Hardware Manual - phyCORE-STM32MP15x/phyBOARD-Sargas (1534.1/1517.2) (L-875e.A2)

Table of Contents

Preface

As a member of PHYTEC's phyCORE® product family, the phyCORE‑STM32MP15x is one of a series of PHYTEC System on Modules (SOMs) that can be populated with different controllers and, therefore, offers various functions and configurations. PHYTEC supports a variety of 8/16/32/64 bit controllers in two ways:

(1) As the basis for Rapid Development Kits which serve as a reference and evaluation platform

(2) As insert-ready, fully functional phyCORE® OEM modules, which can be embedded directly into the user’s peripheral hardware design.

Implementation of an OEM-able SOM subassembly as the "core" of your embedded design allows for increased focus on hardware peripherals and firmware without expending resources to "re-invent" microcontroller circuitry. Furthermore, much of the value of the phyCORE® module lies in its layout and test.

Production-ready Board Support Packages (BSPs) and Design Services for our hardware will further reduce development time and risk and allows for increased focus on product expertise. Take advantage of PHYTEC products to shorten time-to-market, reduce development costs, and avoid substantial design issues and risks. With this new innovative full system solution, new ideas can be brought to market in the most timely and cost-efficient manner.

For more information go to:

http://www.phytec.de/de/leistungen/entwicklungsunterstuetzung.html

or

http://www.phytec.eu/europe/oem-integration/evaluation-start-up.html

Ordering Information

The part numbering of the phyCORE has the following structure:

Product Specific Information and Technical Support

In order to receive product-specific information on all future changes and updates, we recommend registering at:

http://www.phytec.de/de/support/registrierung.html or http://www.phytec.eu/europe/support/registration.html

For technical support and additional information concerning your product, please visit the support section of our website which provides product-specific information, such as errata sheets, application notes, FAQs, etc.

https://www.phytec.de/produkte/system-on-modules/phycore-stm32mp15x/

or

https://www.phytec.eu/en/produkte/system-on-modules/phycore-stm32mp15x

Declaration of Electro Magnetic Conformity of the PHYTEC phyCORE®‑STM32MP15x

PHYTEC System on Module (henceforth products) are designed for installation in electrical appliances or as dedicated Evaluation Boards (i.e.: for use as a test and prototype platform for hardware/software development) in laboratory environments.

Warning

PHYTEC products lacking protective enclosures are subject to damage by ESD and, therefore, must be unpacked, handled, or operated in environments in which sufficient precautionary measures have been taken with respect to ESD dangers. It is also necessary that only appropriately trained personnel (such as electricians, technicians, and engineers) handle and/or operate these products. Moreover, PHYTEC products should not be operated without protection circuitry if connections to the product's pin header rows are longer than 3 m.

PHYTEC products fulfill the norms of the European Union’s Directive for Electro Magnetic Conformity only in accordance with the descriptions and rules of usage indicated in this hardware manual (particularly with respect to the pin header row connectors, power connector, and serial interface to a host-PC).

Implementation of PHYTEC products into target devices, as well as user modifications and extensions of PHYTEC products, is subject to renewed establishment of conformity to, and certification of, Electro Magnetic Directives. Users should ensure conformance following any modifications to the products as well as the implementation of the products into target systems.

Product Change Management and Information Regarding Parts Populated on the SOM / Carrier Board

With the purchase of a PHYTEC SOM / Carrier Board, you will, in addition to our HW and SW offerings, receive free obsolescence maintenance service for the hardware we provide. Our PCM (Product Change Management) Team of developers, is continuously processing, all incoming PCNs (Product Change Notifications) from vendors and distributors concerning parts that are used in our products.

Possible impacts on the functionality of our products, due to changes in functionality or obsolesce of a certain part, are constantly being evaluated in order to take the right measures in purchasing or within our hardware/software design.

Our general philosophy here is: We never discontinue a product as long as there is a demand for it.

Therefore, we have established a set of methods to fulfill our philosophy:

Avoiding strategies:

- Avoid changes by evaluating the longevity of parts during the design-in phase.

- Ensure the availability of equivalent second source parts.

- Stay in close contact with part vendors to be aware of roadmap strategies.

Change management in the rare event of an obsolete and non-replaceable part:

- Ensure long-term availability by stocking parts through last-time buy management according to product forecasts.

- Offer long-term frame contracts to customers.

Change management in case of functional changes:

- Avoid impacts on product functionality by choosing equivalent replacement parts.

- Avoid impacts on product functionality by compensating changes through HW redesign or backward-compatible SW maintenance.

- Provide early change notifications concerning functional relevant changes to our products.

Therefore, we refrain from providing detailed part-specific information within this manual, which can be subject to continuous changes, due to part maintenance for our products.

In order to receive reliable, up-to-date, and detailed information concerning parts used for our product, please contact our support team through the contact information given within this manual.

PHYTEC Documentation

PHYTEC will provide a variety of hardware and software documentation for all of our products. This includes any or all of the following:

- QS Guide: A short guide on how to set up and boot a phyCORE board along with brief information on building a BSP, the device tree, and accessing peripherals.

- Hardware Manual: A detailed description of the System on Module and accompanying carrier board.

- Yocto Guide: A comprehensive guide for the Yocto version the phyCORE uses. This guide contains an overview of Yocto; an introduction, installing and customizing the PHYTEC BSP; how to work with programs like Poky and Bitbake; and much more.

- BSP Manual: A manual specific to the BSP version of the phyCORE. Information such as how to build the BSP, booting, updating software, device tree, and accessing peripherals can be found here.

- Development Environment Guide: This guide shows how to work with the pre-programmed programs Eclipse and Qt Creator. It includes instructions for running demo projects for these programs on a phyCORE product. Information on how to set up a Linux host PC is also included.

- Pin Muxing Table: Starting in 2019, all phyCORE SOMs will have an accompanying pin table (in Excel format). This table will show the complete default signal path, from processor to carrier board. The default device tree muxing option will also be included. This gives a developer all the information needed in one location to make muxing changes and design options when developing a specialized carrier board or adapting a PHYTEC phyCORE SOM to an application.

On top of these standard manuals and guides, PHYTEC will also provide Product Change Notifications, Application Notes, and Technical Notes. These will be done on a case-by-case basis. All documentation can be found on the applicable download page of our products.

Conventions, Abbreviations, and Acronyms

This hardware manual describes the PCM-068 System on Module, referred to as phyCORE‑STM32MP15x, and the corresponding single-board computer PCM-939, the phyBOARD-Sargas STM32MP15x. The manual specifies phyCORE‑STM32MP15x and phyBOARD-Sargas's design and function. Precise specifications for the STMicroelectronics® STM32MP15x microcontrollers can be found in the enclosed Microcontroller Data Sheet/User's Manual.

Note

We refrain from providing detailed, part-specific information within this manual (due to part maintenance for our products), which can be subject to continuous changes. Please read the section Product Change Management and Information Regarding Parts Populated on the SOM / Carrier Board within the Preface.

Note

The BSP delivered with the phyCORE®-STM32MP15x usually includes drivers and/or software for controlling all components such as interfaces, memory, etc. Programming close to hardware at the register level is not necessary in most cases. For this reason, this manual contains no detailed description of the controller's registers or information relevant to software development. Please refer to the STM32MP157C Reference Manual, if such information is needed to connect customer-designed applications.

Conventions

The conventions used in this manual are as follows:

- Signals that are preceded by an "n", "/", or “#” character (e.g.: nRD, /RD, or #RD), or that have a dash on top of the signal name are designated as active low signals. That is, their active state is when they are driven low or are driving low.

- A "0" indicates a logic zero or low-level signal, while a "1" represents a logic one or high-level signal.

- The hex numbers given for addresses of I2C devices always represent the 7 MSB of the address byte. The correct value of the LSB which depends on the desired command (read (1), or write (0)) must be added to get the complete address byte. E.g. given address in this manual 0x41 => complete address byte = 0x83 to read from the device and 0x82 to write to the device

- Tables that describe jumper settings show the default position in bold,bluetext.

- Text in blue italic indicates a hyperlink within, or external to the document. Click these links to quickly jump to the applicable URL, part, chapter, table, or figure.

- References made to the phyCORE-Connector always refer to the high-density Samtec connector on the undersides of the phyCORE‑STM32MP15x System on Module.

Types of Signals

Different types of signals are brought out at the phyCORE-Connector. The following table lists the abbreviations used to specify the type of signal.

Signal Type | Description | Abbreviation |

|---|---|---|

Power | Supply voltage input | PWR_I |

Power | Supply voltage output | PWR_O |

Ref-Voltage | Reference voltage output | REF_O |

Input | Digital input | I |

Output | Digital output | O |

IO | Bidirectional input/output | I/O |

OC-Bidir PU | Open collector input/output with pull up | OC-BI |

OC-Output | Open collector output without pull up requires an external pull up | OC |

OD-Output | Open-drain output without pull up requires an external pull up | OD |

5V Input PD | 5 V tolerant input with a pull-down | 5V_PD |

LVDS Input | Differential line pairs 100 Ohm LVDS level input | LVDS_I |

LVDS Output | Differential line pairs 100 Ohm LVDS level output | LVDS_O |

TMDS Output | Differential line pairs 100 Ohm TMDS level output | TMDS_O |

USB IO | Differential line pairs 90 Ohm USB level bidirectional input/output | USB_I/O |

ETHERNET Input | Differential line pairs 100 Ohm Ethernet level input | ETH_I |

ETHERNET Output | Differential line pairs 100 Ohm Ethernet level output | ETH_O |

ETHERNET IO | Differential line pairs 100 Ohm Ethernet level bidirectional input/output | ETH_I/O |

MIPI DSI Output | Differential line pairs 100 Ohm MIPI DSI level output | DSI_O |

Abbreviations and Acronyms

Many acronyms and abbreviations are used throughout this manual. Use this table to navigate unfamiliar terms used in this document.

| Abbreviation | Definition |

|---|---|

BSP | Board Support Package (Software delivered with the Development Kit including an operating system (Windows, or Linux) preinstalled on the module and Development Tools). |

CB | Carrier Board; used in reference to the phyCORE Development Kit Carrier Board. |

DFF | D flip-flop. |

EMB | External memory bus. |

EMI | Electromagnetic Interference. |

GPI | General-purpose input. |

GPIO | General-purpose input and output. |

GPO | General-purpose output. |

IRAM | Internal RAM; the internal static RAM on the STMicroelectronics® STM32MP15x microcontroller. |

J | Solder jumpers; these types of jumpers require solder equipment to remove and place. |

JP | Solderless jumpers; these types of jumpers can be removed and placed by hand with no special tools. |

PCB | Printed circuit board. |

PDI | PHYTEC Display Interface; defined to connect PHYTEC display adapter boards, or custom adapters |

PEB | PHYTEC Extension Board |

PMIC | Power management IC |

PoE | Power over Ethernet |

POR | Power-on reset |

RTC | Real-time clock. |

SMT | Surface mount technology. |

SOM | System on Module; used in reference to the PCM-068 /phyCORE®-STM32MP15x module |

Sx | User button Sx (e.g. S1, S2, etc.) used in reference to the available user buttons, or DIP-Switches on the carrier board. |

Sx_y | Switch y of DIP-Switch Sx; used in reference to the DIP-Switch on the carrier board. |

phyCORE‑STM32MP15x Introduction

The phyCORE‑STM32MP15x belongs to PHYTEC’s phyCORE System on Module family. The phyCORE SOMs represent the continuous development of the PHYTEC System on Module technology. Like its mini-, micro-, and nano MODUL predecessors, phyCORE boards integrate all core elements of a microcontroller system on a sub-miniature board and are designed in a manner that ensures their easy expansion and embedding in peripheral hardware developments.

Independent research indicates approximately 70 % of all EMI (Electro-Magnetic Interference) problems are caused by insufficient supply voltage grounding of electronic components in high-frequency environments. The phyCORE board design features an increased pin package, which provides for the dedication of approximately 20 % of all connector pinson the phyCORE boards to Ground. This improves EMI and EMC characteristics and makes it easier to design complex applications meeting EMI and EMC guidelines using phyCORE boards, even in high-noise environments.

phyCORE boards achieve their small size through modern SMD technology and multi-layer design. In accordance with the complexity of the module, 0201-packaged SMT components and laser-drilled microvias are used on the boards, providing phyCORE users with access to this cutting-edge miniaturization technology for integration into their own design.

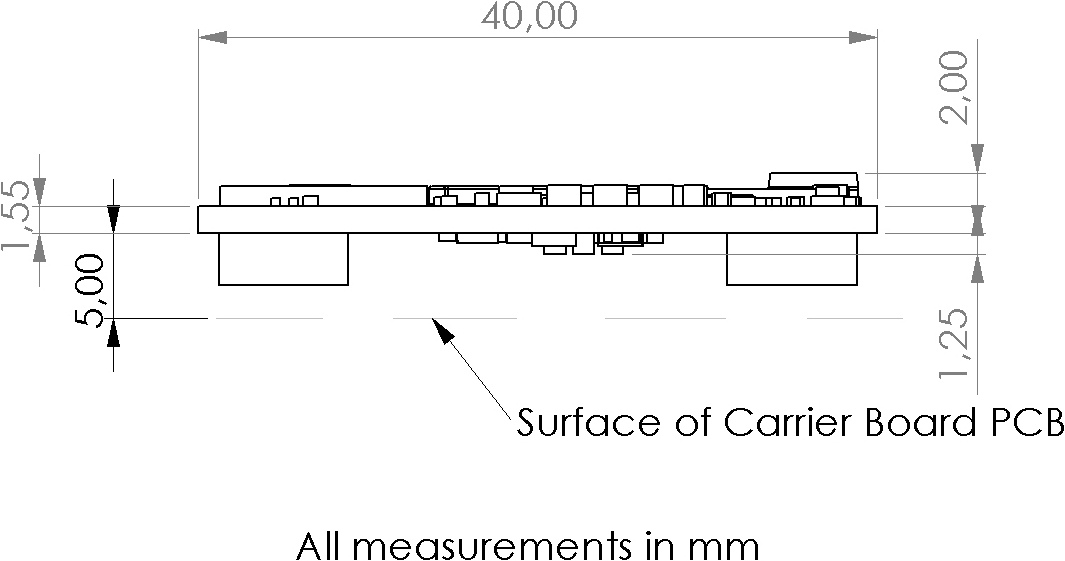

The phyCORE‑STM32MP15x is a sub-miniature (40 mm x 44 mm) insert-ready System on Module populated with the STMicroelectronics® STM32MP15x microcontroller. Its universal design enables its insertion in a wide range of embedded applications. All controller signals and ports extend from the controller to high-density pitch, or surface mount technology (SMT) connectors (all pitch 0.5 mm) aligning two sides of the board, allowing it to be plugged or soldered into any target application like a "big chip".

