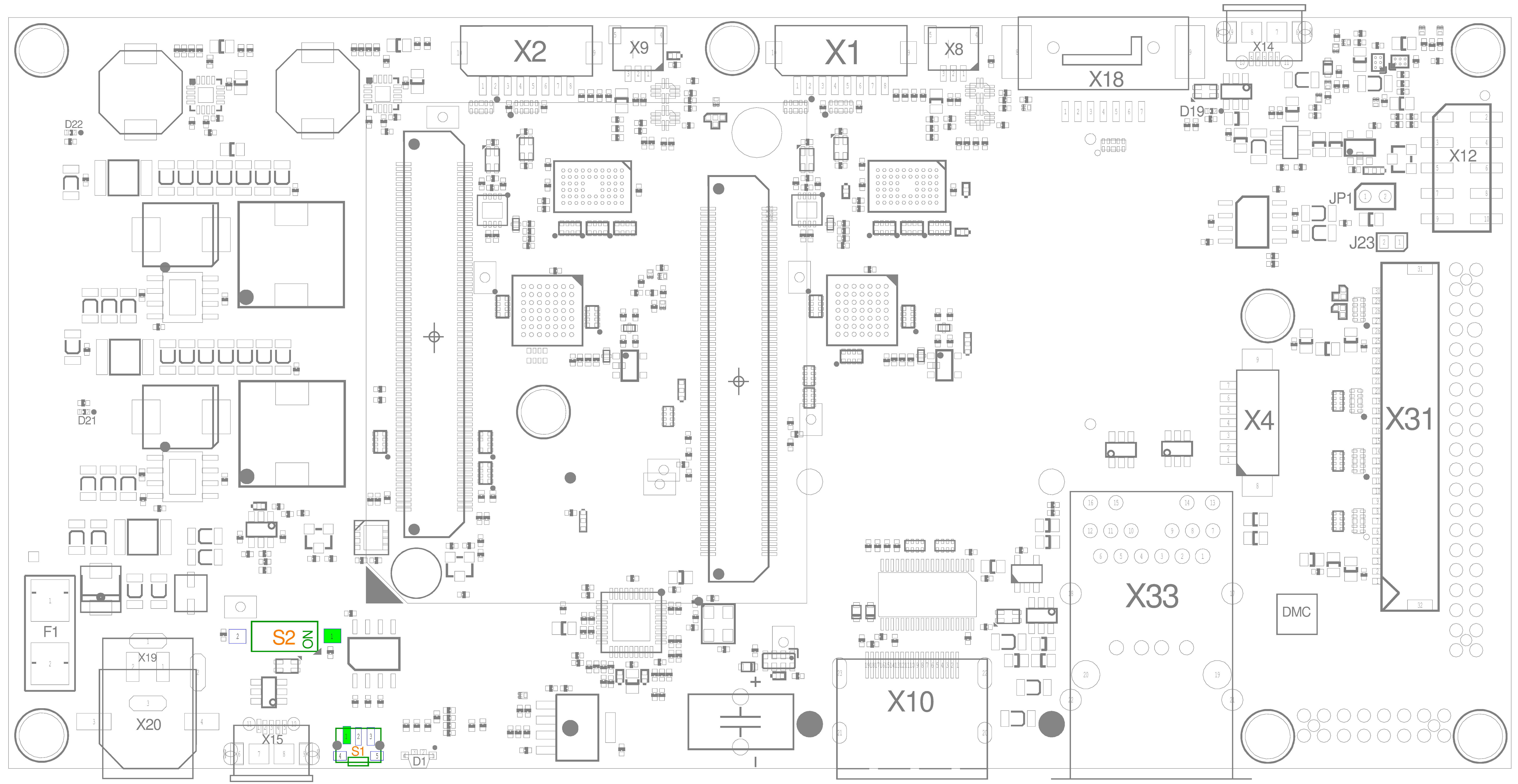

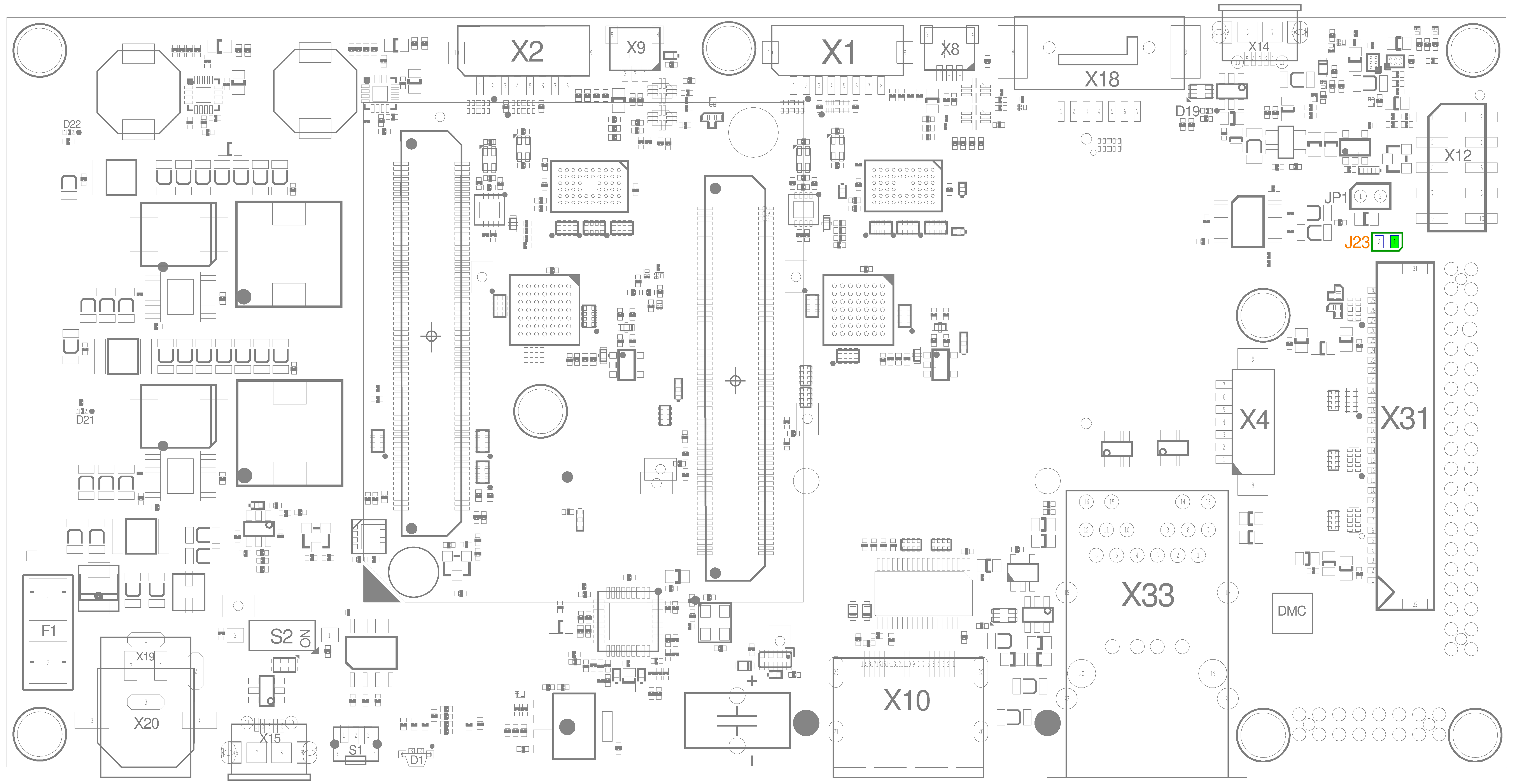

phyBOARD-Nunki i.MX 6 Component Placement

phyBOARD-Nunki i.MX 6 Component Placement (Top)

phyBOARD-Nunki i.MX 6 Component Placement (Bottom)

phyBOARD-Nunki Features

The phyBOARD‑Nunki is depicted in phyBOARD-Nunki i.MX 6 Component Placement (Top)andphyBOARD-Nunki i.MX 6 Component Placement (Bottom). It features many different interfaces and is equipped with the components listed in the section . For a more detailed description of each peripheral refer to the appropriate chapter listed in the applicable table.

Connectors and Pin Headers

The table below lists all available connectors on the phyBOARD-Nunki.