The descriptions in this manual are based on the STMicroelectronics STM32MP157C. No description of compatible microcontroller derivative functions is included as such functions are not relevant for the basic functioning of the phyCORE‑STM32MP15x. Precise specifications for the controller populating the board can be found in the applicable controller technical reference manual or datasheet.

Note

- Most of the controller pins have multiple multiplexed functions. As most of these pins are connected directly to the phyCORE-Connector, the alternative functions are available by using the STM32MP15x's pin muxing options. However, the following list of features is in regard to the specification of the phyCORE‑STM32MP15x and the functions defined therein. Therefore, theindicatednumberofcertaininterfaces,CSsignals,etc.isperhapssmallerthanavailableonthecontroller. Please refer to the STM32MP157C Reference Manual to learn more about alternative functions. In order to utilize a specific pin's alternative function, the corresponding registers and the device tree must be configured within the appropriate driver of the BSP.

Tip

- STMicroelectronics provides software for pin muxing. For further information about the pin muxing tool, refer to STM32CubeMX.

phyCORE‑STM32MP15x Features

The phyCORE‑STM32MP15x offers the following features:

- Insert-ready, sub-miniature (44 mm x 40 mm) System on Module (SOM) sub-assembly in low EMI design, achieved through advanced SMT technology

Populated with the STMicroelectronics® STM32MP157C[1]microcontroller (TFBGA361 packaging)

- Up to 2 ARM-Cortex-A7 cores (clock frequency up to 800 MHz) + ARM-Cortex-M4 core up to 209 MHz

- Boot from different memory devices (SD card, QSPI NOR-Flash, NAND-Flash, eMMC)

- Controller signals and ports extend to two high-density pitch (0.5 mm) Samtec connectors aligning two sides of the board, enabling the phyCORE‑STM32MP15x to be plugged into any target applications like a "big chip"

- Single supply voltage of +5.0 V with on-board power management

- All controller-required supplies are generated on-board

- Improved interference safety achieved through multi-layer PCB technology and dedicated ground pins

256 MB (up to 1 GB[2]) 32-bit wide DDR3L RAM

- 4 GB (up to 32 GB[2]) onboard eMMC, or 128 MB (up to 1 GB[2]) onboard SLC NAND flash

- 4 MB (up to 16 MB[2])Quad SPI NOR flash (bootable)

- 4 kB (up to 32 kB[2]) I2C EEPROM

- 4x UART interfaces

- 2x High-speed USB 2.0 interfaces (1 x USB host and 1 x USB OTG)

- 1x 10/100/1000 Mbit/s Ethernet interface. Either with Ethernet transceiver on the phyCORE‑STM32MP15x, allowing for direct connection to an existing Ethernet network, or without an onboard transceiver and provision of the RGMII signals at TTL-level (10/100/1000 Mbit/s) at the phyCORE‑Connector instead[1]

- 2x I2C interfaces

- 2x SPI interfaces (NAND/QSPI)

- 1x CAN FD interface

- 1x MIPI DSI interface

- 1x Parallel 18-bit RGB display interface with HDMI-CEC

- 1x 10-bit parallel camera interface

- 1x SAI Audio interface

- 1x MDIO interface

3x Secure Digital I/O MultiMediaCard interfaces (SDMMC) up to 8-bit (SD / eMMC / SDIO)

Several dedicated GPIOs[3]

- Several AD conversion and filter inputs digital (DFSDM)

- 2x 12-bit DAC outputs

- 1x JTAG/Serial-wire debug interface with trace ports and debug trigger I/Os

- I2C Real-Time Clock[1] with a very low-power operation, independent from CPU-supply

- Power Management IC (PMIC)

- Available for different temperature grades (Product Temperature Grades)

Warning

Samtec connectors guarantee optimal connection and proper insertion of the phyCORE‑STM32MP15x. Please make sure that the STM32MP15x module is fully plugged into the mating connectors of the carrier board. Otherwise, individual signals may have bad contact or no contact at all.

| 1. | Please refer to the order options described in the Preface, or contact PHYTEC for more information about |

| 2. | The maximum memory size listed is as of the printing of this manual. |

| 3. | Almost every controller port which connects directly to the phyCORE-Connector may be used |