Reference Designator | Description | Section |

X1 | CSI0 phyCAM‑S+ Connector | phyCAM-S+ (LVDS) |

X2 | CSI1 phyCAM‑S+ Connector | |

X4 | Display Power Connector | Display Power |

X5 | Mini PCIe Connector | Mini PCIe |

X6 | CSI0 phyCAM‑P Connector | phyCAM-P (Parallel) |

X7 | CSI1 phyCAM‑P Connector | |

X8 | CSI0 phyCAM Trigger/Strobe Connector | Trigger- / Strobe Connector |

X9 | CSI1 phyCAM Trigger/Strobe Connector | |

X10 | HDMI Connector | HDMI |

X11 | µSD-Card Slot | Secure Digital / MultiMedia Card |

X12 | CAN Connector | CAN |

X14 | USB OTG Connector | USB OTG |

X15 | USB Debug Connector (UART2 to USB) | UART |

X17 | Expansion Connector | UART / Expansion |

X18 | SATA Connector | SATA |

X19 | Power Connector +24 V (10.8 V – 26.4 V) | Barrel Connector |

X20 | Power Connector +24 V (10.8 V – 26.4 V) | Molex Micro-Fit |

X23 | Audio/res. Touch Connector | Audio/Video |

X24 | Display Connector (Parallel Display) | |

X31 | Universal Display Interface Connector (LVDS Display) | LVDS Display |

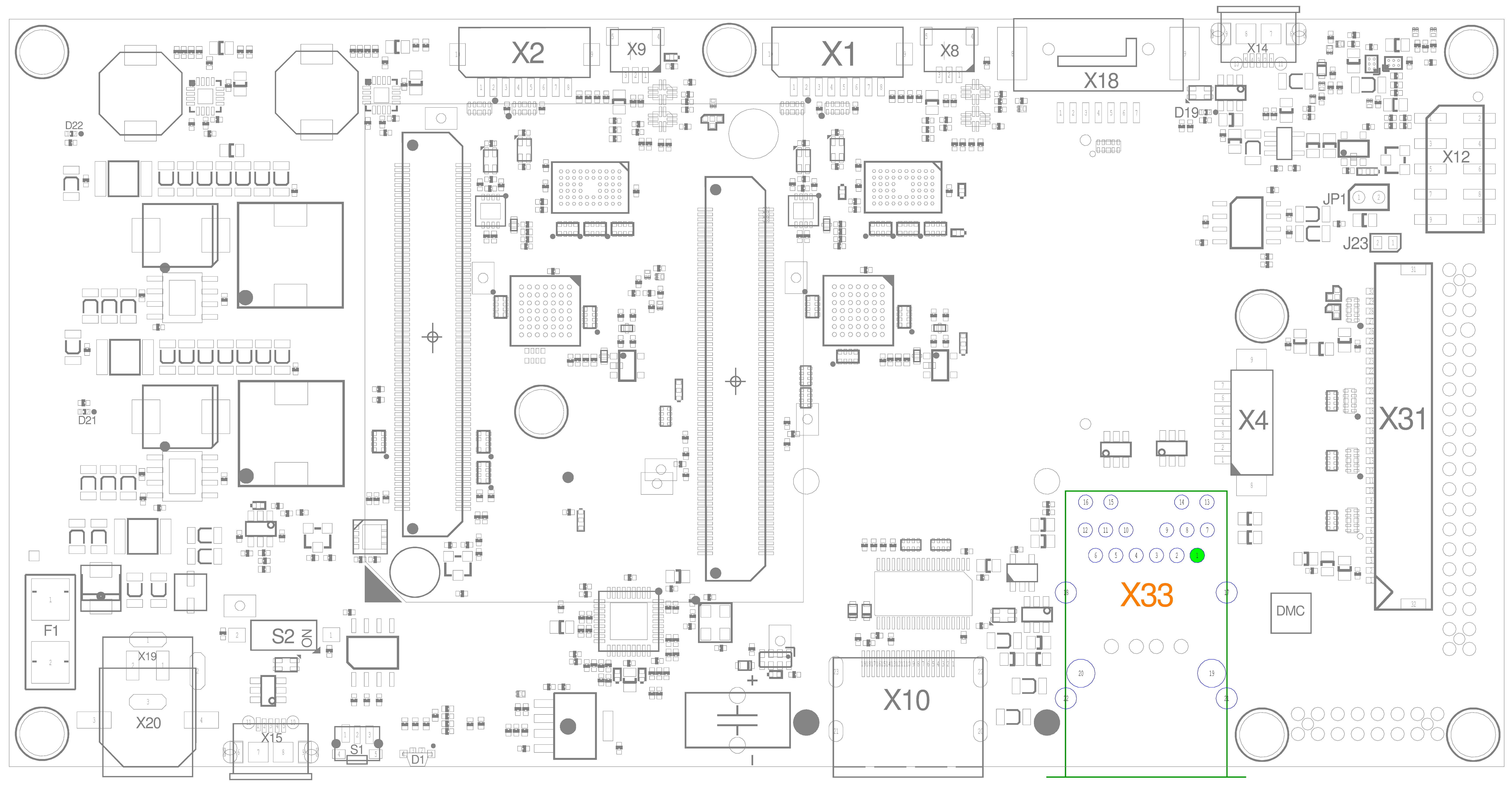

| X33 | 10/100/1000 Ethernet, USB Host Connector | Ethernet / USB Host |

| X35 | MIPI CSI-2 phyCAM-M Connector | phyCAM-M (MIPI CSI‑2) |

phyBOARD-Nunki i.MX 6 Connectors and Pin Headers

Warning

Ensure that all module connections do not exceed their expressed maximum voltage or current. Maximum signal input values are indicated in the corresponding controller User's Manual/Data Sheets. As damage from improper connections varies according to use and application, it is the user‘s responsibility to take appropriate safety measures to ensure that the module connections are protected from overloading through connected peripherals.

LEDs

The phyBOARD‑Nunki i.MX 6 is populated with four LEDs to indicate the status of the USB VBUS voltages and the power supply voltage. There is also one user programmable multicolor LED. phyBOARD-Nunki i.MX 6 Component Placement (Top) shows the location of the LEDs. Their functions are listed below.

LED | Color | Description | Section |

D1 | RGB | Multicolor User-LED | Multicolor LED |

D19 | Green | Indicator for USB OTG voltage at connector X14 | USB OTG |

D20 | Green | Indicator for USB Debug voltage at connector X15 | UART |

D21 | Green | Indicator for +3.3 V voltage for phyCORE | Power Supply LEDs |

D22 | Green | Indicator for +5 V voltage |

phyBOARD-Nunki i.MX 6 LEDs

Buttons and Switches

The phyBOARD-Nunki i.MX 6 is populated with a push button to reset the phyBOARD and another DIP-Switch to select the boot source of the phyCORE i.MX 6. phyBOARD-Nunki i.MX 6 Component Placement (Top) shows the location of S1 and S2. Their functions are listed below.

Switch | Description | Section |

S1 | Reset Button | System Reset |

S2 | Boot Source Selection | Boot Mode |

phyBOARD-Nunki i.MX 6 Buttons and Switches

Jumpers

The phyBOARD-Nunki i.MX 6 comes pre-configured with one removable jumper (JP) and several solder jumpers (J). The jumpers allow for flexible configuration of a limited number of features for user development purposes.

Warning

Due to the small footprint of the solder jumpers (J), PHYTEC does not recommend manual jumper modifications. This may also render the warranty invalid. Only the rempvable jumper (JP) is described in this section. Contact our sales team if you need jumper configurations different from the default configuration.

phyBOARD-Nunki i.MX 6 Component Placement (Top) shows the location of JP1. The function is listed below.

Jumper | Description | Section |

JP1 | CAN Termination Selection | CAN |

phyBOARD-Nunki i.MX 6 Jumper

phyBOARD-Nunki i.MX 6 Component Detail

This section provides a more detailed look at the phyBOARD‑Nunki components. Each subsection details a particular connector/interface and associated jumpers for configuring that interface.

Power Connectors (X19 and X20)

The phyBOARD‑Nunki i.MX 6 is available with two different power supply connectors. Depending on your order, you will find one of the following connectors on your SBC:

- a Barrel Connector with a diameter of 2.0 mm/6.3 mm

- a 2 pole Molex Micro-Fit 3.0™ Right Angle Header (optional)

The required current load capacity for all power supply solutions depends on the specific configuration of the phyCORE mounted on the phyBOARD-Nunki i.MX 6, the particular interfaces enabled while executing software, as well as whether an optional expansion board is connected to the carrier board.

A 2 A Fuse (Fast-Acting Fuse) is used to cut off the external power supply from the phyBOARD in case of an electrical error.

Barrel Connector (X19)

Barrel Connector (X19) with Polarity

Barrel Connector (X19)

The permissible input voltage is +10.8 V to +26.4 V DC. The phyBOARD‑Nunki i.MX 6 is designed for a nominal voltage of +24 V ± 10 %. The power supply voltage +24V_IN is routed to several plug connectors on the board as +24V_IN_FILTER. An external power supply with a minimum supply of 2 A is recommended to supply the board via the 2-pole base strip.

Pin assignment of the Barrel Connector at X19:

Interface Pin | Signal | Description |

1 | +24V_IN | +24 V power supply in (+10.8 V to +26.4 V) |

2/3 | GND | Ground |

Pin Assignment of the Barrel Connector at X19

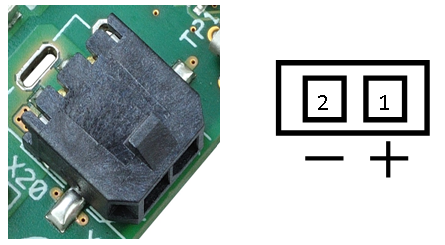

Molex Micro-Fit 3.0™ (X20)

Molex Micro 3.0TM Connector with Polarity

Molex Micro 3.0TM Connector (X20)

With a Molex Micro-Fit 3.0™, the phyBOARD can be supplied using a plug connector.

Use of the 2-pole connector has the following advantages:

- Lockable plug connection

- Flexible Design

- Secure against accidental disconnection or misconnection

- Ideal for product-specific power supply solutions

Pin assignment of the 2–pole Molex Micro-Fit 3.0™ Header at X20:

Pin | Signal | Description |

1 | +24V_IN | +24 V power supply in (+10.8 V to +26.4 V) |

2 | GND | Ground |

Pin Assignment of the 2-pole Molex Micro-Fit 3.0™ Connector at X20

Power Supply LEDs (D21 and D22)

Power Supply LEDs (D21 and D22)

The green LED D21 on the middle left-hand side of the board indicates the presence of the +3.3 V supply voltage of the phyCORE module generated from the +24V_IN input voltage. The green LED D22 on the upper left-hand side of the board indicates the presence of the +5 V supply voltage of the phyBOARD peripherals generated from the +24V_IN input voltage.

Ethernet (X33)

Ethernet Connector (X33)

The Ethernet interfaces of the phyBOARD-Nunki i.MX 6 are accessible at RJ45 connector X33. X33 is located on the lower right side of the board.

Ethernet is directly brought out from the SOM's Ethernet interface. The Ethernet interface is configured as 10/100/1000Base-T network. The LEDs for LINK (green) and TRAFFIC (orange) are integrated into the connector. The Ethernet transceiver supports HP Auto-MDIX, eliminating the need for a direct connect LAN or a cross-over path cable. They detect the TX and RX pins of the connected device and automatically configure the PHY TX and RX pins accordingly.

MAC Address

In a computer network such as a local area network (LAN), the MAC (Media Access Control) address is a unique computer hardware number. For a connection to the Internet, a table is used to convert the assigned IP number to the hardware’s MAC address.

In order to guarantee that the MAC address is unique, all addresses are managed in a central location. PHYTEC has acquired a pool of MAC addresses. The MAC address of the phyBOARD‑Nunki i.MX 6 is located on the Data Matrix sticker attached to the module. This number is a 12-digit HEX value.

UART (X15, X17)

USB Debug Connector (X15)

The phyCORE‑i.MX 6 provides up to 2 high speed universal asynchronous interfaces. The phyBOARD UART2 (the standard console) is routed to X15 (micro USB AB) via an UART USB converter. X15 is located on the top of the board next to the power converter. The UART USB converter accesses the host PC as COM interface and can be used as such with a terminal program. The green LED D21 (Power LED (D21 and D22)) indicates that the UART USB converter is powered by the Host-PC.