phyCORE‑STM32MP15x Block Diagram

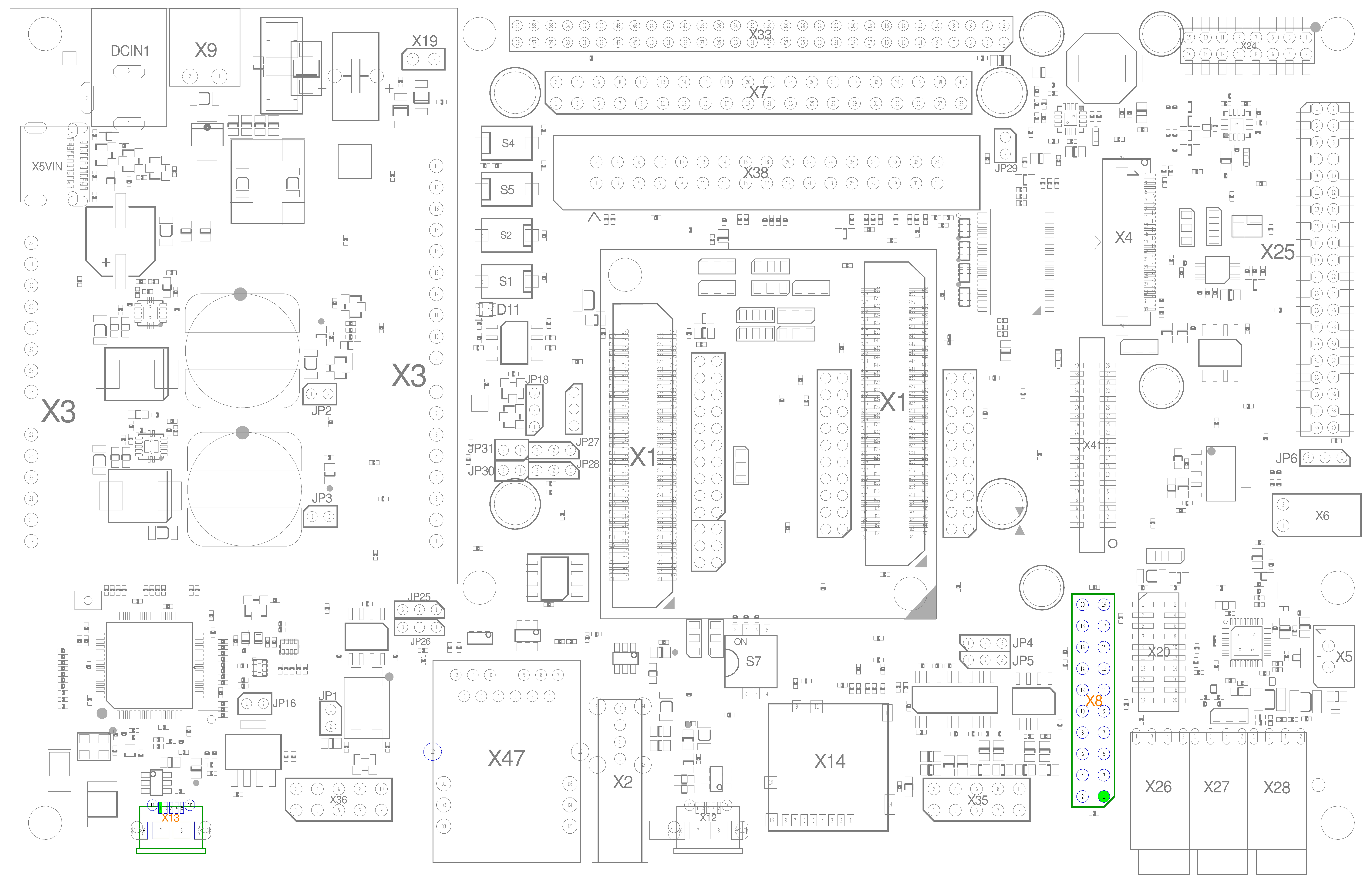

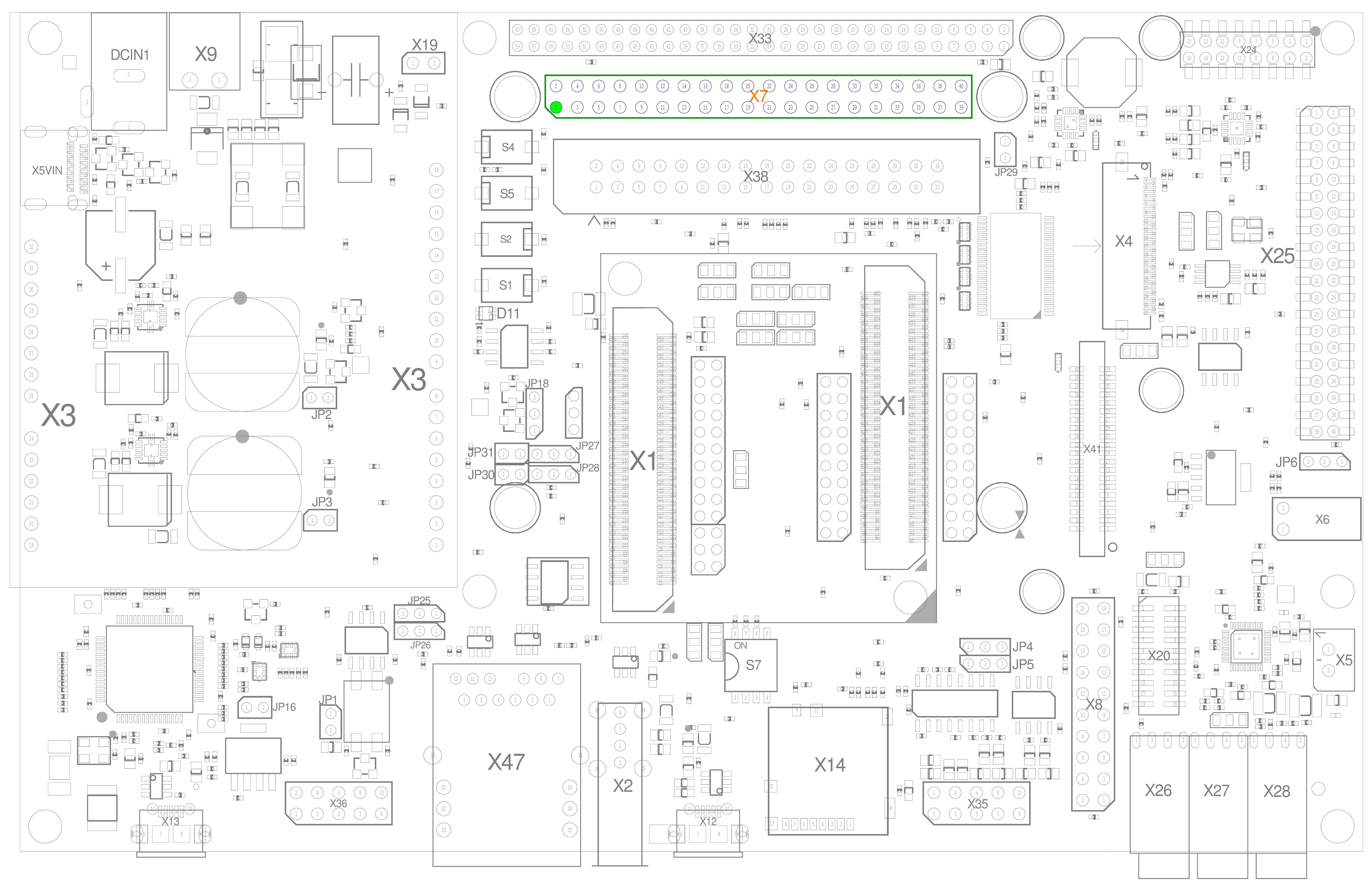

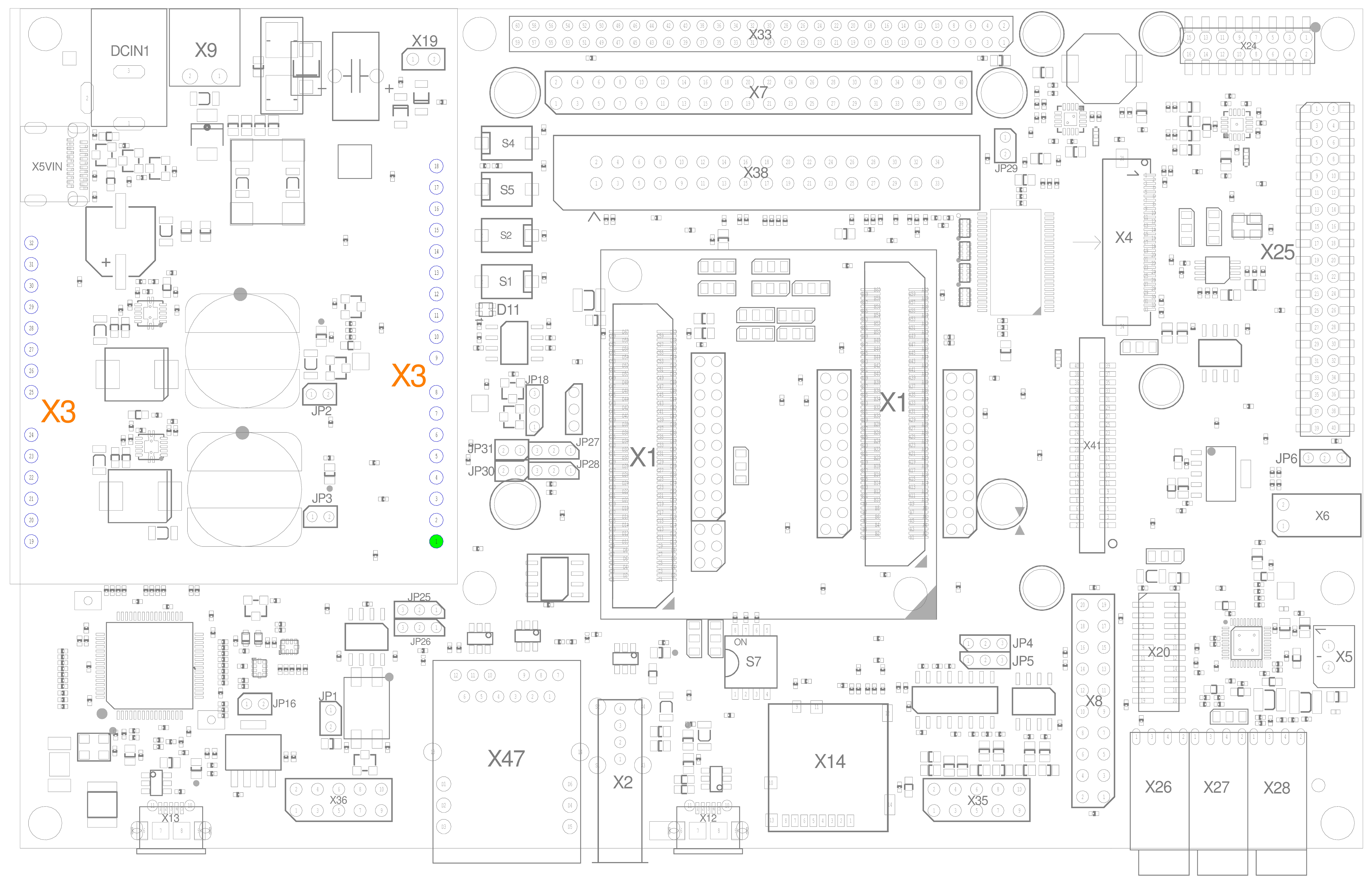

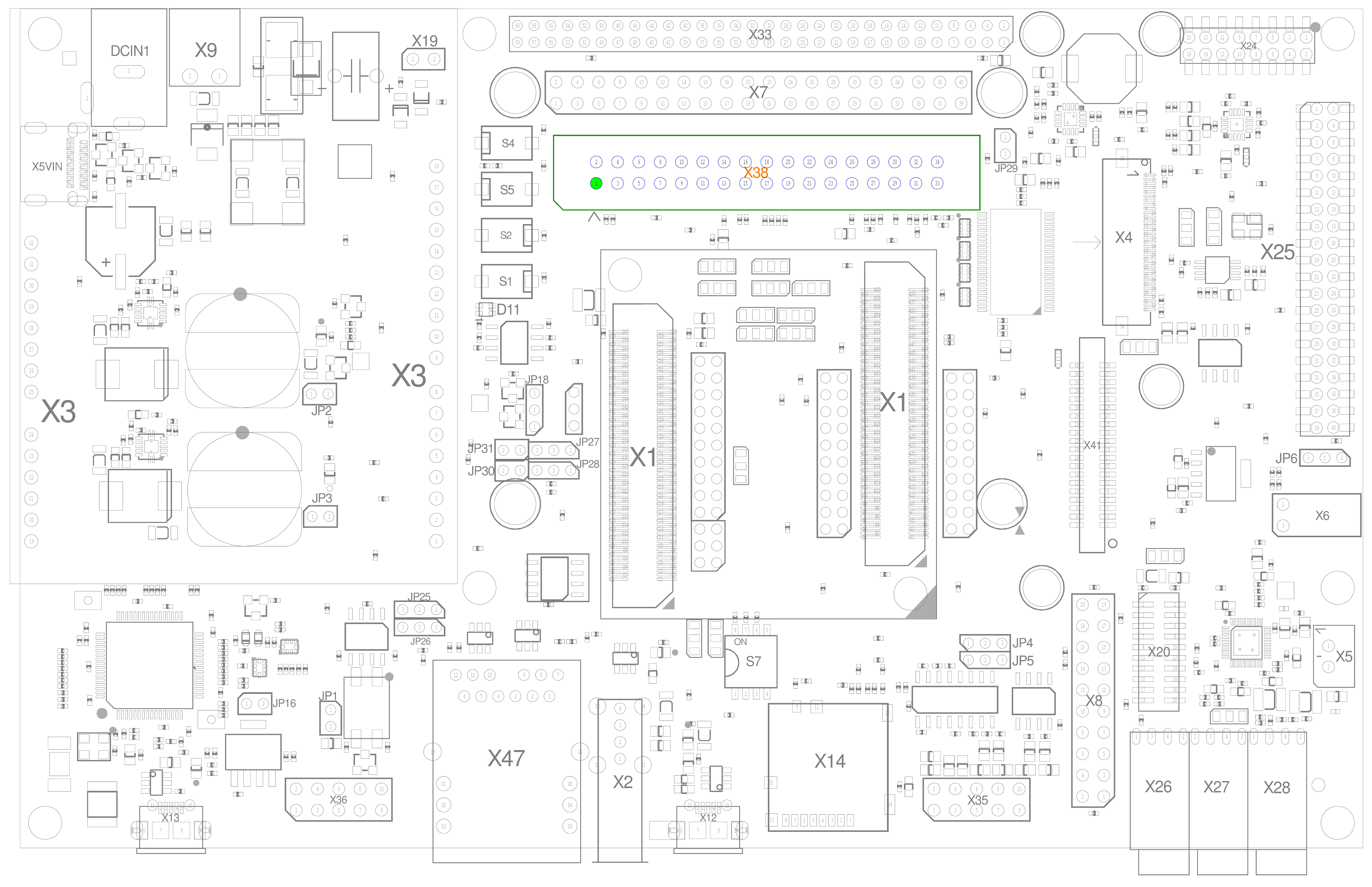

phyCORE‑STM32MP15x Component Placement

phyCORE‑STM32MP15x Minimum Operating Requirements

Warning

We recommend connecting all available +5 V input pins to the power supply system on a custom carrier board housing the phyCORE‑STM32MP15x and, at minimum, the matching number of GND pins neighboring the +5 V pins. In addition, proper implementation of the phyCORE‑STM32MP15x module into a target application also requires connecting all GND pins. Refer to sectionPower for more information.

Pin Description

Warning

Module connections must not exceed their expressed maximum voltage or current. Maximum signal input values are indicated in the corresponding controller manuals/datasheets. As damage from improper connections varies according to use and application, it is the user's responsibility to take appropriate safety measures to ensure that the module connections are protected from overloading through connected peripherals.

As the imagePinout of the phyCORE-Connector indicates, all controller signals selected extend to surface mount technology (SMT) connectors (0.5 mm). These connectors line two sides of the module (referred to as phyCORE-Connectors). This enables the phyCORE‑STM32MP15x to be plugged into any target application like a "big chip".

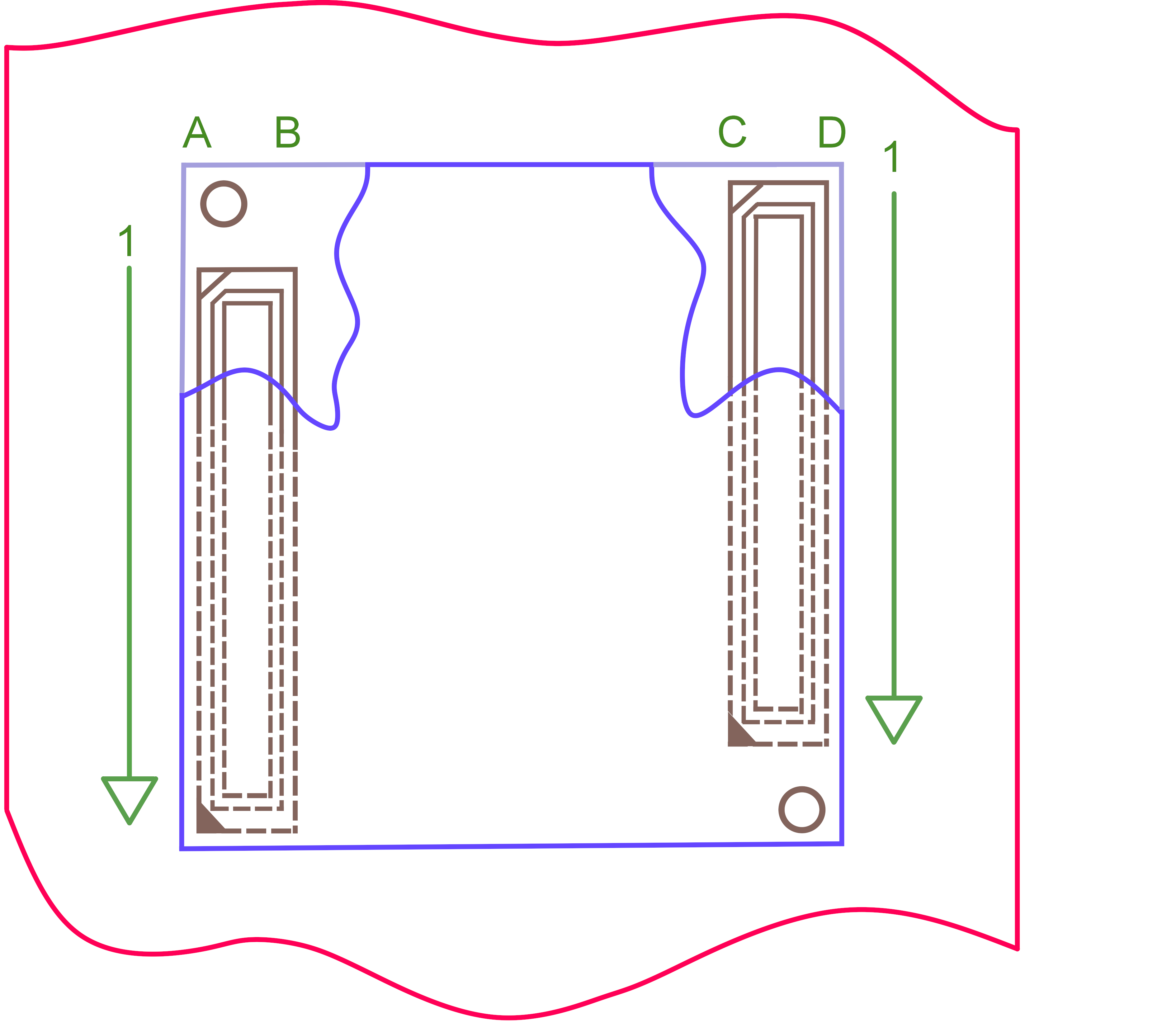

The numbered scheme for the phyCORE‑Connector is based on a two-dimensional matrix in which column positions are identified by a letter and row positions by a number. The pin numbering values increase as you move across the board from left to right. The numbered matrix can be aligned with the phyCORE‑STM32MP15x (viewed from above; phyCORE‑Connector pointing down) or with the socket of the corresponding phyCORE carrier board/user target circuitry. The upper left-hand corner of the numbered matrix (pin X1A1) is covered by the corner of the phyCORE‑STM32MP15x. The numbering scheme is always in relation to the PCB as viewed from above, even if all connector contacts extend to the bottom of the module.

The numbering scheme is consistent for both the module's phyCORE‑Connector as well as the mating connector on the phyCORE carrier board or target application. This reduces the risk of pin identification errors considerably.

Since the pins are precisely defined according to the numbered matrix described above, the phyCORE‑Connector is usually assigned a single designator for its position (X1 for example). This way, the phyCORE‑Connector comprises a single, logical unit regardless of the fact that it could consist of more than one physically socketed connector.

The following figure illustrates the numbered matrix system. It shows a phyCORE‑STM32MP15x with SMT phyCORE‑Connectors on its underside (defined with dotted lines) as it would be mounted on a carrier board. In order to facilitate understanding of the pin assignment scheme, the diagram presents a cross-view of the phyCORE module showing these phyCORE‑Connectors mounted on the underside of the module’s PCB.

The Pinout table below provides an overview of the pinout of the phyCORE‑Connector X1 with signal names and descriptions specific to the phyCORE‑STM32MP15x. It also provides the appropriate signal level interface voltages listed in the (Signal) Level column, (Signal) Type, as well as information regarding the controller pin. The signal type includes also information about the signal direction.[4]A description of the signal types can be found in the table Signal Types.

In addition to the table in this manual PHYTEC provides a complete pinout table for the phyCORE‑STM32MP15x and PHYTEC carrier board as a downloadable Excel sheet (phyCORE-STM32MP1_Pinout_Table.A0_public.xls). This table includes signal names, pin muxing paths, and descriptions specific to the phyCORE‑STM32MP15x and the phyBOARD‑Sargas. It also provides the appropriate signal type and a functional grouping of the signals. The signal type also includes information about the signal direction. A table describing the signal types can be found on a second tab sheet in the Excel file.

| 4. | The specified direction indicated refers to the standard phyCORE use of the pin. |

Warning

- The STMicroelectronics® STM32MP15x is a multi-voltage operated microcontroller and, as such, special attention should be paid to the interface voltage levels to avoid unintentional damage to the microcontroller and other on-board components. Please refer to the STMicroelectronics STM32MP15x Reference Manual for details on the functions and features of controller signals and port pins.

- The phyCORE‑STM32MP15x has three dedicated boot signals which are brought out on the phyCORE-Connector and are used to configure specific boot options. Please make sure that these signals are not driven by any device on the baseboard during a reset. The signals which may affect the boot configuration are described in section Boot Mode Selection.

- It is necessary to avoid voltages at the IO pins of the phyCORE‑STM32MP15x which are sourced from the supply voltage of peripheral devices attached to the SOM during power-up or power-down. These voltages can cause a current flow into the controller, especially if peripheral devices attached to the interfaces of the STM32MP15x are supposed to be powered while the phyCORE‑STM32MP15x is in suspend mode or turned off.To avoid this, bus switches either supplied by VDD (3.3 V) on the phyCORE side or having their output enabled to the SOM controlled by the VDD signal, must be used (seeSupply Voltage for External Logic).

Tips

- Most of the controller pins have multiple, multiplexed functions. As most of these pins are connected directly to the phyCORE-Connector, the alternative functions are available by using the STM32MP15x's pin muxing options. Signal names and descriptions in the accompanying table, however, are in regard to the specification of the phyCORE‑STM32MP15x and the functions defined. Please refer to the STMicroelectronics STM32MP15x Reference Manual or the schematic to get to know about alternative functions. In order to utilize a specific pin's alternative function, the corresponding registers must be configured within the appropriate driver of the BSP.

- The following tables describe the full set of signals available at the phyCORE‑Connector according to the phyCORE‑STM32MP15x specification. However, the availability of some interfaces is order-specific (e.g. SDMMC2, RGMII). This means some signals might not be available on your module.