Suitable connection cables:

PHYTEC Item no. | Length | Remarks |

WK345 | 1 m | USB A to micro USB B |

UART3 is routed to expansion connector X17. Further information on the UART X17 can be found in Expansion Connector.

Camera Connectors (X1, X2, X6-9, X35)

The phyBOARD‑Nunki i.MX 6 provides three types of camera interfaces (parallel, LVDS, and CSI‑2 MIPI).

On the target application, the camera interfaces can be used to connect:

- camera modules with phyCAM‑S+ interface (phyBOARD-Nunki i.MX 6 Component Placement (Top)andphyBOARD-Nunki i.MX 6 Component Placement (Bottom) and phyCAM-S+ (LVDS) Camera Interfaces (X1, X2))

- camera modules with phyCAM‑P interface (phyBOARD-Nunki i.MX 6 Component Placement (Top)andphyBOARD-Nunki i.MX 6 Component Placement (Bottom) and phyCAM-P (Parallel) Camera Interfaces (X6, X7))

- camera modules with phyCAM-M interface (phyBOARD-Nunki i.MX 6 Component Placement (Top)and phyCAM-M (MIPI CSI‑2) Camera Interface (X35))

- Two trigger/strobe headers, e.g. for synchronized image capturing, exposure control, etc. (phyBOARD-Nunki i.MX 6 Component Placement (Top)and Trigger / Strobe Connector (X8, X9))

Overview phyBOARD-Nunki i.MX 6 phyCAM Interface

On the phyBOARD‑Nunki i.MX 6, both parallel camera interfaces (CSI0 and CSI1) can be used simultaneously. Each CSI interface is upgraded with a complete phyCAM‑S+ and phyCAM‑P interface. Switching between phyCAM‑S+ and phyCAM‑P can be done in processor runtime using GPIOs.

Control Signals | CSI Interface | ||||

EIM_DA9 | EIM_DA8 | CSI0_DATA_EN | EIM_DA10 | Camera0 | Camera1 |

1 | 0 | 0 | 0 | Off | Off |

1 | 0 | 0 | 1 | Off | Off |

1 | 0 | 1 | 0 | Off | Off |

1 | 0 | 1 | 1 | Off | Off |

0 | 1 | 0 | 0 | phyCAM‑P | phyCAM‑P |

0 | 1 | 0 | 1 | phyCAM‑P | phyCAM‑S+ |

0 | 1 | 1 | 0 | phyCAM‑S+ | phyCAM‑P |

0 | 1 | 1 | 1 | phyCAM‑S+ | phyCAM‑S+ |

phyCAM Control Signals

The following sections give a basic overview on how to connect a camera using the different interface options. All figures show the phyBOARD‑Nunki i.MX 6 equipped with the i.MX 6 dual and quad core with two parallel interfaces. Additional information on connectable phyCAM modules can be found in the phyCAM manual (L-748e).

Tip

nCAMERA0_PWRDN and CAMERA1_PWRDN are not used in the default configuration. This means setting nCAMERA0_PWRDN or CAMERA1_PWRDN in the i.MX 6 has no effect on the hardware.

Do not connect a phyCAM-S+ and phyCAM-P camera module to one CSI simultaneously.

phyCAM-S+ (LVDS) Camera Interfaces (X1, X2)

phyCAM-S+ (LVDS) Camera Interfaces (X1, X2)

The table below shows the pinout of connector X1 and X2:

Pin # | Signal Name | Signal Type | Signal Level | Description |

1 | CAMx_DATA_IN+ | LVDS_I | - | LVDS Data+ |

2 | CAMx_DATA_IN- | LVDS_I | - | LVDS Data- |

3 | CAMx_CLOCK_OUT- | LVDS_O | - | LVDS Clock- |

4 | CAM_S_I2C_SDA | OD-BI | 3.3 V | I2C Data Signal |

5 | CAM_S_I2C_SCL | OD-BI | 3.3 V | I2C Clock Signal |

6 | CAMx_CLOCK_OUT+ | LVDS_0 | - | LVDS Clock+ |

7 | VCC_CAMx_S | PWR_O | 3.3 V | Power supply |

8 | GND | - | 0 V | Ground |

Pads | GND | - | 0 V | Ground |

PHYTEC phyCAM‑S+ Camera Connector (X1, X2)

Available phyCAM‑S+ cables:

PHYTEC Item no. | Length | Cable type |

WK262-0.2 | 20 cm | wires |

WK353-0.2 | 20 cm | CAT5 |

WK353-0.5 | 50 cm | CAT5 |

WK431-0.5 | 50 cm | USB3.0 |

The phyCAM‑S+ is particularly suitable for external camera installation. Usually, the recommended cable length is 5 m. The maximum achievable cable length, however, greatly depends on the operating parameters (e.g. power consumption, clock frequency, read-out mode) of the camera module and the overall device configuration. Under certain circumstances, longer cable lengths may be possible or shorter cable lengths may be required. Please consult with PHYTEC project engineers to determine the best configuration.

phyCAM-S+ Equalizer Configuration

Both phyCAM‑S+ interfaces have an equalizer to compensate for cable-dependent losses.

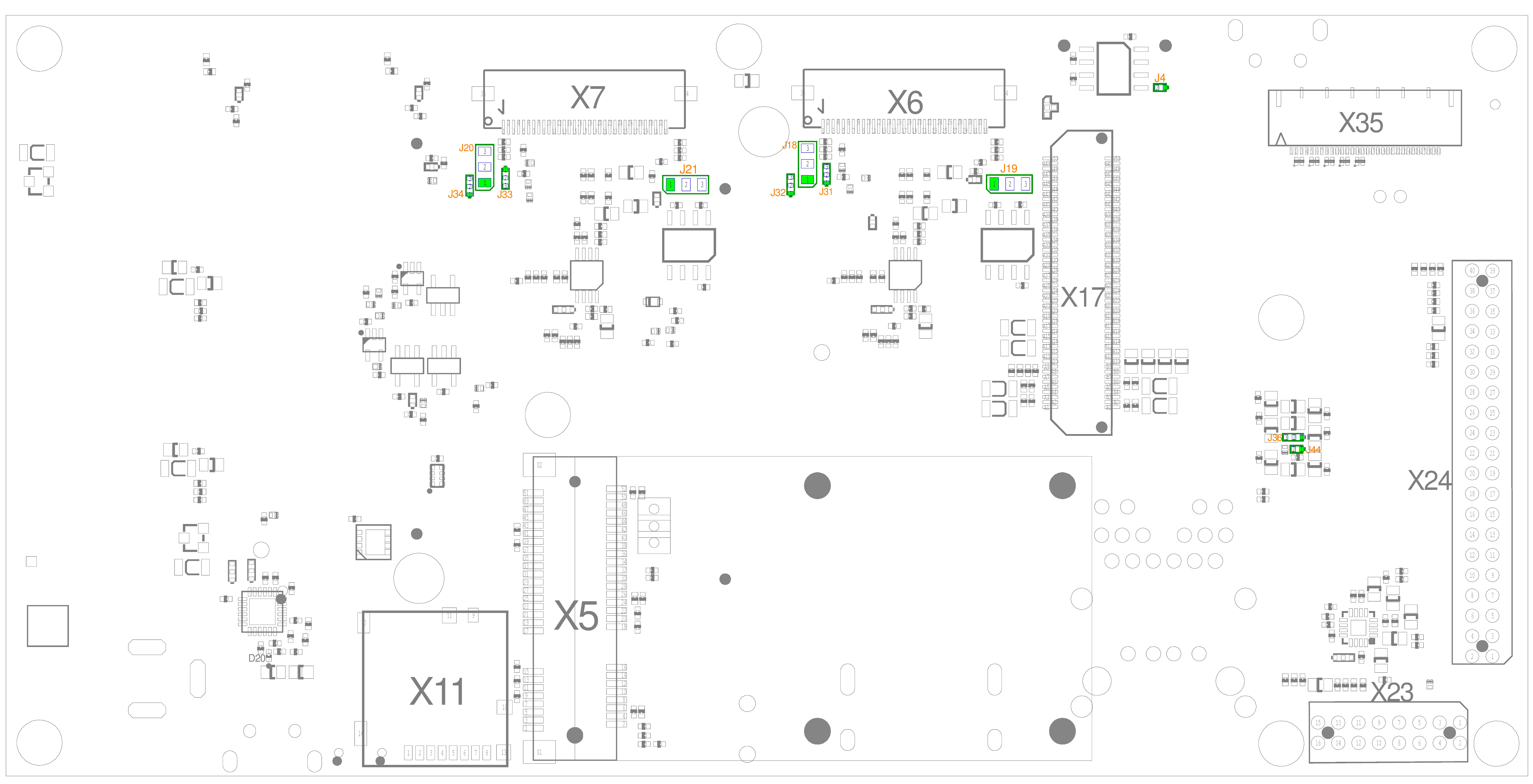

EQ1 (J32 / J34) | EQ0 (J31 / J33) | Equalization Level |

2+3 | 2+3 | Off |

2+3 | 1+2 | Low |

1+2 | 2+3 | Medium |

1+2 | 1+2 | High |

phyCAM-S+ Equalizer Configuration

Camera_0 (connected to IPU1_CSI0) as phyCAM‑S+ (X1)

The 1-channel 10-Bit LVDS random lock deserializer (U15) on the phyBOARD‑Nunki i.MX 6 is connected to the i.MX 6's camera sensor interface CSI0[1]of IPU#1. The LVDS deserializer converts the LVDS signals received at the header X1 on the carrier board to a 10-bit wide parallel data signal and separate clock. The camera interface is compatible with the PHYTEC phyCAM‑S+ camera interface standard.

Camera_1 (connected to IPU2_CSI1) as phyCAM-S(+) (X2)

The 1-channel 10-Bit LVDS random lock deserializer (U16) on the phyBOARD‑Nunki i.MX 6 is connected to the i.MX 6's camera sensor interface CSI1 of IPU#2. The LVDS deserializer converts the LVDS signals received at the header X2 on the carrier board to a 10-bit wide parallel data signal and separate clock. The camera interface is compatible with the PHYTEC phyCAM‑S+ camera interface standard.

| 1. | Only i.MX 6 with Dual-, or Quad core. i.MX 6 with Solo-, or DualLite core provide only one parallel camera interface and one IPU. |

phyCAM-P (Parallel) Camera Interfaces (X6, X7)

phyCAM-P (Parallel) Camera Interfaces (X6, X7)

The table below shows the pinout of connector X6 and X7:

Pin # | Signal Name | Signal Type | Signal Level | Description |

1 | VCC_CAMx_P | PWR_O | NS | Power Supply |

2 | CAMx_OE | 0 | VCC_CAMx_P | Output Enable |

3 | CAMx_VSET | Analog | - | Power Supply Voltage Set |

4 | CAMx_CTRL2 | I/O | VCC_CAMx_P | Control Signal 2 |

5 | CAMx_MCLK | O | VCC_CAMx_P | Camera Master Clock |

6 | GND | - | 0 V | Ground |

7 | CAMx_PCLK | I | VCC_CAMx_P | Camera Pixel Clock |

8 | GND | - | 0 V | Ground |

9 | CAMx_DD0 | I | VCC_CAMx_P | Camera Data 0 |

10 | CAMx_DD1 | I | VCC_CAMx_P | Camera Data 1 |

11 | GND | - | 0 V | Ground |

12 | CAMx_DD2 | I | VCC_CAMx_P | Camera Data 2 |

13 | CAMx_DD3 | I | VCC_CAMx_P | Camera Data 3 |

14 | GND | - | 0 V | Ground |

15 | CAMx_DD4 | I | VCC_CAMx_P | Camera Data 4 |

16 | CAMx_DD5 | I | VCC_CAMx_P | Camera Data 5 |

17 | GND | - | 0 V | Ground |

18 | CAMx_DD6 | I | VCC_CAMx_P | Camera Data 6 |

19 | CAMx_DD7 | I | VCC_CAMx_P | Camera Data 7 |

20 | GND | - | 0 V | Ground |

21 | CAMx_DD8 | I | VCC_CAMx_P | Camera Data 8 |

22 | CAMx_DD9 | I | VCC_CAMx_P | Camera Data 9 |

23 | GND | - | 0 V | Ground |

24 | CAMx_LV | I | VCC_CAMx_P | Camera HSYNC Signal |

25 | CAMx_FV | I | VCC_CAMx_P | Camera VSYNC Signal |

26 | GND | - | 0 V | Ground |

27 | CAMx_CTRL1 | I/O | VCC_CAMx_P | Control Signal 1 |

28 | CAMx_I2C_SCL | OD-BI | VCC_CAMx_P | I2C Clock Signal |

29 | CAMx_I2C_SDA | OD-BI | VCC_CAMx_P | I2C Data Signal |

30 | GND | - | 0 V | Ground |

31 | nCAM_RST | O | VCC_CAMx_P | Reset |

32 | VCC_CAMx_P | PWR_O | NS | Power Supply |

33 | VCC_CAMx_P | PWR_O | NS | Power Supply |

Pads | GND | - | 0 V | Ground |

PHYTEC phyCAM-P Connector (X6, X7)

Available phyCAM‑P cables:

PHYTEC Item no. | Length | Cable type |

WF062 | 12 cm | FFC |

WF043 | 20 cm | FFC |

WF046 | 30 cm | FFC |

The phyCAM‑P is particularly suitable for the internal camera installation. Usually, the recommended cable length is 30 cm. The maximum achievable cable length, however, greatly depends on the operating parameters (e.g. power consumption, clock frequency, read-out mode) of the camera module and the overall device configuration. Under certain circumstances, longer cable lengths may be possible or shorter cable lengths may be required. Please consult with PHYTEC project engineers to determine the best configuration.

The voltage suppy (VCC_CAM) and the signal voltages depend on the camera module in use. The phyCAM‑P Interface of the phyBOARD‑Nunki i.MX 6 is designed for the greatest possible compatibility with different phyCAM-P modules to easily use such devices without hardware customization. Further information on the control signals (for example CAM-CTRLx) can be found in the phyCAM manual (L-748e).

Camera_0 (connected to IPU1_CSI0) as phyCAM-P (X6)

The Parallel 0 camera interface of the i.MX 6 connects to CSI0 of IPU#1. It is brought out as a parallel interface on the phyCORE connector X6. The phyBOARD allows either camera module to connect with phyCAM‑P interface at connector X6 (33-pin FPC-connector, 0.5 mm pitch).

Camera_1 (connected to IPU2_CSI1) as phyCAM-P (X7)

The Parallel 1 camera interface of the i.MX 6 connects to CSI1[2]of IPU#2 It is brought out as a parallel interface on the phyCORE connector X7. The phyBOARD allows either camera module to connect with phyCAM‑P interface at connector X7 (33-pin FPC-connector, 0.5 mm pitch).

Warning

It is not possible to simultaneously connect a phyCAM-P and a phyCAM-S+ camera to one of the interfaces (Camera_0 or Camera_1). Selection of either phyCAM-P or phyCAM-S+ as interface type can be done at run time.

Tip

For more information on the PHYTEC camera interfaces phyCAM-P and phyCAM-S+, refer to the documentation delivered with the camera module (phyCAM manual L-748e).

| 2. | Only i.MX 6 with Dual-, or Quad core. i.MX 6 with Solo-, or DualLite core provide only one parallel camera interface and one IPU. |

phyCAM-M (MIPI CSI‑2) Camera Interface (X35)

phyCAM-M Interface (X35)

The table below shows the pinout of connector X35:

Pin # | Signal Name | Signal Type | Signal Level | Description |

1 | GND | - | 0 V | Ground |

2 | CSI-2 D0+ | LVDS_I | - | MIPI CSI-2 Data Lane |

3 | CSI-2 D0- | LVDS_I | - | MIPI CSI-2 Data Lane |

4 | GND | - | 0 V | Ground |

5 | CSI-2 D1+ | LVDS_I | - | MIPI CSI-2 Data Lane |

6 | CSI-2 D1- | LVDS_I | - | MIPI CSI-2 Data Lane |

7 | GND | - | 0 V | Ground |

8 | CSI-2 CLK+ | LVDS_I | - | MIPI CSI-2 Data Lane |

9 | CSI-2 CLK- | LVDS_I | - | MIPI CSI-2 Data Lane |

10 | GND | - | 0 V | Ground |

11 | CSI-2 D2+ | LVDS_I | - | MIPI CSI-2 Data Lane |

12 | CSI-2 D2- | LVDS_I | - | MIPI CSI-2 Data Lane |

13 | GND | - | 0 V | Ground |

14 | CSI-2 D3+ | LVDS_I | - | MIPI CSI-2 Data Lane |

15 | CSI-2 D3- | LVDS_I | - | MIPI CSI-2 Data Lane |

16 | GND | - | 0 V | Ground |

17 | GPIO1_00 | OD-BI | 3.3 V | CAM Ctrl 4 |

18 | GPIO5_25 | OD-BI | 3.3 V | CAM Ctrl 3 |

19 | GPIO5_24 | OD-BI | 3.3 V | CAM Ctrl 2 |

20 | GPIO5_23 | OD-BI | 3.3 V | CAM Ctrl 1 |

21 | GND | - | 0 V | Ground |

22 | CAM_I2C_SCL | OD-BI | 3.3 V | I²C Clock Signal |

23 | CAM_I2C_SDA | OD-BI | 3.3 V | I²C Data Signal |

24 | CAM_I2C_ADDR | O | 3.3 V | I²C Address Select |

25 | nCAM_RESET | O | 3.3 V | Reset |

26 | CAM_VCC_SELECT | OD-I | 3.3 V | VCC_CAM Select (open = 3.3 V, GND = 5 V) |

27 | GND | - | 0 V | Ground |

28 | VCC_CAM | PWR_O | 3.3 V / 5 V | Camera Power Supply |

29 | VCC_CAM | PWR_O | 3.3 V / 5 V | Camera Power Supply |

30 | VCC_CAM | PWR_O | 3.3 V / 5 V | Camera Power Supply |

phyCAM-M (MIPI CSI-2) Camera Connector (X35)

Available phyCAM‑M cable:

PHYTEC Item no. | Length | Cable type |

WF271 | 15 cm | Shielded FFC |

The phyCAM-M interface is based on the CSI-2 MIPI standard and also defines a connector for professional applications. phyCAM-M offers high compatibility for different camera modules to allow easy interchangeability in all phases of a project. The internal cable routing can be up to 15 cm and can be flexibly planned.

In addition to the data and clock line pairs provided in the CSI-2 standard (with up to 4 data lanes and one clock), an I²C bus is available as a configuration interface. In addition, the phyCAM-M camera modules have up to four control lines (3.3 V I/O) so that the special functions of the various camera sensors can be used.

The voltage supply (VCC_CAM) and the signal voltages depend on the camera module in use. The phyCAM‑P interface of the phyBOARD‑Nunki i.MX 6 is designed for the greatest possible compatibility with different phyCAM-P modules to easily use such devices without hardware customization. Further information on the control signals (for example CAM-CTRLx) can be found in the phyCAM manual (L-748e).

Camera_2 (connected to IPU1_CSI0) as phyCAM-M (X35)

The MIPI CSI-2 camera interface of the i.MX 6 connects to CSI0 of IPU#1. It is brought out on the phyCORE connector X3. The phyBOARD allows either camera module to connect with phyCAM‑M interface at connector X35 (30-pin FPC-connector, 0.5 mm pitch).

Tip

Depending on the configuration of the CSI2 IPU Bridge/Gasket and the internal multiplexer(s), Camera_0 and/or Camera_1 are not available if one or more MIPI compliant sensors are connected to the Camera_2 connector of the mapper.

Trigger/Strobe Connector (X8, X9)

Trigger/Strobe Connector (X8 and X9)

Many phyCAM modules are equipped with an additional header for controlling the image capturing. This allows for various configurations. For instance, a timed image capture can be started or two camera sensors can be synchronized with each other. The specific mode of operation depends on the sensor. Please refer to the phyCAM manual (L-748e)for further information. The table below shows the pinout of the connector X8 and X9:

Pin # | Signal Name | Signal Type | Signal Level | Description |

1 | CAMx_TRIGGER | O | VCC_CAMx_P/S | Trigger Output |

2 | GND | - | 0 V | Ground |

3 | CAMx_STROBE | I | VCC_CAMx_P/S | Strobe Input |

PHYTEC Trigger/Strobe Connector (X8, X9)

Available trigger/strobe cables:

PHYTEC Item no. | Length |

WK295 | 25 cm |

WK295-0.03 | 3 cm |

USB Connectivity

The phyBOARD-Nunki i.MX 6 provides one USB host and one USB OTG interface.