- If the phyCORE‑STM32MP15x is delivered with the carrier board, the pin muxing might be changed within the appropriate BSP in order to support all features of the carrier board. If so, information on the differences from the pinout given in the following tables can be found in the carrier board's documentation (seephyCORE‑STM32MP15x on the phyBOARD-Sargas SBC).

| Pin No. | Signal Name | Level | Type | Pin Name | BGA361-Pad | Description |

|---|---|---|---|---|---|---|

| A1 | X_MIPI_DSI_CLKN | 1.2 V | DSI_O | DSI_CKN | A16 | MIPI DSI clock negative output |

| A2 | X_MIPI_DSI_CLKP | 1.2 V | DSI_O | DSI_CKP | B16 | MIPI DSI clock positive output |

| A3 | GND | |||||

| A4 | X_MIPI_DSI_DATA0N | 1.2 V | DSI_O | DSI_D0N | B15 | MIPI DSI data0 negative output |

| A5 | X_MIPI_DSI_DATA0P | 1.2 V | DSI_O | DSI_D0P | C15 | MIPI DSI data0 positive output |

| A6 | GND | |||||

| A7 | X_MIPI_DSI_DATA1N | 1.2 V | DSI_O | DSI_D1N | A17 | MIPI DSI data1 negative output |

| A8 | X_MIPI_DSI_DATA1P | 1.2 V | DSI_O | DSI_D1P | B17 | MIPI DSI data1 positive output |

| A9 | X_MIPI_DSIHOST_TE/PD13 | 3.3 V | I | PD13 | AA19 | MIPI DSI tearing effect input |

| A10 | GND | |||||

| A11 | X_SDMMC2_DATA0/PB14 | 3.3 V | I/O | PB14 | C13 | SD/SDIO/eMMC card data line 0 |

| A12 | X_SDMMC2_DATA1/PB15 | 3.3 V | I/O | PB15 | B12 | SD/SDIO/eMMC card data line 1 |

| A13 | X_SDMMC2_DATA2/PB3 | 3.3 V | I/O | PB3 | A11 | SD/SDIO/eMMC card data line 2 |

| A14 | X_SDMMC2_DATA3/PB4 | 3.3 V | I/O | PB4 | B13 | SD/SDIO/eMMC card data line 3 |

| A15 | X_SDMMC2_DATA4/PA8 | 3.3 V | I/O | PA8 | A13 | SD/SDIO/eMMC card data line 4 |

| A16 | X_SDMMC2_DATA5/PA9 | 3.3 V | I/O | PA9 | A8 | SD/SDIO/eMMC card data line 5 |

| A17 | X_SDMMC2_DATA6/PC6 | 3.3 V | I/O | PC6 | B14 | SD/SDIO/eMMC card data line 6 |

| A18 | X_SDMMC2_DATA7/PD3 | 3.3 V | I/O | PD3 | D14 | SD/SDIO/eMMC card data line 7 |

| A19 | GND | |||||

| A20 | X_SDMMC2_CMD/PG6 | 3.3 V | I/O | PG6 | A10 | SD/SDIO/eMMC card bidirectional command/response signal |

| A21 | X_SDMMC2_CLK/PE3 | 3.3 V | O | PE3 | C9 | SD/SDIO/eMMC card clock |

| A22 | GND | |||||

| A23 | X_SDMMC3_D0/PF0 | 3.3 V | I/O | PF0 | D8 | SDIO SDMMC3 interface |

| A24 | X_SDMMC3_D1/PF4 | 3.3 V | I/O | PF4 | D9 | |

| A25 | X_SDMMC3_D2/PF5 | 3.3 V | I/O | PF5 | D7 | |

| A26 | X_SDMMC3_D3/PD7 | 3.3 V | I/O | PD7 | D10 | |

| A27 | X_SDMMC3_CMD/PF1 | 3.3 V | I/O | PF1 | A5 | |

| A28 | X_SDMMC3_CK/PG15 | 3.3 V | O | PG15 | B7 | |

| A29 | GND | |||||

| A30 | X_DCMI_HSYNC/PH8 | 3.3 V | I | PH8 | D5 | DCMI Horizontal synchronization / Data valid |

| A31 | X_DCMI_VSYNC/PB7 | 3.3 V | I | PB7 | D11 | DCMI Vertical synchronization |

| A32 | X_DCMI_PIXCLK/PA6 | 3.3 V | I | PA6 | AC8 | DCM Pixel clock |

| A33 | GND | |||||

| A34 | X_DCMI_DATA5/PI4 | 3.3 V | I | PI4 | E4 | DCMI data5 |

| A35 | X_DCMI_DATA6/PE5 | 3.3 V | I | PE5 | C11 | DCMI data6 |

| A36 | X_DCMI_DATA7/PI7 | 3.3 V | I | PI7 | F2 | DCMI data7 |

| A37 | X_DCMI_DATA8/PI1 | 3.3 V | I | PI1 | E3 | DCMI data8 |

| A38 | X_DCMI_DATA9/PH7 | 3.3 V | I | PH7 | W4 | DCMI data9 |

| A39 | GND | |||||

| A40 | X_LCD_R2/PC10 | 3.3 V | O | PC10 | D15 | LCD data red2 |

| A41 | X_LCD_R3/PB0 | 3.3 V | O | PB0 | AB6 | LCD data red3 |

| A42 | X_LCD_R4/PH10 | 3.3 V | O | PH10 | C2 | LCD data red4 |

| A43 | X_LCD_R5/PH11 | 3.3 V | O | PH11 | C4 | LCD data red5 |

| A44 | X_LCD_R6/PH12 | 3.3 V | O | PH12 | B2 | LCD data red6 |

| A45 | X_LCD_R7/PE15 | 3.3 V | O | PE15 | D3 | LCD data red7 |

| A46 | GND | |||||

| A47 | X_LCD_G2/PH13 | 3.3 V | O | PH13 | D1 | LCD data green2 |

| A48 | X_LCD_G3/PE11 | 3.3 V | O | PE11 | A4 | LCD data green3 |

| A49 | X_LCD_G4/PH15 | 3.3 V | O | PH15 | B1 | LCD data green4 |

| A50 | X_LCD_G5/PH4 | 3.3 V | O | PH4 | B3 | LCD data green5 |

| A51 | X_LCD_G6/PI11 | 3.3 V | O | PI11 | P4 | LCD data green6 |

| A52 | X_LCD_G7/PI2 | 3.3 V | O | PI2 | E2 | LCD data green7 |

| A53 | GND | |||||

| A54 | X_UART4_RX/PB2 | 3.3 V | I | PB2 | Y16 | UART4 serial data receive signal |

| A55 | X_USART1_TX/PZ7 | 3.3 V | O | PZ7 | J3 | USART1 serial data transmit signal |

| A56 | X_SPI16_MOSI/PZ2 | 3.3 V | I/O | PZ2 | Z2 | SPI1 master output/slave input |

| A57 | X_SPI16_NSS/PZ3 | 3.3 V | I/O | PZ3 | G4 | SPI1 slave select (active low) |

| A58 | X_LCD_BL_PWM/PI0 | 3.3 V | O | PI0 | C1 | PWM output (e.g. to control the brightness) |

| A59 | X_PI3 | 3.3 V | I/O | PI3 | E1 | GPIO PI3 (LCD Touch-IRQn in) |

| A60 | X_PD9 | 3.3 V | I/O | PD9 | K1 | GPIO PD9 (LCD Reset out) |

| Pin No. | Signal Name | Level | Type | Pin Name | BGA361-Pad | Description |

|---|---|---|---|---|---|---|

| B1 | GND | |||||

| B2 | X_JTAG_nTRST | 3.3 V | I | NJTRST | B19 | JTAG test reset (active low) |

| B3 | X_JTAG_TDI | 3.3 V | I | JTDI | A20 | JTAG test data input |

| B4 | X_JTAG_TMS/SWDIO | 3.3 V | I / I/O | JTMS-SWDIO | C20 | JTAG test mode select / Serial wire data in/out |

| B5 | X_JTAG_TCK/SWCLK | 3.3 V | I | JTCK-SWCLK | B20 | JTAG test clock / Serial wire clock |

| B6 | X_JTAG_TDO/TRACESWO | 3.3 V | O | JTDO-TRACESWO | A19 | JTAG test data output / Trace asynchronous data out |

| B7 | GND | |||||

| B8 | X_SDMMC1_D0/PC8 | 3.3 V | I/O | PC8 | D18 | SDMMC1 interface normally used for external SDCard (boot option) |

| B9 | X_SDMMC1_D1/PC9 | 3.3 V | I/O | PC9 | D17 | |

| B10 | X_SDMMC1_D2/PE6 | 3.3 V | I/O | PE6 | C10 | |

| B11 | X_SDMMC1_D3/PC11 | 3.3 V | I/O | PC11 | D16 | |

| B12 | X_SDMMC1_CMD/PD2 | 3.3 V | I/O | PD2 | D12 | |

| B13 | GND | |||||

| B14 | X_SDMMC1_CK/PC12 | 3.3 V | O | PC12 | D13 | SDMMC1 interface clock out |

| B15 | X_SDMMC1_CKIN/PE4 | 3.3 V | I | PE4 | D19 | SDMMC1 clock feedback in |

| B16 | X_SDMMC1_CDIR/PB9 | 3.3 V | O | PB9 | B10 | UART4 TXD |

| B17 | X_SDMMC1_D0DIR/PF2 | 3.3 V | O | PF2 | A14 | SDMMC1 dat0 direction out |

| B18 | X_SDMMC1_D123DIR/PE14 | 3.3 V | O | PE14 | C6 | SDMMC1 dat123 direction out |

| B19 | GND | |||||

| B20 | X_FMC_DATA0/PD14 | 3.3 V | I/O | PD14 | L3 | Address / Data 0 |

| B21 | X_FMC_DATA1/PD15 | 3.3 V | I/O | PD15 | J2 | Address / Data 1 |

| B22 | X_FMC_DATA2/PD0 | 3.3 V | I/O | PD0 | B8 | Address / Data 2 |

| B23 | X_FMC_DATA3/PD1 | 3.3 V | I/O | PD1 | B9 | Address / Data 3 |

| B24 | X_FMC_DATA4/PE7 | 3.3 V | I/O | PE7 | AA11 | Address / Data 4 |

| B25 | X_FMC_DATA5/PE8 | 3.3 V | I/O | PE8 | AC13 | Address / Data 5 |

| B26 | X_FMC_DATA6/PE9 | 3.3 V | I/O | PE9 | AA9 | Address / Data 6 |

| B27 | X_FMC_DATA7/PE10 | 3.3 V | I/O | PE10 | Y15 | Address / Data 7 |

| B28 | GND | |||||

| B29 | X_FMC_nWAIT/PD6 | 3.3 V | I | PD6 | D2 | Input for external ready/busy (wait) signal (active low) |

| B30 | X_FMC_nOE/PD4 | 3.3 V | O | PD4 | B6 | Output enable/ Read enable (active low) |

| B31 | X_FMC_nCE/PG9 | 3.3 V | O | PG9 | Y13 | Chip select 1 |

| B32 | X_FMC_CLE/PD11 | 3.3 V | O | PD11 | AC10 | Command latch enable |

| B33 | X_FMC_ALE/PD12 | 3.3 V | O | PD12 | Y18 | Address latch enable |

| B34 | X_FMC_nNWE/PD5 | 3.3 V | O | PD5 | A7 | Write enable (active low) |

| B35 | GND | |||||

| B36 | X_DCMI_DATA0/PH9 | 3.3 V | I | PH9 | C5 | DCMI data0 |

| B37 | X_DCMI_DATA1/PC7 | 3.3 V | I | PC7 | B11 | DCMI data1 |

| B38 | X_DCMI_DATA2/PE0 | 3.3 V | I | PE0 | D6 | DCMI data2 |

| B39 | X_DCMI_DATA3/PE1 | 3.3 V | I | PE1 | C8 | DCMI data3 |

| B40 | X_DCMI_DATA4/PH14 | 3.3 V | I | PH14 | C3 | DCMI data4 |

| B41 | GND | |||||

| B42 | X_LCD_B2/PG10 | 3.3 V | O | PG10 | AB11 | LCD data blue2 |

| B43 | X_LCD_B3/PG11 | 3.3 V | O | PG11 | Y7 | LCD data blue3 |

| B44 | X_LCD_B4/PE12 | 3.3 V | O | PE12 | B4 | LCD data blue4 |

| B45 | X_LCD_B5/PI5 | 3.3 V | O | PI5 | F3 | LCD data blue5 |

| B46 | X_LCD_B6/PB8 | 3.3 V | O | PB8 | AB10 | LCD data blue6 |

| B47 | X_LCD_B7/PD8 | 3.3 V | O | PD8 | K3 | LCD data blue7 |

| B48 | GND | |||||

| B49 | X_LCD_HSYNC/PI10 | 3.3 V | O | PI10 | T1 | LCD horizontal sync |

| B50 | X_LCD_VSYNC/PI9 | 3.3 V | O | PI9 | H4 | LCD vertical sync |

| B51 | X_LCD_DE/PE13 | 3.3 V | O | PE13 | A3 | LCD data enable |

| B52 | X_LCD_CLK/PG7 | 3.3 V | O | PG7 | AC14 | LCD clock |

| B53 | GND | |||||

| B54 | X_SPI16_SCK/PZ0 | 3.3 V | I/O | PZ0 | G3 | SPI1 clock signal |

| B55 | X_USART1_RX/PZ6 | 3.3 V | I | PZ6 | H1 | USART1 RXD serial data receive signal |

| B56 | X_SPI16_MISO/PZ1 | 3.3 V | I/O | PZ1 | G1 | SPI1 master input/slave output |

| B57 | X_SPI1_MOSI/PB5 | 3.3 V | I | PB5 | Y8 | CAN FD2 serial data receive signal |

| B58 | X_SPI1_NSS/PA15 | 3.3 V | I/O | PA15 | C19 | HDMI-CEC |

| B59 | GND | |||||

| B60 | X_PI8 | 3.3 V | I/O | PI8 | L4 | GPIO PI8 |

| Pin No. | Signal Name | Level | Type | Pin Name | BGA361-Pad | Description |

|---|---|---|---|---|---|---|

| C1 | X_FDCAN1_RX/PA11 | 3.3 V | I | PA11 | AA18 | CAN FD1 serial data receive signal |

| C2 | X_FDCAN1_TX/PA12 | 3.3 V | O | PA12 | AB19 | CAN FD1 serial data transmit signal |

| C3 | GND | |||||

| C4 | X_QSPI_BK1_DATA0/PF8 | 3.3 V | I/O | PF8 | AC11 | QSPI Bidirectional IO0 |

| C5 | X_QSPI_BK1_DATA1/PF9 | 3.3 V | I/O | PF9 | AA14 | QSPI Bidirectional IO1 |

| C6 | X_QSPI_BK1_DATA2/PF7 | 3.3 V | I/O | PF7 | AB12 | QSPI Bidirectional IO2 |

| C7 | X_QSPI_BK1_DATA3/PF6 | 3.3 V | I/O | PF6 | AA13 | QSPI Bidirectional IO3 |

| C8 | X_QSPI_BK1_nCS/PB6 | 3.3 V | O | PB6 | Y14 | QSPI chip select for bank 1 (low active) |

| C9 | X_QSPI_CLK/PF10 | 3.3 V | O | PF10 | Y12 | QSPI clock signal |

| C10 | GND | |||||

| C11 | X_ADC1_INN1 | 0 V - VREF | ANA_I | ANA0 | U3 | ADC1 IN1- |

| C12 | X_ADC1_INP1 | 0 V - VREF | ANA_I | ANA1 | U4 | ADC1 IN1+ |

| C13 | X_ADC1_INN2/PF12 | 0 V - VREF | ANA_I | PF12 | Y9 | ADC1 IN2- |

| C14 | X_PVD_IN/ADC1_INN15/PA3 | 0 V - VREF | ANA_I | PA3 | U2 | ADC1 IN15- |

| C15 | VREF | 1.8 V - VDDA | PWR_I | R4 | Analog Reference in/out | |

| C16 | X_DACOUT1/PA4 | 0 V - VREF | ANA_O | PA4 | V4 | DAC OUT1 |

| C17 | X_DACOUT2/PA5 | 0 V - VREF | ANA_O | PA5 | V3 | DAC OUT2 |

| C18 | GND | |||||

| C19 | X_BOOT0 | 3.3 V | 5V_PD | BOOT0 | N1 | BOOT0 config in |

| C20 | X_BOOT1 | 3.3 V | 5V_PD | BOOT1 | N4 | BOOT1 config in |

| C21 | X_BOOT2 | 3.3 V | 5V_PD | BOOT2 | M2 | BOOT2 config in |

| C22 | GND | |||||

| C23 | X_DFSDM1_DATIN0/PG0 | 3.3 V | I | PG0 | AC2 | DFSDM1 data0 in |

| C24 | X_DFSDM1_DATIN1/PC3 | 3.3 V | I | PC3 | W2 | DFSDM1 data1 in |

| C25 | X_DFSDM1_DATIN3/PF13 | 3.3 V | I | PF13 | Y5 | DFSDM1 data2 in |

| C26 | X_DFSDM1_CKIN1/PG3 | 3.3 V | I | PG3 | T4 | DFSDM1 clock in |

| C27 | X_DFSDM1_CKOUT/PD10 | 3.3 V | O | PD10 | B5 | DFSDM1 clock out |

| C28 | GND | |||||

| C29 | X_ETH1_RGMII_RXD0/PC4 | 3.3 V | I | PC4 | AC7 | ETH1 RGMII receive data 0 |

| C30 | X_ETH1_RGMII_RXD1/PC5 | 3.3 V | I | PC5 | AB7 | ETH1 RGMII receive data 1 |

| C31 | X_ETH1_RGMII_RXD2/PH6 | 3.3 V | I | PH6 | Y11 | ETH1 RGMII receive data 2 |

| C32 | X_ETH1_RGMII_RXD3/PB1 | 3.3 V | I | PB1 | AA7 | ETH1 RGMII receive data 3 |

| C33 | X_ETH1_RGMII_RX_CTL/PA7 | 3.3 V | I | PA7 | AB8 | ETH1 RGMII receive control (RX_DV + RX_ER) |

| C34 | X_ETH1_RGMII_RX_CLK/PA1 | 3.3 V | I | PA1 | AA4 | ETH1 RGMII receive clock |

| C35 | GND | |||||

| C36 | X_ETH1_RGMII_TXD0/PG13 | 3.3 V | O | PG13 | AA2 | ETH1 RGMII transmit data 0 |

| C37 | X_ETH1_RGMII_TXD1/PG14 | 3.3 V | O | PG14 | AA1 | ETH1 RGMII transmit data 1 |

| C38 | X_ETH1_RGMII_TXD2/PC2 | 3.3 V | O | PC2 | Y2 | ETH1 RGMII transmit data 2 |

| C39 | X_ETH1_RGMII_TXD3/PE2 | 3.3 V | O | PE2 | Y1 | ETH1 RGMII transmit data 3 |

| C40 | X_ETH1_RGMII_TX_CTL/PB11 | 3.3 V | I/O | PB11 | AB1 | ETH1 RGMII transmit control (TX_EN + TX_ER) |

| C41 | X_ETH1_RGMII_GTX_CLK/PG4 | 3.3 V | O | PG4 | AB2 | ETH RGMII transmit clock |

| C42 | GND | |||||

| C43 | X_ETH1_MDC/PC1 | 3.3 V | O | PC1 | AA6 | Ethernet management data clock |

| C44 | X_ETH1_MDIO/PA2 | 3.3 V | I/O | PA2 | AC3 | Ethernet management data I/O |

| C45 | X_ETH1_nINT/PG12 | 3.3 V | I | PG12 | K4 | Ethernet interrupt (low active) |

| C46 | X_ETH1_RGMII_CLK125/PG5 | 3.3 V | I | PG5 | Y6 | External clock RX provided by the Ethernet PHY |

| C47 | GND | |||||

| C48 | X_RTC_EVI | 3.3 V | I-PD | RTC_EVI | RTC external event input; 10 kΩ pull-down | |

| C49 | X_nRTC_INT | 3.3 V | OD | RTC_INTn | RTC interrupt output; open-drain; active low | |

| C50 | X_RTC_CLKOUT | 3.3 V | O | RTC_CLKO | RTC Clock output | |

| C51 | X_PWR_ON | 3.3 V | O | PWR_ON | R2 | Power-ON output |

| C52 | VBUS_SW | 5.0 V | PWR_O | PMIC-SWOUT | 5 V / 500 mA USB-host power out | |

| C53 | VBUS_OTG | 5.0 V | PWR_O | PMIC-VBUSOTG | 5 V / 500 mA USB-OTG power out | |

| C54 | GND | |||||

| C55 | VDD_BUCK4 | 3.3 V | PWR_O | PMIC-BUCK4 | 3.3 V / 1 A PMIC-BUCK4 out | |

| C56 | VDD_BUCK4 | 3.3 V | PWR_O | PMIC-BUCK4 | 3.3 V / 1 A PMIC-BUCK4 out | |

| C57 | GND | |||||

| C58 | VCC5V_IN | 5.0 V | PWR_I | PMIC-VIN | 5 V main supply voltage | |

| C59 | VCC5V_IN | 5.0 V | PWR_I | PMIC-VIN | 5 V main supply voltage | |

| C60 | VCC5V_IN | 5.0 V | PWR_I | PMIC-VIN | 5 V main supply voltage |

| Pin No. | Signal Name | Level | Type | Pin Name | BGA361-Pad | Description |

|---|---|---|---|---|---|---|

| D1 | GND | |||||

| D2 | X_USB_OTG_VBUS | 5.0 V | PWR_I | OTG_VBUS | AC19 | USB OTG VBUS input |

| D3 | X_USB_OTG_D2P | 3.3 V | USB_I/O | USB_DP2 | AC16 | USB OTG data plus |

| D4 | X_USB_OTG_D2M | 3.3 V | USB_I/O | USB_DM2 | AB16 | USB OTG data minus |

| D5 | GND | |||||

| D6 | X_USB_HOST_D1M | 3.3 V | USB_I/O | USB_DM1 | AB17 | USB host data minus |

| D7 | X_USB_HOST_D1P | 3.3 V | USB_I/O | USB_DP1 | AC17 | USB OTG data plus |

| D8 | X_USB_OTG_ID/PA10 | 3.3 V | I | PA10 | Y17 | USB OTG ID Pin |

| D9 | GND | |||||

| D10 | X_USART3_RX/PB12 | 3.3 V | I | PB12 | AC5 | USART3 RXD in |

| D11 | X_USART3_TX/PB10 | 3.3 V | O | PB10 | Y3 | USART3 TXD out |

| D12 | X_USART3_RTS/PG8 | 3.3 V | O | PG8 | AB9 | USART3 RTS out |

| D13 | X_USART3_CTS/PB13 | 3.3 V | I | PB13 | AA10 | USART3 CTS in / CAN FD2 RXD |

| D14 | GND | |||||

| D15 | X_SAI2_SD_A/PI6 | 3.3 V | I/O | PI6 | F4 | SAI2 SDA |

| D16 | X_SAI2_SD_B/PF11 | 3.3 V | I/O | PF11 | Y10 | SAI2 SDB |

| D17 | X_SAI2_SCK_B/PH2 | 3.3 V | I/O | PH2 | AB4 | SAI2 SCKB |

| D18 | X_SAI2_MCLK_B/PH3 | 3.3 V | I/O-O | PH3 | AA3 | SAI2 MCLKB |

| D19 | X_SAI2_FS_B/PC0 | 3.3 V | I/O | PC0 | AB5 | SAI2 FSB |

| D20 | GND | |||||

| D21 | X_I2C4_SCL/PZ4 | 3.3 V | O | PZ4 | G2 | I2C4 used for internal I2C devices |

| D22 | X_I2C4_SDA/PZ5 | 3.3 V | I/O | PZ5 | H2 | |

| D23 | X_I2C1_SCL/PF14 | 3.3 V | I/O | PF14 | AC4 | I2C1 SCL out |

| D24 | X_I2C1_SDA/PF15 | 3.3 V | I/O | PF15 | Y4 | I2C1 SDA I/O |

| D25 | X_I2C2_SDA/PH5 | 3.3 V | I/O | PH5 | A2 | GPIO PH5 |

| D26 | GND | |||||

| D27 | X_DBTRGI/PA14 | 3.3 V | I | PA14 | T2 | External trigger input to the cross trigger interface (CTI) |

| D28 | X_DBTRGO/PA13 | 3.3 V | O | PA13 | N2 | External trigger output from the cross trigger interface (CTI) |

| D29 | GND | |||||

| D30 | X_ETH_A+ | 3.3 V | ETH_I/O | ETH-PHY | Ethernet data A+ | |

| D31 | X_ETH_A- | 3.3 V | ETH_I/O | ETH-PHY | Ethernet data A- | |

| D32 | GND | |||||

| D33 | X_ETH_B+ | 3.3 V | ETH_I/O | ETH-PHY | Ethernet data B+ | |

| D34 | X_ETH_B- | 3.3 V | ETH_I/O | ETH-PHY | Ethernet data B- | |

| D35 | GND | |||||

| D36 | X_ETH_C+ | 3.3 V | ETH_I/O | ETH-PHY | Ethernet data C+ | |

| D37 | X_ETH_C- | 3.3 V | ETH_I/O | ETH-PHY | Ethernet data C- | |

| D38 | GND | |||||

| D39 | X_ETH_D+ | 3.3 V | ETH_I/O | ETH-PHY | Ethernet data D+ | |

| D40 | X_ETH_D- | 3.3 V | ETH_I/O | ETH-PHY | Ethernet data D- | |

| D41 | GND | |||||

| D42 | X_ETH_LED0_LINK | 3.3 V | OD | ETH-PHY_LED0 | Ethernet link LED output | |

| D43 | X_ETH_LED1_GBIT | 3.3 V | OD | ETH-PHY_LED1 | Ethernet Gb indication LED output | |

| D44 | X_ETH_LED2_ACT | 3.3 V | OD | ETH-PHY_LED2 | Ethernet traffic LED output | |

| D45 | X_ETH_GPIO0 | 3.3 V | I/O | ETH-PHY_GPIO0 | Ethernet PHY GPIO0 (Ethernet PHY (U3)) | |

| D46 | X_ETH_GPIO1 | 3.3 V | I/O | ETH-PHY_GPIO1 | Ethernet PHY GPIO1 (Ethernet PHY (U3)) | |

| D47 | X_PG1 | 3.3 V | I/O | PG1 | W1 | GPIO PG1 |

| D48 | X_PF3 | 3.3 V | I/O | PF3 | U1 | GPIO PF3 |

| D49 | X_MCO2/PG2 | 3.3 V | O | PG2 | V2 | Master clock out |

| D50 | GND | |||||

| D51 | X_nRESET | 3.3 V | I/O-OD | NRST | M3 | Reset in/out open drain with 10 kΩ pull-up |

| D52 | X_nPMIC_INT/PA0 | 3.3 V | I | PA0 | AB3 | Input for interrupt from PMIC or external |

| D53 | X_WAKEUP3/PC13 | 3.3 V | I/O | PC13 | K2 | GPIO PC13 (PMIC-Wakeup in) |

| D54 | X_nPONKEY | 3.3 V | I | PMIC-PONKEYn | PMIC power-on key (active low) | |

| D55 | VDD_LDO1 | PWR_O | PMIC-LDO1 | PMIC-LDO1 programmable output | ||

| D56 | VDD | 3.3 V | PWR_O | VDD | 3.3 V VDD out (only for reference) | |

| D57 | VBAT | 1.8 V - 3.6 V | PWR_I | RTC_VBKUP | 1.8 V to 3.6 V backup supply | |