USB Host (X33)

USB Host (X33)

USB1 is accessible at connector X33 (USB Standard-A) located on the top of the phyBOARD and is configured as USB host. This interface is compliant with USB revision 2.0.

USB OTG (X14)

USB OTG (X14) with LED (D19)

The USB OTG interface is routed to X14. USB OTG devices are capable of initiating a session, controlling the connection, and exchanging host and peripheral roles between each other. This interface is compliant with USB revision 2.0.

LED D19 displays the status of USB_OTG_VBUS. If D19 is turned off, the USB OTG interface is configured as USB Device (e.g. as a serial console). In this case, the phyBOARD does not have to be powered by a host PC as the phyBOARD provides the needed voltage itself. If D19 is turned on, the USB OTG interface is configured as a USB Host like X33. That means the phyBOARD powers the connected USB Device.

Warning

If the USD OTG interface is configured as a host, do not short USB_OTG_VBUS to an external power supply. Doing so may cause damaging cross current!

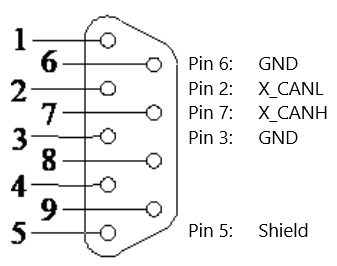

CAN Connectivity (X12, JP1)

CAN Interface (X12, JP1)

The Controller Area Network (CAN) bus offers a low-bandwidth, prioritized message fieldbus for serial communication between microcontrollers. It efficiently supports distributed real time control with a high level of security. The Flexible Controller Area Network (FLEXCAN1) module of the iMX 6 is a full implementation of the CAN protocol specification version 2.0B. It supports standard and extended message frames and supports bitrates of up to 1 Mbit/s.

The first interface (FLEXCAN1) of the Flexible Controller Area Network is accessible at connector X12 (2×5 pin header, 2.54 mm pitch).

Jumper JP1 can be mounted to add a 120 Ohm termination resistor across the CAN data lines if needed.

Suitable connection cables:

PHYTEC Item no. | Length | Remarks |

WF228 | 12 cm | 10-pole RM2.54 pin connector to 9-pole SUB-D male |

The table below shows the signal mapping of the CAN1 signals at connector X12.

Pin | Signal | Pin | Signal |

1 | NC | 2 | GND |

3 | X_CANL | 4 | X_CANH |

5 | GND | 6 | NC |

7 | NC | 8 | NC |

9 | Shield | 10 | NC |

Pin Assignment of CAN Connector X12

An adapter cable is included in the phyBOARD‑Nunki i.MX 6 Kit to facilitate the use of the CAN interface. The following figure shows the signal mapping of the adapter.

WF228 CAN Connector Signal Mapping

Secure Digital / MultiMedia Card (X11)

SD / MMC Connector (X11)

The phyBOARD-Nunki i.MX 6 provides a standard microSDHC card slot at X11 for connection to SD/MMC interface cards. It allows for an easy and convenient connection to peripheral devices such as SD and MMC cards. Power to the SD interface is supplied by inserting the appropriate card into the SD/MMC connector which features card detection, a lock mechanism, and a smooth extraction function by Push-in/Push-out of card.

An inserted SD card can be used as a boot source via S2. See Boot Mode for a description of the boot configuration.

The SD/MMC connector complies with High Speed Bus IF and can support up to Class 10 speed rating.

Suitable micro SD memory cards:

PHYTEC Item no. | Memory | Class | Temp. range |

MC057 | 1 GB | Class 4 | -25 / +85°C |

MC023 | 2 GB | Class 4 | -40 / +85°C |

MC042 | 4 GB | Class 4 | -25 / +85°C |

MC047 | 4 GB | Class 10 | -25 / +85°C |

MC051 | 32 GB | Class 10 | -25 / +85°C |

SATA (X18)

SATA Connector (X18)

The SATA II interface of the phyBOARD-Nunki i.MX 6 is a high-speed serialized ATA data link interface compliant with SATA Revision 3.0 (physical layer complies with SATA Revision 2.5). The interface includes an internal DMA engine, command layer, transport layer, link layer, and the physical layer. The interface is brought out at a standard SATA connector (X18) on the phyBOARD.

HDMI Connectivity (X10)

HDMI Connector (X10)

The phyBOARD-Nunki i.MX 6 provides a High-Definition Multimedia Interface (HDMI) which is compliant to HDMI 1.4a, DVI 1.0, HDCP 1.4. It supports a maximum pixel clock of up to 340 MHz for up to 720p at 100 Hz and 720i at 200 Hz, or 1080p at 60 Hz and 1080i/720i at 120 Hz HDTV display resolutions, and a graphic display resolution of up to 2048x1536 (QXGA). Audio streams reach a sampling rate of up to 192 kHz. Please refer to the i.MX 6 Applications Processor Reference Manual for more information.

The HDMI interface is brought out at a standard HDMI type A connector (X10) on the phyBOARD-Nunki i.MX 6 and is comprised of the following signal groups: three pairs of data signals, one pair of clock signals, an I²C bus which is exclusively for the HDMI interface, the Consumer Electronics Control (CEC) signal, and the hot plug detect (HPD) signal. All signals are routed from the phyCORE‑Connector to the HDMI receptacle through an HDMI Transmitter Port Protection and Interface Device. This device provides ESD protection and includes level shifting to shift the I²C interface signals and the hot plug detect signal from IO voltage (VCC3V3) to 5 V. The hot plug detect signal is pulled down to ground at the output of the protection device.

Warning

Ensure that all module connections do not exceed their expressed maximum voltage or current. Maximum signal input values are indicated in the corresponding controller User's Manual/Data Sheets. As damage from improper connections varies according to use and application, it is the user‘s responsibility to take appropriate safety measures to ensure that the module connections are protected from overloading through connected peripherals.

Universal Display Interface

LVDS Display Connector (X31)

LVDS Display Connector (X31)

At present, there are a few LVDS displays on the market with some kind of standardized interface. The LVDS display connector X31 is intended to connect these displays with screen diagonals ranging from 7” to 12.1” with different resolutions. The display connector X31 is a 30-pole receptacle with 1 mm pitch. The table below show the pinout of connector X31.

Pin # | Signal Name | Signal Type | Signal Level | Description |

1 | 3V3_UDI1 | PWR_O | 3.3 V | Display Power Supply |

2 | 3V3_UDI1 | PWR_O | 3.3 V | Display Power Supply |

3 | GND | - | 0 V | Ground |

4 | GND | - | 0 V | Ground |

5 | LVDS0_TX0- | LVDS_O | LVDS Data0- | |

6 | LVDS0_TX0+ | LVDS_O | LVDS Data0+ | |

7 | GND | - | 0 V | Ground |

8 | LVDS0_TX1- | LVDS_O | LVDS Data1- | |

9 | LVDS0_TX1+ | LVDS_O | LVDS Data1+ | |

10 | GND | - | 0 V | Ground |

11 | LVDS0_TX2- | LVDS_O | LVDS Data2- | |

12 | LVDS0_TX2+ | LVDS_O | LVDS Data2+ | |

13 | GND | - | 0 V | Ground |

14 | LVDS0_TX3- | LVDS_O | LVDS Data3- | |

15 | LVDS0_TX3+ | LVDS_O | LVDS Data3+ | |

16 | GND | - | 0 V | Ground |

17 | LVDS0_CLK- | LVDS_O | LVDS Clock- | |

18 | LVDS0_CLK+ | LVDS_O | LVDS Clock- | |

19 | GND | - | 0 V | Ground |

20 | USB_HUB_DM4 | USB_I/O | USB HUB Port 4 D- | |

21 | USB_HUB_DP4 | USB_I/O | USB HUB Port 4 D+ | |

22 | GND | - | 0 V | Ground |

23 | 5V_UDI1 | PWR_O | 5 V | Display Power Supply |

24 | 5V_UDI1 | PWR_O | 5 V | Display Power Supply |

25 | GND | - | 0 V | Ground |

26 | I2C1_SDA | OD-BI | 3.3 V | I²C1 Data |

27 | I2C1_CLK | OB-BI | 3.3 V | I²C1 Clock |

28 | GND | - | 0 V | Ground |

29 | UART3_RX_DATA | I | 3.3 V | UART3 In |

O | 3.3 V | CTRL0 (10k PU) | J50 (1+2) | |

30 | UART3_TX_DATA | O | 3.3 V | UART3 Out |

O | 3.3 V | CTRL1 (10k PU) | J51 (1+2) | |

Pads | GND | - | 0 V | Ground |

Universal Display Connector (X31)

Compatible connector housings:

Hirose DF19-30S-1C

Display Power Connector (X4)

Backlight and Display Control Connector (X4)

In order to support a backlight for the LVDS display, X4 provides the supply voltages and control signals necessary. The table below shows the pinout of X4:

Pin # | Signal Name | Signal Type | Signal Level | Description | |

1 | +24V_IN_FILTER | PWR_O | NS[3] | Backlight Power Supply | |

2 | GND | - | 0 V | Ground | |

3 | PWM1 | O | 3.3 V | Pulse width modulation | |

4 | nLVDS_DISP_EN | O | 3.3 V | Display Enable (10k PU) | J36 (2+3) |

5 V | Display Enable (10k PU) | J36 (1+2) | |||

5 | 5V_UDI2 | PWR_O | 5 V | Display Power Supply | |

6 | 3V3_UDI2 | PWR_O | 3.3 V | Display Power Supply | |

7 | GND | - | 0 V | Ground | |

Pads | GND | - | 0 V | Ground | |

Universal Display Connector (X4)

Compatible connector housings:

Molex 51021-0700

| 3. | +24V_FILTER is the external supply voltage from X19 or X20 secured against transients (26.4 V). Because of this, the voltage level depends on the connected power supply and is not specified here. |

Audio / Video Connectors (X23, X24)

Audio / Visual Connectors (X23, X24)

The Audio/Video (A/V) connectors X23 and X24 provide an easy way to add typical A/V functions and features to the phyBOARD-Nunki i.MX 6. Standard interfaces such as parallel display, I2S, and I2C as well as different supply voltages are available at the two A/V female dual entry connectors. One special feature of these connectors are their connectivity from the bottom or the top of the PCB. The pinout of the A/V connectors are shown below.

The A/V connector is intended for use with phyBOARD Expansion Boards[4]and to add specific audio/video connectivity with custom expansion boards.