| D58 | GND | |||||

| D59 | VCC5V_IN | 5.0 V | PWR_I | PMIC-VIN | 5 V main supply voltage | |

| D60 | VCC5V_IN | 5.0 V | PWR_I | PMIC-VIN | 5 V main supply voltage |

Jumpers

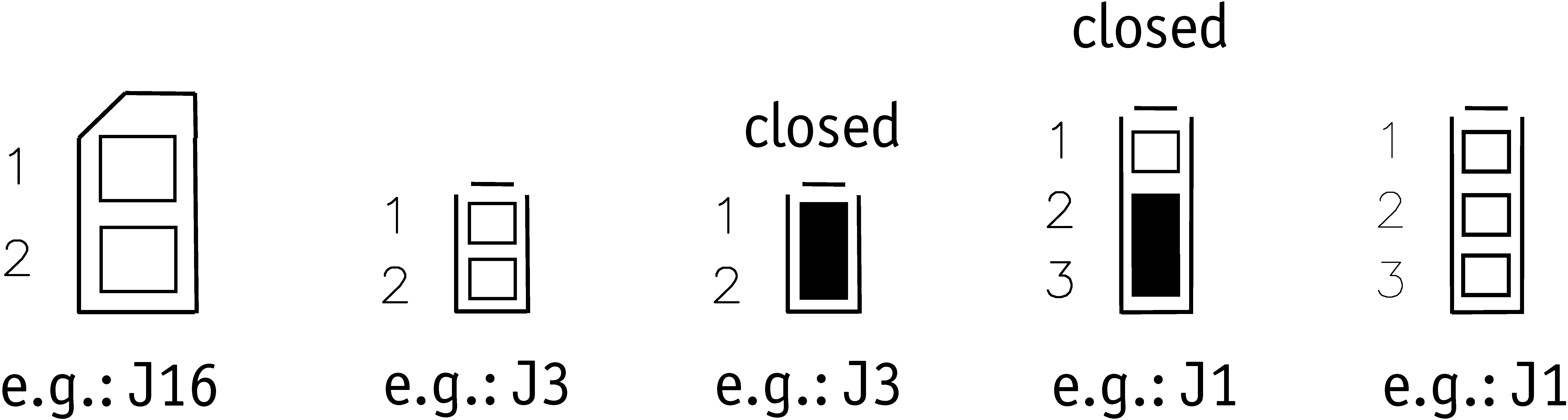

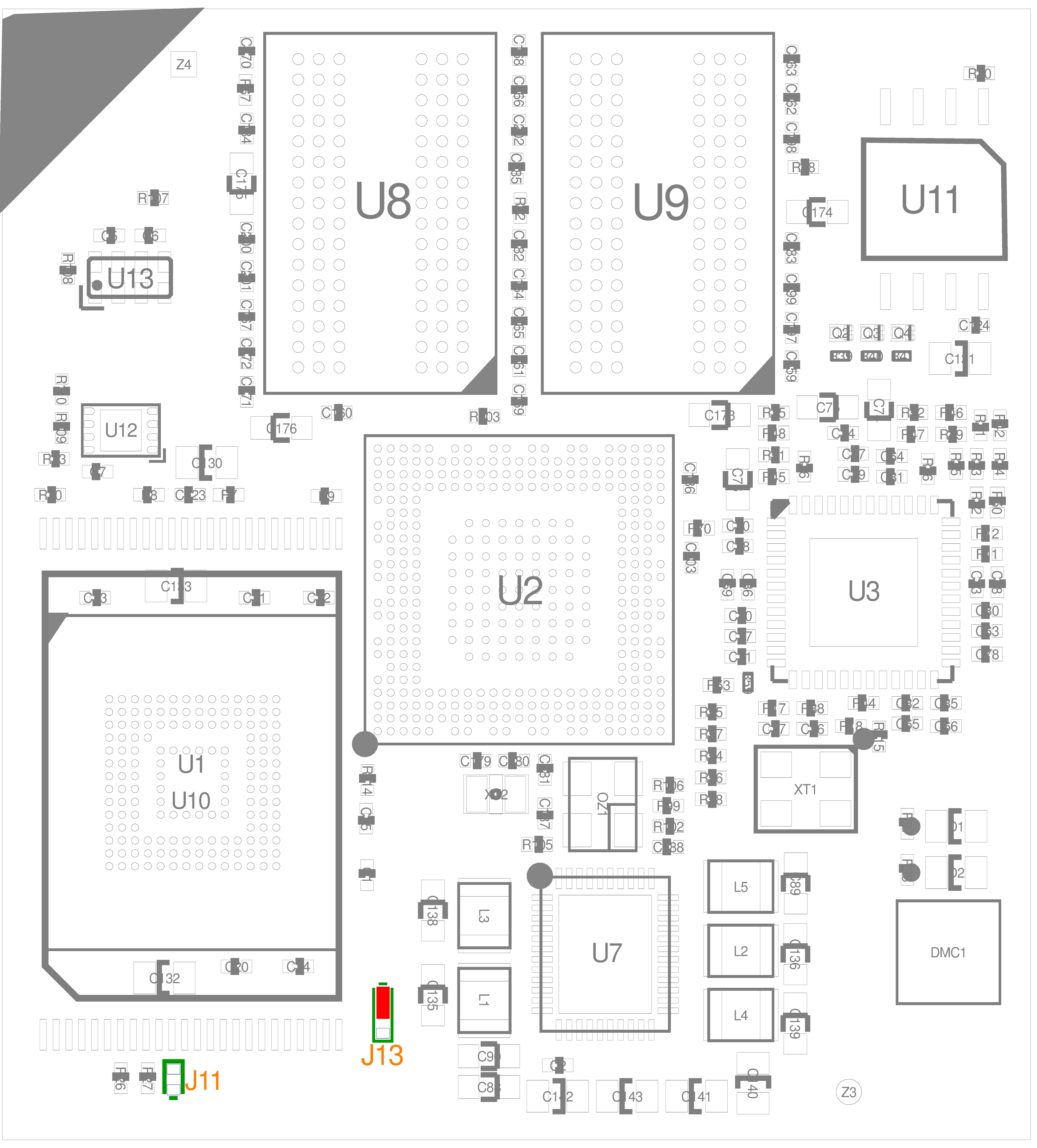

For configuration purposes, the phyCORE‑STM32MP15x has several solder jumpers, some of which have been installed prior to delivery. The figure below, Typical Jumper Pad Numbering Scheme, illustrates the numbering scheme for the various solder jumper pads.Jumper Locations (Top View)and Jumper Locations (Bottom View) indicate the location and the default configuration of the solder jumpers on the board.

Table Jumper Settings provides a functional summary of the solder jumpers which can be changed to adapt the phyCORE‑STM32MP15x to specific design needs. It shows their default positions, and possible alternative positions and functions. A detailed description of each solder jumper can be found in the applicable chapter listed in the table.

Tip

Jumpers not listed should not be changed as they are installed with regards to the configuration of the phyCORE‑STM32MP15x.

If manual jumper modification is required, please ensure that the board, as well as surrounding components and sockets, remain undamaged while desoldering. Overheating the board can cause the solder pads to loosen, rendering the module inoperable. If soldered jumpers need to be removed, the use of a desoldering pump, desoldering braid, an infrared desoldering station, desoldering tweezers, hot air rework station, or other desoldering method is strongly recommended. Follow the instructions carefully for whatever method of removal is used.

Warning

If any modifications to the module are performed, regardless of their nature, the manufacturer guarantee is voided.

Pay special attention to the “TYPE” column to ensure you are using the correct type of jumper (0 Ohms, 10k Ohms, etc…). The jumpers are 0402 packages with a 1/8 W or better power rating. The jumpers (J = solder jumper) have the following functions.

| Jumper | Position | Description | Type | Section |

|---|---|---|---|---|

| J1 | 1+2 | PDR_ON connected to VDD, VDD OK detector enabled | 0402 | |

| 2+3 | PDR_ON connected to GND, VDD OK detector disabled | |||

| J2 | 1+2 | PDR_ON_CORE connected to VDD, VDDCORE OK detector enabled | 0402 | |

| 2+3 | PDR_ON_CORE connected to GND, VDDCORE OK detector disabled | |||

| J3 | open | Interrupt output from PMIC not used, PA0 freely available at X1D52 | 0402 | |

| closed | Interrupt output from PMIC connected to X_nPMIC_INT/PA0 | |||

| J4 | open | Wake-up input from PMIC not used, PC13 freely available at X1D53 | 0402 | |

| closed | Wake-up input from PMIC connected to X_WAKEUP3/PC13 | |||

| J5 | 1+2 | Only external RTCs are supplied through VBAT input (D57), whileSTM32MP15x backup domain Vsw is supplied by the main system power VDD |

| |

| 2+3 | External RTC and STM32MP15x backup domain Vsw supplied via backup supply input pin VBAT (D57) | |||

| J9 | 1+2 | Voltage resulting from jumper J10 configuration (VDD or VDD_BUCK4) connected to PMIC's LDO regulators 2 and 5 input | 0402 | |

| 2+3 | VCC5V_IN selected as the supply voltage for the PMIC's LDO regulators 2 and 5 | |||

| J10 | 1+2 | VDD_BUCK4 used as Ethernet supply voltage (VDD_ETH_3V3) and jumper J9 input (pin 1) | 0402 | |

| 2+3 | VDD used as Ethernet supply voltage (VDD_ETH_3V3) and jumper J9 input (pin 1) | |||

| J13 | 1+2 | write protection of the NAND flash device U10 is only enabled during RESET | 0402 | |

| 2+3 | write protection of the NAND flash device U10 permanently enabled | |||

| J14 | open | VREF not connected to VDDA (for STM32MP15x internal reference or external VREF from X1C15) | 0402 | |

| closed | VREF connected to VDDA (supplied by VDD (J16) or VDDA (J15) of the PMIC's LDO5) | |||

| J15 | open | STM32MP15x's VDDA is not connected to PMIC's VDDA (J16 must be closed!) | 0402 | |

| closed | VDDA connected to VDDA of the PMIC's LDO5 (J16 must be open!) | |||

| J16 | open | VDDA not connected to VDD (J15 must be closed!) | 0805 | |

| closed | VDDA connected to VDD (J15 must be open!) | |||

| J17 | 1+2 | Boot configuration input BOOT0 connected to VDD | 10 k 0402 | |

| 2+3 | Boot configuration input BOOT0 connected to GND | |||

| J18 | 1+2 | Boot configuration input BOOT1 connected to VDD | 10 k 0402 | |

| 2+3 | Boot configuration input BOOT1 connected to GND | |||

| J19 | 1+2 | Boot configuration input BOOT2 connected to VDD | 10 k 0402 | |

| 2+3 | Boot configuration input BOOT2 connected to GND | |||

| J20 | 1+2 | 1V8 regulator disabled if VDD < 2.25 V, VDDA1V8_REG pin must be connected to VDD or a dedicated 1.65 V - 1.98 V supply (1.8 V typ.) | 0402 | |

| 2+3 | 1V8 regulator enabled, VDD must be > 2.25 V |

Power

The phyCORE‑STM32MP15x operates off of a single power supply voltage. The following sections discuss the primary power pins on the phyCORE‑Connector X1 in detail.

Primary System Power (VCC5V_IN)

The phyCORE‑STM32MP15x is powered by a primary voltage supply with a nominal value of +5 V. On-board switching regulators generate the voltage supplies required by the STM32MP15x MCU and on-board components from the primary 5 V supplied to the SOM. For proper operation, the phyCORE‑STM32MP15x must be supplied with a voltage source of 5 V ±5 % with 3 A load at the VCC5V_IN pins on the phyCORE-Connector X1.

VCC5V_IN: X1 → C58, C59, C60, D59, D60

Connect all +5 V VCC input pins to your power supply and all available GND pins. Please refer to section Pin Description for information on additional GND Pins located at the phyCORE‑Connector X1.

Warning

As a general design rule, all GND pins must be connected to a solid ground plane.

Power Management IC (PMIC) (U7)

The phyCORE‑STM32MP15x provides an onboard Power Management IC (PMIC) at position U7 to generate different voltages required by the microcontroller and the onboard components. The PMIC supports many functions such as different power management functionalities like dynamic voltage control, different low power modes, and regulator supervision. It is connected to the STM32MP15x via the onboard I2C bus (I2C4). The I2C address of the PMIC is 0x33.

External voltages:

- VCC5V_IN 5 V main supply voltage

- VBAT 3 V Backup Supply for RTC and STM32MP15x backup domain Vsw (optionally)

- VDD I/O supply voltage output

- VDD_BUCK4 PMIC BUCK4 converter output

- VDD_LDO1 PMIC LDO1 output

Supply Voltage for External Logic

The voltage level of the phyCORE’s logic circuitry is VDD (3.3 V), which is derived from the SOM main input voltage VDD5V_IN. In order to follow the power-up and power-down sequencing mandatory for the STM32MP15x, external devices have to be supplied by the I/O supply voltage VDD or VDD_BUCK4 (3.3 V) which is brought out at pin X1D56 (VDD) and pins X1C55 + X1C56 (VDD_BUCK4) of the phyCORE-Connector. The use of VDD ensures that external components are only supplied when the supply voltages of the STM32MP15x are stable.

VDD_BUCK4 (3.3 V / max. 1 A) output at pins X1C55 and X1C56 can be used also to supply external circuits connected to the phyCORE‑STM32MP15x.

Warning

- The current draw for VDD must not exceed 10 mA. Consequently, this voltage should only be used as a reference, for level shifters or switch supply voltage from other sources, not for supplying purposes. If devices with higher power consumption are connected to the phyCORE‑STM32MP15x, their supply voltage should be switched on and off by the use of the VDD or VDD_BUCK4 signal. This way, the power-up, and power-down sequencing will be considered even if the devices are not supplied directly by VDD. Additionally, a voltage supervisor should be added to the carrier board. This supervisor should be powered by VDD and hold X_nRESET (X1D51) low, as long as the externally generated voltages are not in proper shape.

- Take care not to overload the VDD_BUCK4 output or exceed the thermal limits of the PMIC on the phyCORE‑STM32MP15x!

Backup Power (VBAT)

To back up the RTC at U13 and, optionally, the STM32MP15x's backup domain Vsw, an external voltage source of 1.8 V to 3.6 V can be connected to VBAT pin D57.

If jumper J5 is closed at 1+2 (default setting), only the RTC at U13, which has an extremely low backup current consumption of typ. 40 nA @3 V (max. 500 nA), is supplied by the backup source.

Additionally, it is possible to supply the STM32MP15x's internal RTC, some registers, and SRAM via backup domain Vswby the VBAT voltage if jumper J5 is set to 2+3.

Tip

In order to get the minimum power consumption to back up the RTC while the main supply voltage is not available, jumper J5 must be closed at 1+2 (default configuration). Otherwise, the STM32MP15x's backup domain Vsw will be supplied by the backup voltage source, too.

Power Supply Supervisor

The STM32MP15x has an integrated power-on reset (POR)/ power-down reset (PDR) circuitry coupled with a Brownout reset (BOR) circuitry. Two jumpers (J1 and J2) allow the configuration of the power supply supervisor.

- J1 connects PDR_ON either to VDD or to GND, enabling or disabling the power-down reset (PDR). If PDR is enabled the PDR supervisor monitors the VDD power supply. A reset is generated when VDD drops below a fixed threshold.

- J2 connects PDR_ON_CORE either to VDD or to GND, enabling or disabling the power-down reset VDDCORE (PDR_VDDCORE). If PDR_VDDCORE is enabled the PDR_VDDCORE supervisor monitors the VDDCORE power supply. A VDDCORE domain reset is generated when VDDCORE drops below a fixed threshold.

The following configurations are possible:

| J1 | PDR supervisor enable/disable |

|---|---|

| 1+2 | PDR_ON connected to VDD, VDD OK detector enabled |

| 2+3 | PDR_ON connected to GND, VDD OK detector disabled |

| J2 | PDR_ON_CORE supervisor enable/disable |

|---|---|

| 1+2 | PDR_ON_CORE connected to VDD, VDDCORE OK detector enabled |

| 2+3 | PDR_ON_CORE connected to GND, VDDCORE OK detector disabled |

Warning

When the PDR_ON pin is connected to GND (internal reset OFF), the VBAT functionality is no more available and the VBAT pin must be connected to VDD by ensuring that jumper J5 is closed in the default position 1+2.

CPU Core Frequency Scaling

The STM32MP15x on the phyCORE‑STM32MP15x is able to scale the clock frequency and voltage. This is used to save power when the full performance of the CPU is not needed. Scaling the frequency and voltage is referred to as 'Dynamic Voltage and Frequency Scaling' (DVFS).

The phyCORE‑STM32MP15x BSP supports the DVFS feature. The Linux kernel provides a DVFS framework that allows each CPU core to have a min/max frequency as well as the applicable voltage and a governor that governs these values depending on the system load. Depending on the STM32MP15x variant used, several different frequencies are supported. Further details on how to configure this governor can be found in the phyCORE‑STM32MP15x BSP Manual.

Reset

The X_nRESET signal (Pin X1D61) on the phyCORE-Connector is designated as the reset input/output. Holding this pin low triggers a hard reset of the module. X_nRESET can be used to prevent the boot-up of the STM32MP15x. This can be used as a startup as described in the sectionPower Management IC.