A/V connector X24 makes all signals for display connectivity available, while X23 provides signals for audio and touch screen connectivity, as well as an I2C bus and additional control signals.

Warning

To avoid accidentally changing the boot configuration, please consider that the LCD data signals shown in the pinout tableare boot configuration pins which must not be driven by any device on the baseboard during reset. Please refer to 6.2 “Boot Drive Selection and Configuration” in the phyCORE-i.MX 6 hardware manual or to the i.MX 6 Reference Manual for more information about the boot configuration.

Pin # | Signal Name | Signal Type | Signal Level | Description |

1 | X_AUD5_TXFS | O | 3.3 V | AUD5 transmit frame sync |

2 | X_AUD5_TXC | O | 3.3 V | AUD5 transmit bit clock |

3 | X_AUD5_TXD | O | 3.3 V | AUD5 transmit data |

4 | X_AUD5_RXD | I | 3.3 V | AUD5 receive data |

5 | LCD_PWCTRL | O | 3.3 V | LCD power control |

6 | AV_INT | I/O | 3.3 V | A/V interrupt |

| X_nRESET | I/O | 3.3 V | Global Reset (J15 1+2) |

X_LCD_RESET | O | 3.3 V | Reset LCD (J15 2+3) | |

8 | GND | - | 0 V | Ground |

9 | TS_X- | Analog | 1.8 V | Touch X- |

10 | TS_X+ | Analog | 1.8 V | Touch X+ |

11 | TS_Y- | Analog | 1.8 V | Touch Y- |

12 | TS_Y+ | Analog | 1.8 V | Touch Y+ |

13 | GND | - | 0 V | Ground |

14 | +3V3 | PWR_O | 3.3 V | Display Power Supply |

15 | I2C1_SDA | OD-BI | 3.3 V | I2C1 data |

16 | I2C1_SCL | OD-Bi | 3.3 V | I2C1 clock |

PHYTEC A/V Connector (X23)

Pin # | Signal Name | Signal Type | Signal Level | Description |

1 | LCD_DATA16 | O | 3.3 V | LCD Data16 |

2 | GND | - | 0 V | Ground |

3 | LCD_DATA18 | O | 3.3 V | LCD Data16 |

4 | LCD_DATA17 | O | 3.3 V | LCD Data17 |

5 | GND | - | 0 V | Ground |

6 | LCD_DATA19 | O | 3.3 V | LCD Data19 |

7 | LCD_DATA21 | O | 3.3 V | LCD Data21 |

8 | LCD_DATA20 | O | 3.3 V | LCD Data20 |

9 | LCD_DATA23 | O | 3.3 V | LCD Data23 |

10 | LCD_DATA22 | O | 3.3 V | LCD Data22 |

11 | LCD_DATA08 | O | 3.3 V | LCD Data22 |

12 | GND | - | 0 V | Ground |

13 | LCD_DATA10 | O | 3.3 V | LCD Data10 |

14 | LCD_DATA09 | O | 3.3 V | LCD Data09 |

15 | GND | - | 0 V | Ground |

16 | LCD_DATA11 | O | 3.3 V | LCD Data11 |

17 | LCD_DATA13 | O | 3.3 V | LCD Data13 |

18 | LCD_DATA12 | O | 3.3 V | LCD Data12 |

19 | LCD_DATA15 | O | 3.3 V | LCD Data15 |

20 | LCD_DATA14 | O | 3.3 V | LCD Data14 |

21 | LCD_DATA00 | O | 3.3 V | LCD Data09 |

22 | GND | - | 0 V | Ground |

23 | LCD_DATA02 | O | 3.3 V | LCD Data09 |

24 | LCD_DATA01 | O | 3.3 V | LCD Data09 |

25 | GND | - | 0 V | Ground |

26 | LCD_DATA03 | O | 3.3 V | LCD Data09 |

27 | LCD_DATA05 | O | 3.3 V | LCD Data09 |

28 | LCD_DATA04 | O | 3.3 V | LCD Data09 |

29 | LCD_DATA07 | O | 3.3 V | LCD Data09 |

30 | LCD_DATA06 | O | 3.3 V | LCD Data09 |

31 | LCD_CLK | O | 3.3 V | LCD Clock |

32 | GND | - | 0 V | Ground |

33 | LCD_HSYNC | O | 3.3 V | LCD Horizontal Sync |

34 | LCD_ENABLE | O | 3.3 V | LCD Output Enable |

35 | GND | - | 0 V | Ground |

36 | LCD_VSYNC | O | 3.3 V | LCD Vertical Sync |

37 | PWM1 | O | 3.3 V | Pulse width modulation |

38 | GND | - | 0 V | Ground |

39 | +5V | PWR_O | 5 V | Display Power Supply |

40 | +24V_FILTER | PWR_O | NS[5] | Backlight power supply |

PHYTEC A/V Connector (X24)

Jumper J15 connects either signal X_LCD_RESET or signal X_nRESET_OUT to pin 7 of X15.

J15 | Description |

1+2 | X_nRESET |

2+3 | X_LCD_RESET |

A/V Jumper Configuration (J15)

| 4. | Please find additional information on phyBOARD Expansion Boards in phyBOARD Expansion Boards Application Guide L-793. |

| 5. | +24V_FILTER is the external supply voltage from X19 or X20 secured against transients (26.4 V). Because of this, the voltage level depends on the connected power supply and is not specified here. |

Mini PCIe (X5)

Mini PCIe Connector (X5)

The 1-lane PCI express interface of the phyBOARD-Nunki i.MX 6 provides PCIe Gen. 2.0 functionality which supports 5 Gbit/s operations. Furthermore, the interface is fully backwards compatible with the 2.5 Gbit/s Gen. 1.1 specification. Various control signals are implemented with GPIOs. The PCIe interface is brought out at the Mini PCIe connector X5. The SIM/UIM card signals of a connected PCIe module can be made available at the Expansion Connector.

The table below shows a complete overview of the Mini PCI Express connector pin assignment.

Pin # | Signal name | Signal Type | Signal Level | Description |

1 | X_ECSPI2_MOSI/PCIe_nWAKE | I | 3.3 V | PCIe nWAKE |

2 | +3V3 | PWR_O | 3.3 V | 3.3 V power supply |

3 | X_ECSPI2_SS0/PCIe_COEX1 | I/O | 3.3 V | Coexistence pins for wireless solutions |

4 | GND | - | 0 V | Ground |

5 | X_CSI1_DATA06/PCIe_COEX2 | I/O | 3.3 V | Coexistence pins for wireless solutions |

6 | +1V5 | PWR_O | 1.5 V | 1.5 V power supply[6] |

7 | X_ECSPI2_SCLK/PCIe_nCLKREQ | I | 3.3 V | Clock request support |

8 | X_SIM_VCC | PWR_I | - | UIM_PWR[7] |

9 | GND | - | 0 V | Ground |

10 | X_SIM_IO | I/O | - | UIM_DATA[7] |

11 | X_PCIe0_CLK- | LVDS_O | - | PCIe0 reference clock - |

12 | X_SIM_CLK | O | - | UIM_CLK[7] |

13 | X_PCIe0_CLK+ | LVDS_O | - | PCIe0 reference clock + |

14 | X_SIM_RST | O | - | UIM_RESET[7] |

15 | GND | - | 0 V | Ground |

16 | X_SIM_VPP | PWR_I | - | UIM_VPP[7] |

17 | RSVD3 | - | - | Not connected |

18 | GND | - | 0 V | Ground |

19 | RSVD4 | - | - | Not connected |

20 | X_EIM_DA14/PCIe_nW_DISABLE | O | 3.3 V | nWireless disable signal |

21 | GND | - | - | Ground |

22 | X_ECSPI2_MISO/PCIe_nPERST | O | 3.3 V | Functional card reset by GPIO or X_nRESET |

23 | X_PCIe_RXN | LVDS_I | - | PCIe receive - |

24 | +3V3 | PWR_O | 3.3 V | 3.3 V power supply |

25 | X_PCIe_RXP | LVDS_I | - | PCIe receive + |

26 | GND | - | 0 V | Ground |

31 | X_PCIe_TXN | LVDS_O | - | PCIe transmit - |

32 | X_I2C1_SDA | OD-BI | 3.3 V | I2C1 data |

33 | X_PCIe_TXP | LVDS_O | - | PCIe transmit + |

34 | GND | - | 0 V | Ground |

35 | GND | - | 0 V | Ground |

36 | USB_HUB_DM3 | USB_I/O | - | USB host data -[8] |

37 | GND | - | 0 V | Ground |

38 | USB_HUB_DP3 | USB_I/O | - | USB host data +[8] |

39 | +3V3 | PWR_O | 3.3 V | 3.3 V power supply |

40 | GND | - | 0 V | Ground |

41 | +3V3 | PWR_O | 3.3 V | 3.3 V power supply |

42 | TP2 | O | NS | Test point for nLED_WWAN |

43 | GND | - | 0 V | Ground |

44 | TP3 | O | NS | Test point for nLED_WLAN |

45 | RSVD9 | - | - | Not connected |

46 | TP4 | O | NS | Test point for nLED_WPAN |

47 | RSVD10 | - | - | Not connected |

48 | +1V5 | PWR_O | 1.5 V | 1.5 V power supply[6] |

49 | RSVD11 | - | - | Not connected |

50 | GND | - | 0 V | Ground |

51 | RSVD12 | - | - | Not connected |

52 | +3V3 | PWR_O | 3.3 V | 3.3 V power supply |

Pads | GND | - | 0 V | Ground |

Mini PCI Connector (X5)

| 6. | The 1.5 V voltage can be switched OFF with signal ENET_TX_EN. |

| 7. | User Identity Module (UIM) signals. |

| 8. | Caution! There is no protective circuit for the USB interfaces brought out at the Mini PCI Express controller (X5) |

Expansion Connector (X17)

Expansion Connector (X17)

Expansion connector X17 provides an easy way to add other functions and features to the phyBOARD‑Nunki. Standard interfaces such as JTAG, USB, UART, SDIO, SPI, and I2C as well as different supply voltages and some GPIOs are available at the expansion female connector.

This interface is compliant with JTAG specification IEEE 1149.1 or IEEE 1149.7. No jumper settings are necessary to use the JTAG port.

The expansion connector is intended to add specific functions with custom expansion boards. Some signals can be multiplexed to perform different functions. Refer to the phyCORE hardware manual and the chip vendor documentation (NXP iMX6) for multiplexing information.