System Boot Configuration

Most features of the STM32MP15x microcontroller are configured and/or programmed during the initialization routine. Other features, which impact program execution, must be configured prior to initialization via pin termination.

The system start-up configuration includes:

- Boot mode selection

- Boot device selection

- Boot device configuration

The internal ROM code is the first code executed during the initialization process of the STM32MP15x after POR. The ROM code detects the boot mode and configuration by using the boot mode pins (BOOT[2:0]).

Boot Mode Selection

The boot mode of the STM32MP15x microcontroller is determined by the configuration of three boot mode inputs BOOT[2:0] of the STM32MP15x during the reset cycle of the operational system.

Configuration circuitry (10 kΩ pull-up and pull-down resistors on jumpers J17 to J19 connected to BOOT[2:0]) is located on the phyCORE‑STM32MP15x so no further settings are necessary. The boot configuration of pins BOOT[2:0] on the standard phyCORE‑STM32MP15x module is 0b010. Consequently, the system will try to boot from eMMC first.

Additionally, the boot mode inputs are brought out at the phyCORE‑Connector pins X_BOOT[2:0] (X1C21, X1C20, X1C19). Hence, the specific boot configuration settings, which are set by the on-board configuration resistors, can be changed by modifying jumpers J17 to J19 on the module or by connecting a configuration resistor (e.g. <1 kΩ pull-up) to the BOOT signal pins at the phyCORE-Connector.

The table phyCORE-STM32MP15x Boot Modes shows the possible settings and the resulting boot configuration of the STM32MP15x.

| Boot Mode | BOOT2 (J19 / X1C21) | BOOT1 (J18 / X1C20) | BOOT0 (J17 / X1C19) |

|---|---|---|---|

| UART/USB-HS device | 0 (J19: 2+3) | 0 (J18: 2+3) | 0 (J17: 2+3) |

| QSPI NOR Flash on QSPI-BK1 | 0 (J19: 2+3) | 0 (J18: 2+3) | 1 (J17: 1+2) |

| eMMC on SDMMC2 | 0 (J19: 2+3) | 1 (J18: 1+2) | 0 (J17: 2+3) |

| SLC NAND Flash on FMC | 0 (J19: 2+3) | 1 (J18: 1+2) | 1 (J17: 1+2) |

| Reserved | 1 (J19: 1+2) | 0 (J18: 2+3) | 0 (J17: 2+3) |

| SD card on SDMMC1 | 1 (J19: 1+2) | 0 (J18: 2+3) | 1 (J17: 1+2) |

| UART/USB-OTG-HS device | 1 (J19: 1+2) | 1 (J18: 1+2) | 0 (J17: 2+3) |

| Reserved | 1 (J19: 1+2) | 1 (J18: 1+2) | 1 (J17: 1+2) |

Warning

Make sure that the boot mode inputs X_BOOT[2:0] (X1C21, X1C20, X1C19) are not driven by any device on the carrier board during reset. This is to avoid accidental changes to the boot configuration.

System Memory

The phyCORE‑STM32MP15x provides five types of on-board memory:

- 1x bank of 32-bit DDR3L RAM: 256 MB (up to 1 GB)

- eMMC: 4 GB (up to 128 GB)

or

SLC NAND flash: 128 MB (up to 1 GB) - Quad SPI NOR flash: 4 MB (up to 16 MB)

- I²C-EEPROM: 4 kB (up to 32 kB)

Details for each memory type used on the phyCORE‑STM32MP15x are below.

DDR3L-SDRAM (U8, U9)

The RAM memory of the phyCORE‑STM32MP15x is comprised of two 16-bit wide DDR3L-SDRAM chips (U8, U9). The memory devices are connected to the dedicated DDRPHYC SDRAM interface of the STM32MP15x microcontroller.

The DDR3-SDRAM memory is accessed starting at address 0xC000 0000.

The DDR memory subsystem of the STM32MP15x is composed of the DDRCTRL and the DDRPHYC and provides a complete memory interface. Typically, the DDR3-RAM initialization is performed by a boot loader or operating system following a power-on reset and must not be changed at a later point by any application code. When writing custom code independent of an operating system or boot loader, the DDRPHYC SDRAM interface and the DDRCTRL must be initialized by accessing the appropriate configuration registers on the STM32MP15x controller. Refer to the STM32MP15x Reference Manual to access and configure these registers.

Flash Memory (U1, U10)

Use of Flash as non-volatile memory on the phyCORE-SM32MP1 provides an easily reprogrammable means of code storage. The phyCORE‑STM32MP15x can be equipped with either an eMMC (U1) memory device or a NAND flash (U10) as non-volatile memory.

eMMC Memory (U1)

The main flash memory of the STM32MP15x is a managed NAND (eMMC) flash device populated at U1. The eMMC device is programmable with 3.3 V. No dedicated programming voltage is required. The eMMC Flash memory is connected to the second Secure digital input/output MultiMediaCard interface (SDMMC2) of the STM32MP15x. For more information about the SDMMC interfaces, please refer to the STM32MP15x Reference Manual.

If the phyCORE‑STM32MP15x is equipped with a NAND flash at U10 instead of the eMMC device (see next section), SDMMC2 is available at the phyCORE-Connector X1.

SOM Connector Pin | SOM Signal Name | Signal Level | Signal Type | Description |

|---|---|---|---|---|

| A11 | X_SDMMC2_DATA0/PB14 | 3.3 V | I/O | SD/SDIO/eMMC card data line 0 |

| A12 | X_SDMMC2_DATA1/PB15 | 3.3 V | I/O | SD/SDIO/eMMC card data line 1 |

| A13 | X_SDMMC2_DATA2/PB3 | 3.3 V | I/O | SD/SDIO/eMMC card data line 2 |

| A14 | X_SDMMC2_DATA3/PB4 | 3.3 V | I/O | SD/SDIO/eMMC card data line 3 |

| A15 | X_SDMMC2_DATA4/PA8 | 3.3 V | I/O | SD/SDIO/eMMC card data line 4 |

| A16 | X_SDMMC2_DATA5/PA9 | 3.3 V | I/O | SD/SDIO/eMMC card data line 5 |

| A17 | X_SDMMC2_DATA6/PC6 | 3.3 V | I/O | SD/SDIO/eMMC card data line 6 |

| A18 | X_SDMMC2_DATA7/PD3 | 3.3 V | I/O | SD/SDIO/eMMC card data line 7 |

| A20 | X_SDMMC2_CMD/PG6 | 3.3 V | I/O | SD/SDIO/eMMC card bidirectional command/response signal |

| A21 | X_SDMMC2_CLK/PE3 | 3.3 V | O | SD/SDIO/eMMC card clock |

Note

Other interface signals (SDMMC_CKIN, SDMMC_CDIR, SDMMC_D0DIR, SDMMC_D123DIR) belonging to the second Secure digital input/output MultiMediaCard interface (SDMMC2) are also available at different pins of the phyCORE-Connector. However, the standard pin muxing of the phyCORE‑STM32MP15x assigns other functions to these pins. Hence the pin muxing must be changed if signals SDMMC_CKIN, SDMMC_CDIR, SDMMC_D0DIR, and SDMMC_D123DIR are needed.

Please refer to the STM32MP15x Data Sheet for details on the pin-muxing options.

NAND Flash Memory (U10)

Alternatively to the eMMC memory at U1, a NAND flash can be populated at U10. The NAND Flash memory is connected to the STM32MP15x's Flexible Memory Controller (FMC) interface with a bus width of 8-bits. NCE1 (FMC_NCE/PG9) of the FMC interface selects the NAND Flash at U10. The FMC interface is also available at the phyCORE-Connector and can be used if no NAND flash is mounted on U10. These signals are available without changing the pin multiplexing of the phyCORE‑STM32MP15x.

SOM Connector Pin | SOM Signal Name | Signal Level | Signal Type | Description |

|---|---|---|---|---|

| B20 | X_FMC_DATA0/PD14 | 3.3 V | I/O | Address / Data 0 |

| B21 | X_FMC_DATA1/PD15 | 3.3 V | I/O | Address / Data 1 |

| B22 | X_FMC_DATA2/PD0 | 3.3 V | I/O | Address / Data 2 |

| B23 | X_FMC_DATA3/PD1 | 3.3 V | I/O | Address / Data 3 |

| B24 | X_FMC_DATA4/PE7 | 3.3 V | I/O | Address / Data 4 |

| B25 | X_FMC_DATA5/PE8 | 3.3 V | I/O | Address / Data 5 |

| B26 | X_FMC_DATA6/PE9 | 3.3 V | I/O | Address / Data 6 |

| B27 | X_FMC_DATA7/PE10 | 3.3 V | I/O | Address / Data 7 |

| B29 | X_FMC_nWAIT/PD6 | 3.3 V | I | Input for external ready/busy (wait) signal (active low) |

| B30 | X_FMC_nOE/PD4 | 3.3 V | O | Output enable/ Read enable (active low) |

| B31 | X_FMC_nCE/PG9 | 3.3 V | O | Chip select 1 |

| B32 | X_FMC_CLE/PD11 | 3.3 V | O | Command latch enable |

| B33 | X_FMC_ALE/PD12 | 3.3 V | O | Address latch enable |

| B34 | X_FMC_nNWE/PD5 | 3.3 V | O | Write enable (active low) |

The flash devices are programmable with 3.3 V. No dedicated programming voltage is required.

As of the printing of this manual, these NAND flash devices generally have a life expectancy of at least 100,000 erase/program cycles and a data retention rate of 10 years.

Any parts that are footprint (TSOP48) and functionally compatible may be used with the phyCORE‑STM32MP15x.

NAND Flash Write Protection Control (J13)

Jumper J13 controls the write protection feature of the NAND flash at U10. Setting this jumper to position 1+2 protects the flash against write access during a power-on reset cycle. Setting this jumper to 2+3 protects the NAND flash permanently against write cycles.

The following configurations are possible:

| J13 | NAND Flash Write Protection State |

|---|---|

| 1+2 | Write protection enabled during power-on reset |

| 2+3 | Write protection enabled permanently |

Quad SPI NOR Flash (U11)

The QSPI NOR flash memory of the phyCORE‑STM32MP15x at U11 is available on most standard configurations of the SOM and can be used to store configuration data or any other general-purpose data. Besides this, it can also be used as a boot device and recovery boot device and is, therefore, suitable for applications that require a small code footprint or small RTOSes.

Tips

Using a QSPI Flash can eliminate the need to install eMMC or NAND flash memory on the SOM. This could reduce BOM costs, free up the ports used as SDMMC2 or FMC interface for other devices to be connected to the phyCORE‑STM32MP15x, and remove the need for doing the bad block management that is required when using NAND flash.

The device is connected to bank 1 of the STM32MP15x's Quad-SPI interface (QUAD SPI) and can be accessed through QUADSPI_BK1_NCS. The control registers for QSPI are mapped between addresses 0x58003000 and 0x58003FFF. Please see the STM32MP15x Reference Manual for detailed information on the registers.

In order to allow connecting an external Quad SPI flash if the phyCORE‑STM32MP15x comes without an onboard Quad SPI flash, the QSPI signals are available at phyCORE-Connector X1.

SOM Connector Pin | SOM Signal Name | Signal Level | Signal Type | Description |

|---|---|---|---|---|

| C4 | X_QSPI_BK1_DATA0/PF8 | 3.3 V | I/O | QSPI Bidirectional IO0 |

| C5 | X_QSPI_BK1_DATA1/PF9 | 3.3 V | I/O | QSPI Bidirectional IO1 |

| C6 | X_QSPI_BK1_DATA2/PF7 | 3.3 V | I/O | QSPI Bidirectional IO2 |

| C7 | X_QSPI_BK1_DATA3/PF6 | 3.3 V | I/O | QSPI Bidirectional IO3 |

| C8 | X_QSPI_QSPI_BK1_nCS/PB6 | 3.3 V | O | QSPI chip select for bank 1 (low active) |

| C9 | X_QSPI_QSPI_CLK/PF10 | 3.3 V | O | QSPI clock signal |

Note

The interface signals for the second bank of the Quad-SPI interface (QUAD SPI) are also available at different pins of the phyCORE-Connector. However, the standard pin muxing of the phyCORE‑STM32MP15x assigns other functions to these pins. Hence the pin muxing must be changed if a second QSPI flash should be connected...

Please refer to the STM32MP15x Data Sheet for details on the pin-muxing options.

As of the printing of this manual, these SPI Flash devices generally have a life expectancy of at least 100,000+ erase/program cycles and a data retention rate of 20 years. This makes the OSPI NOR flash a reliable and secure solution to store the first and second-level bootloaders.

I2C EEPROM (U12)

The standard configuration of the phyCORE‑STM32MP15x is populated with a non-volatile 4 kB I2C EEPROM at U12. This memory can be used to store configuration data or other general-purpose data. This device is accessed through I2C port 4 on the STM32MP15x. The control registers for I2C port 4 are mapped between addresses 0x5C002000 and 0x5C0023FF. Please see the STM32MP15x Reference Manual for detailed information on the registers.

The I²C EEPROM populating the phyCORE‑STM32MP15x has the ability to configure the address for the memory area and the additional ID page using chip-enabled signals E0 to E2. The four upper address bits of the device are fixed at ‘1010’ (see M24C32 datasheet). Chip-enable signals E0 to E2 are fixed and connected to GND. Thus the resulting addresses are 0x50 for the memory array and 0x58 for the additional ID page.

EEPROM Write Protection Control (R23)

Mounting a 10 kΩ resistor at R23 will cause the EEPROM to enter write-protect mode, thereby disabling write access to the device. In the default configuration resistor, R23 is not mounted which means write access to the device is allowed.

The following configurations are possible:

| R23 | EEPROM Write Protection State |

|---|---|

| open | Write access allowed |

| 10 kΩ resistor mounted | EEPROM is write-protected |

Serial Interfaces

The phyCORE‑STM32MP15x provides numerous dedicated serial interfaces, some of which are equipped with a transceiver/PHY to allow direct connection to external devices, others can be muxed to other pins. The STM32MP15x has some more interfaces that can be used by individual pin muxing. This chapter only describes the predefined interfaces.

- 1x High-speed USB OTG interface (extended directly from the second port of the STM32MP15x's USB high-speed PHY)

- 1x High-speed USB host interface (extended directly from the first port of the STM32MP15x's USB high-speed PHY)

- 1x Gbit Ethernet interface

- 2x I2C interfaces

- 1x Serial Peripheral Interfaces (SPI)

- 3x UART interfaces

- 2x CAN FD interfaces

- 3x SDIO interfaces

- 1x SAI interface

The following sections of this chapter detail each of these serial interfaces and any applicable configuration jumpers.