The Expansion Connector X17 is compatible with Samtec BSH-050-01-L-D-A-TR (PHYTEC part number: VB222). The board spacing between PBA-C-11 and the expansion board is 5 mm. The highest component on PBA-C-11 (without Mini PCIE (X5) and display adapter (X23/24)) is 2.5 mm high. Below is a representation of the usable board area for an expansion board, the position of the connector, and the available mounting holes. The drawing is also available for download as a DXF file.

phyBOARD-Nunki i.MX 6 Expansion Port Space Limitations (Backside ofBoard)

The tables below show the pinout of the expansion connector.

Pin # | Signal Name | Signal Type | Signal Level | Description |

A1 | +3V3 | PWR_O | 3.3 V | Peripherals supply voltage |

A2 | +3V3 | PWR_O | 3.3 V | Peripherals supply voltage |

A3 | GND | - | 0 V | Ground |

A4 | GND | - | 0 V | Ground |

A5 | +3V3 | PWR_O | 3.3 V | Peripherals supply voltage |

A6 | +3V3 | PWR_O | 3.3 V | Peripherals supply voltage |

A7 | +3V3_CORE | PWR_O | 3.3 V | phyCORE supply voltage |

A8 | +3V3_CORE | PWR_O | 3.3 V | phyCORE supply voltage |

A9 | GND | - | 0 V | Ground |

A10 | GND | - | 0 V | Ground |

A11 | VCC_RESERVED | PWR_O | - | Reserved |

A12 | VCC_RESERVED | PWR_O | - | Reserved |

A13 | GND | - | 0 V | Ground |

A14 | GND | - | 0 V | Ground |

A15 | PWRGOOD_3V3 | O | 3.3 V | phyCORE power-good signal |

A16 | +3V3_LOGIC | REF_O | 3.3 V | phyCORE IO reference voltage |

A17 | X_nRESET | I/O | 3.3 V | Global reset signal |

A18 | GND | - | 0 V | Ground |

A19 | USB_HUB_PRTPW2 | I | 3.3 V | Control signal current limiting IO switch on |

A20 | USB_HUB_nOSC2 | O | 3.3 V | Control signal Overcurrentdetection |

A21 | GND | - | 0 V | Ground |

A22 | USB_HUB_DM2 | USB_I/O | - | USB HUB Port 2 D- |

A23 | USB_HUB_DP2 | USB_I/O | - | USB HUB Prot 2 D+ |

A24 | GND | - | 0 V | Ground |

A25 | X_SD3_CMD | I/O | 3.3 V | SDIO3 Command |

A26 | GND | - | 0 V | Ground |

A27 | X_SD3_CLK | I/O | 3.3 V | SDIO3 Clock |

A28 | GND | - | 0 V | Ground |

A29 | X_SD3_DATA0 | I/O | 3.3 V | SDIO3 Data0 |

A30 | X_SD3_DATA1 | I/O | 3.3 V | SDIO3 Data1 |

A31 | GND | - | 0 V | Ground |

A32 | X_SD3_DATA2 | I/O | 3.3 V | SDIO3 Data2 |

A33 | X_SD3_DATA3 | I/O | 3.3 V | SDIO3 Data3 |

A34 | GND | - | 0 V | Ground |

A35 | X_SD3_DATA4 | I/O | 3.3 V | SDIO3 Data4 |

A36 | X_SD3_DATA5 | I/O | 3.3 V | SDIO3 Data5 |

A37 | GND | - | 0 V | Ground |

A38 | X_SD3_DATA6 | I/O | 3.3 V | SDIO3 Data6 |

A39 | X_SD3_DATA7 | I/O | 3.3 V | SDIO3 Data7 |

A40 | GND | - | 0 V | Ground |

A41 | X_UART3_RTS_B | I/O | 3.3 V | UART3 Ready to Send |

A42 | X_UART3_CTS_B | I/O | 3.3 V | UART3 Clear to Send[9] |

A43 | GND | - | 0 V | Ground |

A44 | X_UART3_TX_DATA | O | 3.3 V | UART3 Tx Data |

A45 | GND | - | 0 V | Ground |

A46 | X_UART3_RX_DATA | I | 3.3 V | UART3 Rx Data |

A47 | GND | - | 0 V | Ground |

A48 | I2C1_SDA | OD-BI | 3.3 V | I²C1 SDA |

A49 | I2C1_SCL | OD-BI | 3.3 V | I²C1 SCL |

A50 | GND | - | 0 V | Ground |

PHYTEC Expansion Connector X17 Row A

Pin # | Signal Name | Signal Type | Signal Level | Description |

B1 | +5V | PWR_O | 5 V | Peripherals supply voltage |

B2 | +5V | PWR_O | 5 V | Peripherals supply voltage |

B3 | GND | - | 0 V | Ground |

B4 | GND | - | 0 V | Ground |

B5 | +5V | PWR_O | 5 V | Peripherals supply voltage |

B6 | +5V | PWR_O | 5 V | Peripherals supply voltage |

B7 | +24V_IN_FILTER | PWR_O | NS | External supply voltage |

B8 | +24V_IN_FILTER | PWR_O | NS | External supply voltage |

B9 | GND | - | 0 V | Ground |

B10 | GND | - | 0 V | Ground |

B11 | X_SIM_VCC | PWR_I | - | Mini PCIe SIM VCC (X5) |

B12 | X_SIM_VPP | PWR_I | - | Mini PCIe SIM VPP (X5) |

B13 | X_SIM_RST | I | - | Mini PCIe SIM RST (X5) |

B14 | X_SIM_IO | I/O | - | Mini PCIe SIM IO (X5) |

B15 | X_SIM_CLK | I | - | Mini PCIe SIM CLK (X5) |

B16 | GND | - | 0 V | Ground |

B17 | X_JTAG_TMS | I | 3.3 V | JTAG Interface |

B18 | X_JTAG_TCK | I | 3.3 V | JTAG Interface |

B19 | GND | - | 0 V | Ground |

B20 | X_JTAG_TDO | O | 3.3 V | JTAG Interface |

B21 | X_JTAG_TDI | I | 3.3 V | JTAG Interface |

B22 | GND | - | 0 V | Ground |

B23 | X_JTAG_TRSTB | I | 3.3 V | JTAG Interface |

B24 | X_PWM1_OUT | I/O | 3.3 V | PWM1 OUT |

B25 | GND | - | 0 V | Ground |

B26 | GPIO1_28 | I/O | 2.8 V | GPIO (R8 at PCM-058 needs to unmount) |

B27 | GPIO4_9 | I/O | 3.3 V | GPIO, shared with X23 |

B28 | GND | - | 0 V | Ground |

B29 | GPIO4_6 | I/O | 3.3 V | GPIO, shared with X23 |

B30 | GPIO4_7 | I/O | 3.3 V | GPIO, shared with X23 |

B31 | GND | - | 0 V | Ground |

B32 | GPIO4_8 | I/O | 3.3 V | GPIO, shared with X23 |

B33 | GPIO1_30/nLVDS_DISP_EN | I/O | 2.8 V | GPIO, shared with X4 |

B34 | GND | - | 0 V | Ground |

B35 | GPIO1_29/nLCD_PWCTRL | I/O | 2.8 V | GPIO, shared with X23 |

B36 | GPIO1_27/CAN_EN | I/O | 2.8 V | GPIO, shared with U25 |

B37 | GPIO1_26/nEN_VCC1V5 | I/O | 2.8 V | GPIO, shared with U25 |

B38 | GND | - | 0 V | Ground |

B39 | X_ECSPI1_SCLK | O | 3.3 V | SPI1 Clock |

B40 | X_ECSPI1_MOSI | O | 3.3 V | SPI1 MOSI |

B41 | X_ECSPI1_MISO | I | 3.3 V | SPI1 MISO |

B42 | GND | - | 0 V | Ground |

B43 | X_ECSPI1_SS0 | O | 3.3 V | SPI1 Chip Select09 |

B44 | X_ECSPI2_SS1 | O | 3.3 V | SPI2 Chip Select19 |

B45 | X_ECSPI2_SS0 | O | 3.3 V | SPI2 Chip Select0 |

B46 | GND | - | 0 V | Ground |

B47 | X_ECSPI2_SCLK | O | 3.3 V | SPI2 Clock |

B48 | X_ECSPI2_MOSI | O | 3.3 V | SPI2 MOSI |

B49 | X_ECSPI2_MISO | I | 3.3 V | SPI2 MISO |

B50 | GND | - | 0 V | Ground |

PHYTEC Expansion Connector X17 Row B

| 9. | i.MX 6 Boot configuration pin ensures a High-Z state before a reset state. |

Multicolor (RGB) LED (D1)

The phyBOARD-Nunki i.MX 6 provides one multicolor (RGB) LED (D1) (phyBOARD-Nunki i.MX 6 Component Placement (Top) for user applications. The colors can be controlled via the LED dimmer IC at U21. The LED dimmer can be accessed via I2C1 at address 0x62 and dynamically controls the LED with PWM signals.

Buttons and Switches

Boot Mode (S2) and System Reset Buttons (S1)

Boot Mode (S2)

The phyBOARD-Nunki i.MX 6 has two defined boot sequences which can be selected by configuring switch S2.

Boot Mode | Description |

Boot mode 0 (S2 = off) | Boot from NAND |

Boot mode 1 (S2 = on) | Boot from SD/MMC 1 |

Boot Mode Configuration (S2)

System Reset Button (S1)

The phyBOARD-Nunki i.MX 6 is equipped with a system reset button at S1. Pressing this button will hold the X_nRESET pin (X3‑D32) of the phyCORE SOM low, causing the module and all peripherals (power on reset) on the carrier board to be reset when the button is released.

RTC

The internal RTC can be used as an accurate time source (typically 20 ppm) for the applied application. As long as the phyBOARD is powered by an external power supply, the Gold-Cap capacitor will be charged. In the event of an external power failure, the Gold-Cap continues to supply the RTC with power. Gold-caps have an advantage over lithium cells in that they can be charged and discharged without additional circuitry. However, the self-discharge with the Gold-Cap capacitor (depending on the design) depends on the duration of the charging process. Typically, the Gold-Cap used on the phyBOARD can supply the RTC for > 15 days (@ 20 ° C) or > 8 days (@ 40 ° C) after a charge time of 100 hours.