USB OTG Interface

The phyCORE‑STM32MP15x provides a high-speed USB OTG interface that uses the STM32MP15x's embedded high-speed USB OTG IP-Core connected to the second port of the embedded USB high-speed PHY. The USB OTG IP-Core supports both device and host functions and is fully compliant with the On-The-Go Supplement to the USB 2.0 specification. It can also be configured as a host-only or device-only controller. An external USB Standard-A (for USB host), USB Standard-B (for USB device), or USB mini-AB (for USB OTG) connector is all that is needed to interface the phyCORE‑STM32MP15x USB OTG functionality. The applicable interface signals can be found on the phyCORE-Connector X1 as shown in the following table.

SOM Connector Pin | SOM Signal Name | Signal Level | Signal Type | Description |

|---|---|---|---|---|

| D2 | X_USB_OTG_VBUS | 5.0 V | PWR_I | USB OTG VBUS input |

| D3 | X_USB_OTG_D2P | 3.3 V | USB_I/O | USB OTG data plus |

| D4 | X_USB_OTG_D2M | 3.3 V | USB_I/O | USB OTG data minus |

| D8 | X_USB_OTG_ID/PA10 | 3.3 V | I | USB OTG ID Pin |

| C53 | VBUS_OTG | 5.0 V | PWR_O | VBUS supply voltage from PMIC |

Warning

X_USB_OTG_VBUS must be supplied with 5 V for proper USB functionality.

USB host Interface

The phyCORE‑STM32MP15x provides a high-speed USB OTG interface that uses the STM32MP15x's embedded high-speed USB OTG IP-Core connected to the second port of the embedded USB high-speed PHY. The USB OTG IP-Core supports both device and host functions and is fully compliant with the On-The-Go Supplement to the USB 2.0 specification. It can also be configured as a host-only or device-only controller. An external USB Standard-A (for USB host), USB Standard-B (for USB device), or USB mini-AB (for USB OTG) connector is all that is needed to interface the phyCORE‑STM32MP15x USB OTG functionality. The applicable interface signals can be found on the phyCORE-Connector X1 as shown in the following table.

SOM Connector Pin | SOM Signal Name | Signal Level | Signal Type | Description |

|---|---|---|---|---|

| D6 | X_USB_HOST_D1M | 3.3 V | USB_I/O | USB host data minus |

| D7 | X_USB_HOST_D1P | 3.3 V | USB_I/O | USB OTG data plus |

| C52 | VBUS_SW | 5.0 V | PWR_O | VBUS supply voltage from PMIC |

Ethernet Interface

Connection of the phyCORE‑STM32MP15x to the World Wide Web or a local area network (LAN) is possible using the onboard GbE PHY at U3. It is connected to the RGMII interface (ETH1) of the STM32MP15x. The PHY operates with a data transmission speed of 10 Mbit/s, 100 Mbit/s, or 1000 Mbit/s. Alternatively, the RGMII (ETH1) interface which is available on the phyCORE-Connector can be used to connect an external PHY. In this case, the onboard GbE PHY (U3) must not be populated (section RGMII Interface).

Ethernet PHY (U3)

With an Ethernet PHY mounted at U3, the phyCORE‑STM32MP15x has been designed for use in 10Base-T, 100Base-T, and 1000Base‑T networks. The 10/100/1000Base‑T interface with its LED signals extends to phyCORE‑Connector X1.

SOM Connector Pin | SOM Signal Name | Signal Level | Signal Type | Description |

|---|---|---|---|---|

| D30 | X_ETH_A+ | 3.3 V | ETH_I/O | Ethernet data A+ |

| D31 | X_ETH_A- | 3.3 V | ETH_I/O | Ethernet data A- |

| D33 | X_ETH_B+ | 3.3 V | ETH_I/O | Ethernet data B+ |

| D34 | X_ETH_B- | 3.3 V | ETH_I/O | Ethernet data B- |

| D36 | X_ETH_C+ | 3.3 V | ETH_I/O | Ethernet data C+ |

| D37 | X_ETH_C- | 3.3 V | ETH_I/O | Ethernet data C- |

| D39 | X_ETH_D+ | 3.3 V | ETH_I/O | Ethernet data D+ |

| D40 | X_ETH_D- | 3.3 V | ETH_I/O | Ethernet data D- |

| D42 | X_ETH_LED0_LINK | 3.3 V | OD | Ethernet link LED output |

| D43 | X_ETH_LED1_GBIT | 3.3 V | OD | Ethernet Gb indication LED output |

| D44 | X_ETH_LED2_ACT | 3.3 V | OD | Ethernet traffic LED output |

The onboard GbE PHY supports HP Auto-MDIX technology, eliminating the need for a direct connect LAN or cross-over patch cable. It detects the TX and RX pins of the connected device and automatically configures the PHY TX and RX pins accordingly. The Ethernet PHY also features an auto-negotiation to automatically determine the best speed and duplex mode.

The Ethernet PHY is connected to the RGMII interface (ETH1) of the STM32MP15x. Please refer to the STMicroelectronics STM32MP15x Reference Manual for more information about this interface.

In order to connect the module to an existing 10/100/1000Base-T network, some external circuitry is required. The required termination resistors on the analog signals (X_ETH_A±, X_ETH_B±, X_ETH_C±, X_ETH_D±) are integrated into the chip, so there is no need to connect external termination resistors to these signals. Connection to external Ethernet magnetics should be done using very short signal traces. The A+/A-, B+/B-, C+/C-, and D+/D- signals should be routed as 100 Ohm differential pairs. The same applies to the signal lines after the transformer circuit. The carrier board layout should avoid any other signal lines crossing the Ethernet signals.

Warning

Please refer to the Ethernet PHY datasheet when designing the Ethernet transformer circuitry or request the schematic of the applicable carrier board (phyBOARD-Sargas STM32MP15x).

Ethernet PHY GPIOs

The Ethernet PHY mounted on the phyCORE‑STM32MP15x provides two additional GPIOs. These are available at pins D45 (X_ETH_GPIO0) and D46 (X_ETH_GPIO1) of the phyCORE‑Connector X1. They can be configured by the appropriate registers of the Ethernet PHY.

MAC Address

In a computer network such as a local area network (LAN), the MAC (Media Access Control) address is a unique computer hardware number. For a connection to the internet, a table is used to convert the assigned IP number to the hardware’s MAC address. In order to guarantee that the MAC address is unique, all addresses are managed in a central location. PHYTEC has acquired a pool of MAC addresses. The MAC address of the phyCORE‑STM32MP15x can be found on a sticker (with 2D matrix code) attached to the module. This number is a 12-digit HEX value.

The MAC address of the module is also programmed in the appropriate OTP (STM32MP15x's on-chip one-time programmable memory). Assigned OTP registers in the STM32MP15x:

OTP_57[31:0] = MAC_ADDR[31:0]

OTP_58[15:0] = MAC_ADDR[47:32]

RGMII Interface

In order to use an external Ethernet PHY instead of the on-board GbE PHY at U3, the RGMII interface (ETH1) of the STM32MP15x is brought out at phyCORE‑Connector X1.

Warning

The GbE PHY (U3) must not be populated on the module if the RGMII interface is used.

Anyway, it is not recommended to remove the Ethernet PHY and other components affecting the use of an Ethernet PHY externally connected to the module, as this will void the manufacturer's warranty. The phyCORE‑STM32MP15x can be ordered without Ethernet PHY if an external Ethernet PHY is to be connected

SOM Connector Pin | SOM Signal Name | Signal Level | Signal Type | Description |

|---|---|---|---|---|

| C29 | X_ETH1_RGMII_RXD0/PC4 | 3.3 V | I | ETH1 RGMII receive data 0 |

| C30 | X_ETH1_RGMII_RXD1/PC5 | 3.3 V | I | ETH1 RGMII receive data 1 |

| C31 | X_ETH1_RGMII_RXD2/PH6 | 3.3 V | I | ETH1 RGMII receive data 2 |

| C32 | X_ETH1_RGMII_RXD3/PB1 | 3.3 V | I | ETH1 RGMII receive data 3 |

| C33 | X_ETH1_RGMII_RX_CTL/PA7 | 3.3 V | I | ETH1 RGMII receive control (RX_DV + RX_ER) |

| C34 | X_ETH1_RGMII_RX_CLK/PA1 | 3.3 V | I | ETH1 RGMII receive clock |

| C36 | X_ETH1_RGMII_TXD0/PG13 | 3.3 V | O | ETH1 RGMII transmit data 0 |

| C37 | X_ETH1_RGMII_TXD1/PG14 | 3.3 V | O | ETH1 RGMII transmit data 1 |

| C38 | X_ETH1_RGMII_TXD2/PC2 | 3.3 V | O | ETH1 RGMII transmit data 2 |

| C39 | X_ETH1_RGMII_TXD3/PE2 | 3.3 V | O | ETH1 RGMII transmit data 3 |

| C40 | X_ETH1_RGMII_TX_CTL/PB11 | 3.3 V | I/O | ETH1 RGMII transmit control (TX_EN + TX_ER) |

| C41 | X_ETH1_RGMII_GTX_CLK/PG4 | 3.3 V | O | ETH RGMII transmit clock |

| C43 | X_ETH1_MDC/PC1 | 3.3 V | O | Ethernet management data clock |

| C44 | X_ETH1_MDIO/PA2 | 3.3 V | I/O | Ethernet management data I/O |

| C45 | X_ETH1_nINT/PG12 | 3.3 V | I | Ethernet interrupt (low active) |

| C46 | X_ETH1_RGMII_CLK125/PG5 | 3.3 V | I | External clock RX provided by the Ethernet PHY |

Note

It is strongly recommended to place the Ethernet PHY on the Carrier Board close to the pins of the SOM's Ethernet interface to achieve a trace length of less than 100 mm.

Tip

ETH_CLK is available at pins X1B57 (X_SPI1_MOSI/PB5 and X1D12 (X_USART3_RTS/PG8) of the phyCORE-Connector if an external Ethernet PHY is to be connected without quartz.

I2C Interface

The Inter-Integrated Circuit (I2C) interface is a two-wire, bidirectional serial bus that provides a simple and efficient method for data exchange among devices. The STM32MP15x contains several identical and independent multi-master fast-mode plus I2C modules. They are multiplexed with other signals. Please check the STMicroelectronics STM32MP15x Reference Manual for further information. One of these I2C modules (I2C4) is used on the phyCORE STM32MP15x and is available at phyCORE-Connector X1. A second one (I2C1) is predefined for external usage. The following table lists the I2C ports on the phyCORE-Connector:

SOM Connector Pin | SOM Signal Name | Signal Level | Signal Type | Description |

|---|---|---|---|---|

| D21 | X_I2C4_SCL/PZ4 | 3.3 V | O | I2C4 SCL (clock out) with internal 2 kΩ pull-up to VDD, used for internal I2C devices (PMIC, RTC, EEPROM) |

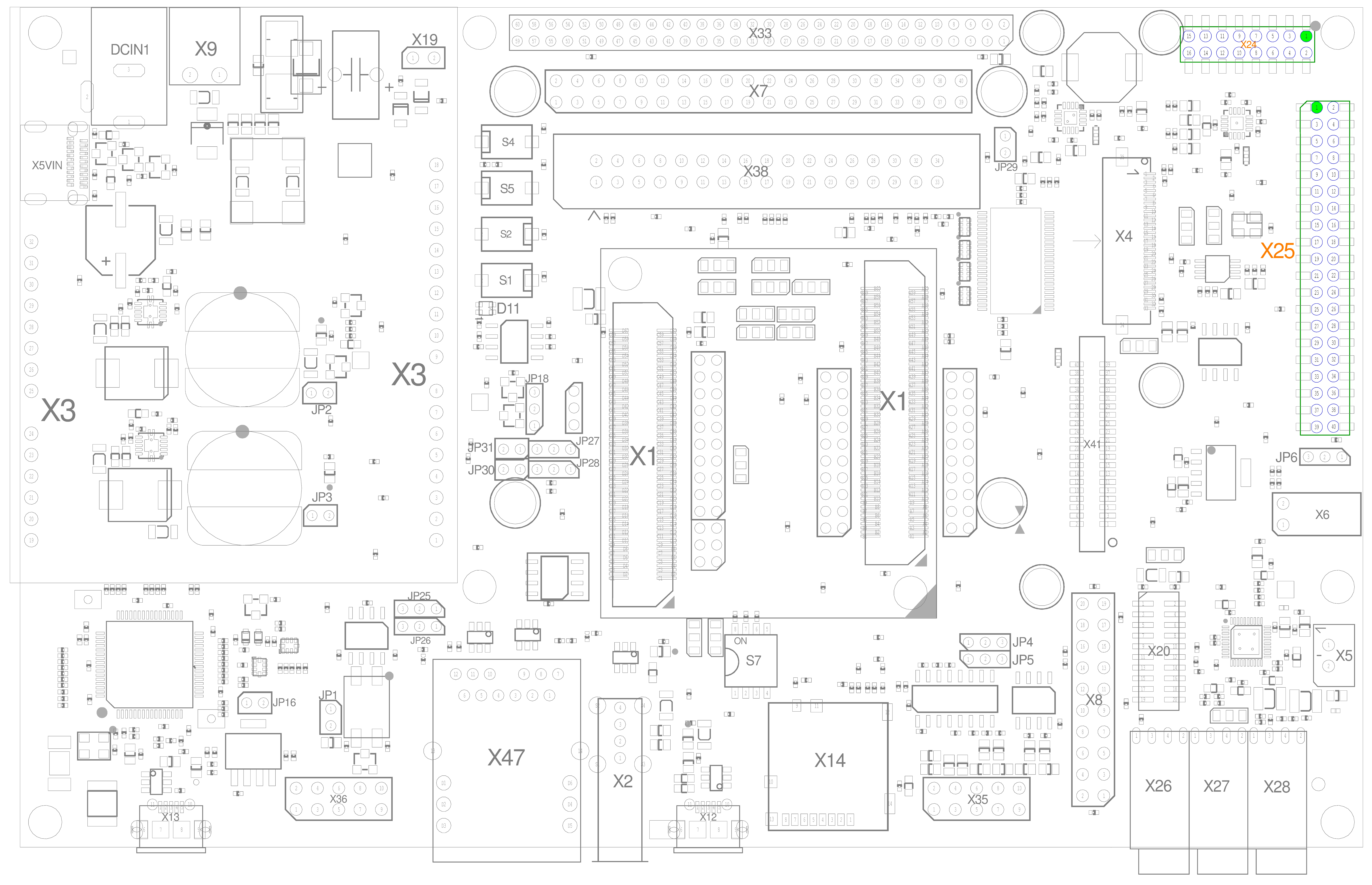

| D22 | X_I2C4_SDA/PZ5 | 3.3 V | I/O | I2C4 SDA (data I/O) with internal 2 kΩ pull-up to VDD, used for internal I2C devices (PMIC, RTC, EEPROM) |