System Level Customizing

Introduction

This section is for advanced developers who want to design custom expansion boards or display adapters. It includes detailed information on the different interfaces and features of the phyBOARD-Nunki at a system level.

System Level Hardware Information

Differences in SOM Pinout

To support all features of the phyBOARD‑Nunki i.MX 6, the BSP provides assigned functions different from what is described in the pinout table of the phyCORE‑i.MX 6 hardware manual to some pins of the phyCORE‑i.MX 6. The table belowlists all pins with functions different from what is described in the SOM's pinout table.

Tip

The information given in the “SIGNAL TYPE” column is from the SOM’s perspective.

Pin# | Signal | Signal Type | Signal Level | Description |

A25 | X_EIM_DA13 | I/O | 3.3 V | Muxed as GPIO3_13 für X17 GPIO function |

A42 | X_EIM_BCLK | I | 3.3 V | Muxed as nSD1_CD (µSD Card Detection) |

A43 | X_ECSPI2_MISO | O | 3.3 V | Muxed as PCIe_nPERST for X5 |

A45 | X_ECSPI2_SS0 | I/O | 3.3 V | Muxed as PCIe_COEX1 for X5 |

A67 | X_ENET_TXER | O | 3.3 V | Muxed as GPIO4_05 for X8 trigger signal |

A68 | X_ENET_RXD0 | O | 2.8 V | Muxed as GPIO1_27 for CAN enable |

A69 | X_ENET_RXD1 | O | 2.8 V | Muxed as GPIO1_26 for nEN_VCC1V5 (PCIe) |

B26 | X_EIM_DA14 | O | 3.3 V | Muxed as PCIe_nW_DISABLE for X5 |

B39 | X_XSI1_DAT07 | I/O | 3.3 V | Muxed AV_INT for X23 AV connector |

B40 | X_XSI1_DAT06 | I/O | 3.3 V | Muxed PCIe_COEX2 for X5 |

B41 | X_XSI1_DAT05 | O | 3.3 V | Muxed EN_SWITCH for U31 |

B45 | X_ECSPI2_SCLK | I | 3.3 V | Muxed PCIe_nCLKREQ |

B46 | X_ECSPI2_RDY | O | 3.3 V | Muxed as GPIO5_02 for X9 trigger signal |

B47 | X_ECSPI2_MOSI | I | 3.3 V | Muxed PCIe_nWAKE |

B67 | X_ENET_TXD0 | I/O | 2.8 V | Muxed as GPIO1_28 for X17 GPIO function |

B69 | X_ENET_TXD0 | O | 2.8 V | Muxed as nLVDS_DISP_EN for X4 |

| B70 | X_ENET_TXD1 | O | 2.8 V | Muxed as nLCD_PWCTRL for X23 |

C16 | X_SPDIF_OUT | I | 3.3 V | Muxed INT_RES_TOUCH |

C52 | X_CSI0_DAT6 | I/O | 3.3 V | Muxed as GPIO5_24 for X32 |

C53 | X_CSI0_DAT5 | I/O | 3.3 V | Muxed as GPIO5_23 for X32 |

C55 | X_CSI0_DAT4 | I | 3.3 V | Muxed as GPIO5_22 for X9 strobe signal |

D13 | X_KEY_COL2 | I | 3.3 V | Muxed as GPIO4_10 for X8 strobe signal |

D47 | X_CSI0_DAT7 | I/O | 3.3 V | Muxed as GPIO5_25 for X32 |

Specifically used Pins on the phyCORE-Connector

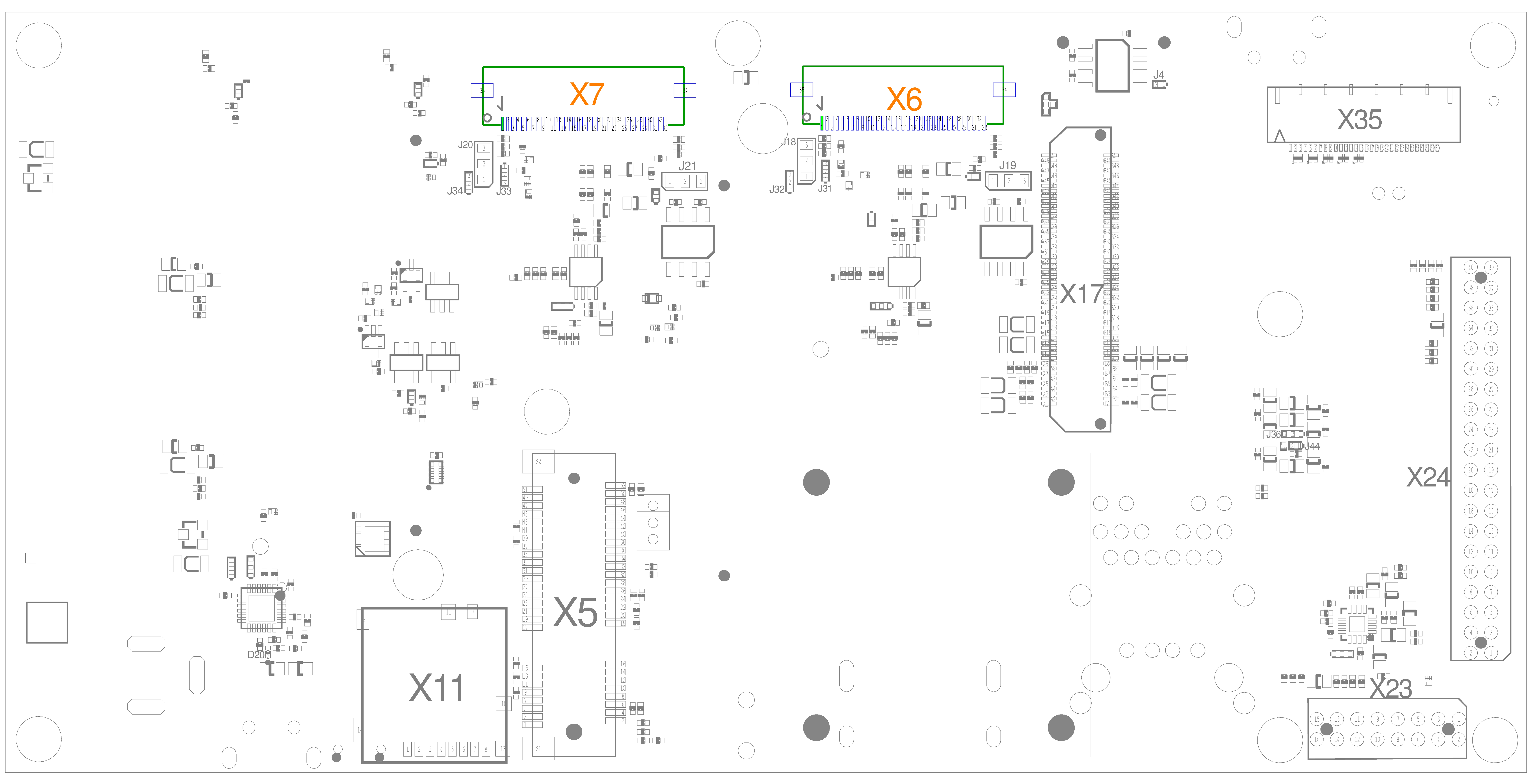

Soldering Jumpers

Numerous jumpers and resistors allow the user to configure the phyBOARD according to specific design needs.

Warning

Due to the small footprint of the jumpers PHYTEC does not recommend manual jumper modifications. This might also render the warranty invalid. Please contact the PHYTEC sales team if you need one of the configurations described below.

The following table lists all jumpers and resistors as well as describing their function.

Jumper / Resistor | Description | Section |

J18-J21 | Jumper for phyCAM‑P CTRL1 and CTRL2 | - |

J31-J34 | Jumper for phyCAM‑S+ equalizer configuration | phyCAM-S+ Equalizer Configuration |

J44 | Route nLVDS_DISP_EN to display power connector | Display Power Connector |

J36 | Voltage level for nLVDS_DISP_EN switching +3.3 V, +5 V | Display Power Connector |

J23 | Connects CAN_SHIELD with Ground | CAN Connectivity |

J4 | Connects USB OTG ID pin with Ground | Configuring the OTG Operating Mode |

Soldered Jumpers on the phyBOARD-Nunki

Jumper Positions (Top)

Jumper Positions (Bottom)

I2C Connectivity

The I2C1 interface of the i.MX 6 is available at different connectors on the phyBOARD‑Nunki. The following table provides a list of the connectors and pins with I2C connectivity.

Connector | Location |

Expansion connector X17 | pin A48 (I2C1_SDA) |

A/V connector X23 | pin 15 (I2C1_SDA) |

Universal Display Connector X31 | pin 26 (I2C1_SDA) |

Mini PCIe X5 | pin 32 (I2C1_SDA) |

I2C1 Connectivity

To avoid any conflicts when connecting external I2C devices to the phyBOARD‑Nunki, the addresses of the on-board I2C devices must be considered. The table below lists the addresses already in use. Note that the table only shows the default address.

Board | Prod. No. | Device | Address used |

I2C3 | |||

phyCORE-i.MX 6 | PCM-058 | EEPROM | 0x50 |

PMIC | 0xB0, 0xB1 | ||

I2C1 | |||

phyBOARD-Nunki | PBA-C-11 | Touch controller | 0x44 |

Multi color LED | 0x62 | ||

RTC | 0x68 | ||

phyCAM | 0x45, 0x48, 0x4A, 0x4C, 0x4E, 0x5A, 0x5C, 0x5D, 0x5E | ||

Screen AV adapter | PEB-AV-02 | GPIO Expander | 0x41 |

I2C Addresses in Use

USB OTG Connectivity

Configuring the OTG Operating Mode (J4)

Jumper J4 configures the OTG operating mode with the X_USB_OTG_ID signal. By default, this resistor is not mounted, which leaves the ID pin floating. This configures the OTG interface as device, or according to the configuration of the connected USB device. Mounting a 10 kΩ resistor connects the OTG1_ID pin to GND, forcing the OTG interface into host mode.

Revision History

Date | Version # | Changes in this manual |

09.05.2018 | L-852 e-1 | First edition. |

10.11.2019 | L-852e.A2 | Added Nunki Expansion Port Space Limitation Picutre |

| 24.04.2020 | L-852e.A3 | Updated to pyhBOARD-Nunki Carrier Board (1489.3) |